Quantifying N2O Emissions at a Wastewater Treatment Plant

The greenhouse gas nitrous oxide (N2O) is emitted from various sources, including agriculture, land use, transportation, and wastewater treatment plants. N2O has a global warming potential 273 times greater than CO2 over a 100-year time frame. As such, there is a strong case for reducing N2O emissions from sources such as wastewater treatment plants, potentially through process optimization, the use of low-nitrogen technologies, and reducing nitrogen inputs into the system.

The United Nations Net Zero Coalition has set a 45% reduction in greenhouse gas emissions by 2030 as a goal, with the target to reach net zero emissions by 2050. As a result, industrial operations are required to quantify current emissions more accurately so that reductions through process optimization and other means can be correctly assessed.

The total emissions from complex industrial sites, such as wastewater treatment facilities, are not typically derived from measurements, either continuous or at prescribed intervals. Instead, emissions are estimated based on activity, throughput, or energy usage multiplied by prescribed emissions factors attributed to discrete equipment and processes that combine to make up the complete facility. Often, such emissions factors are based on inaccurate and outdated measurements and assumptions, contributing to an overall underestimation of total site emissions.

The primary source of N2O emissions from wastewater treatment plants is from the removal of nitrogen through the two-step biological process of nitrification, which is followed by denitrification. During nitrification, bacteria are used to remove nitrogenous compounds from wastewater; ammonia is converted first to nitrite and then to nitrate. Through denitrification, nitrate is further reduced to nitric oxide (NO), N2O, and nitrogen. Additional sources of N2O emissions from wastewater treatment plants include aeration systems, filter beds, sludge handling and storage, and nitrogen-rich waste streams.

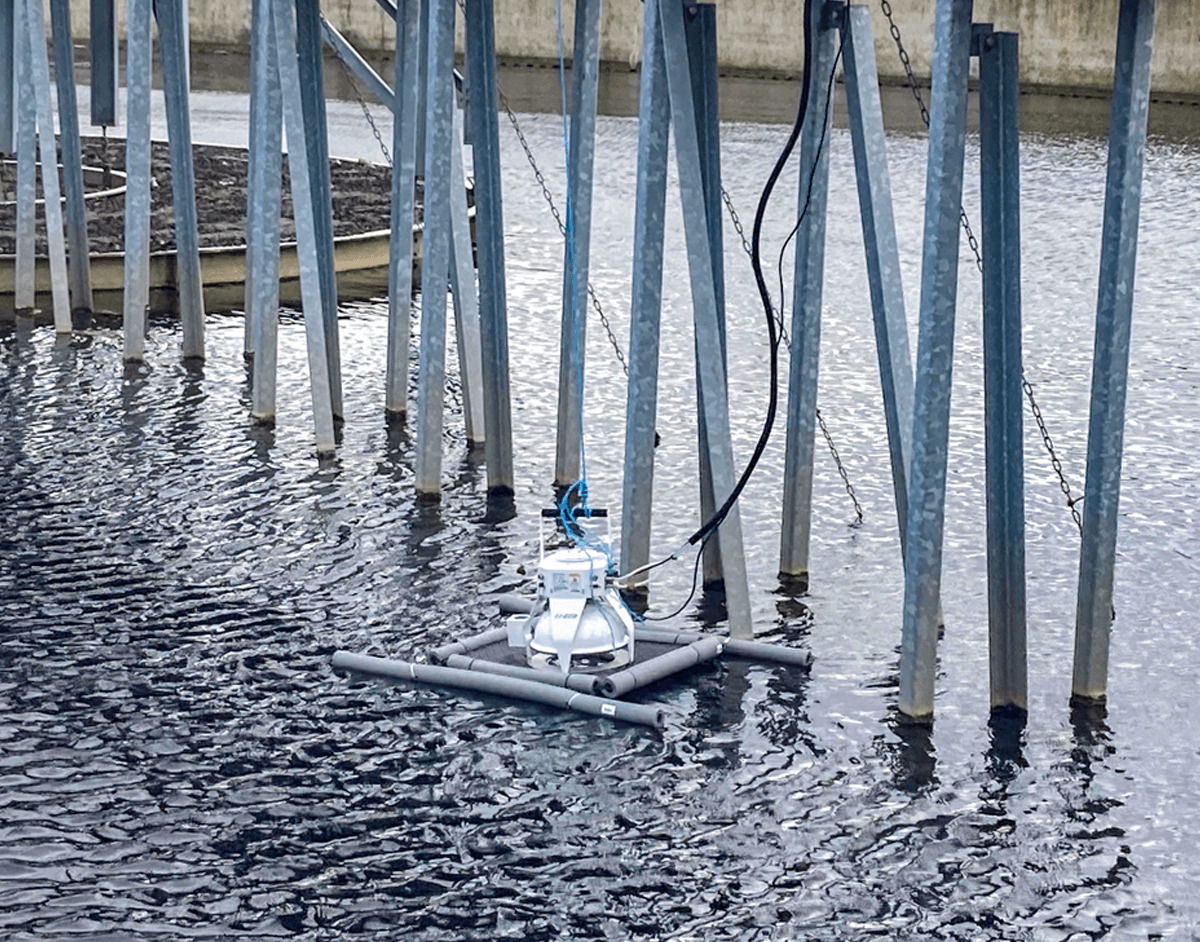

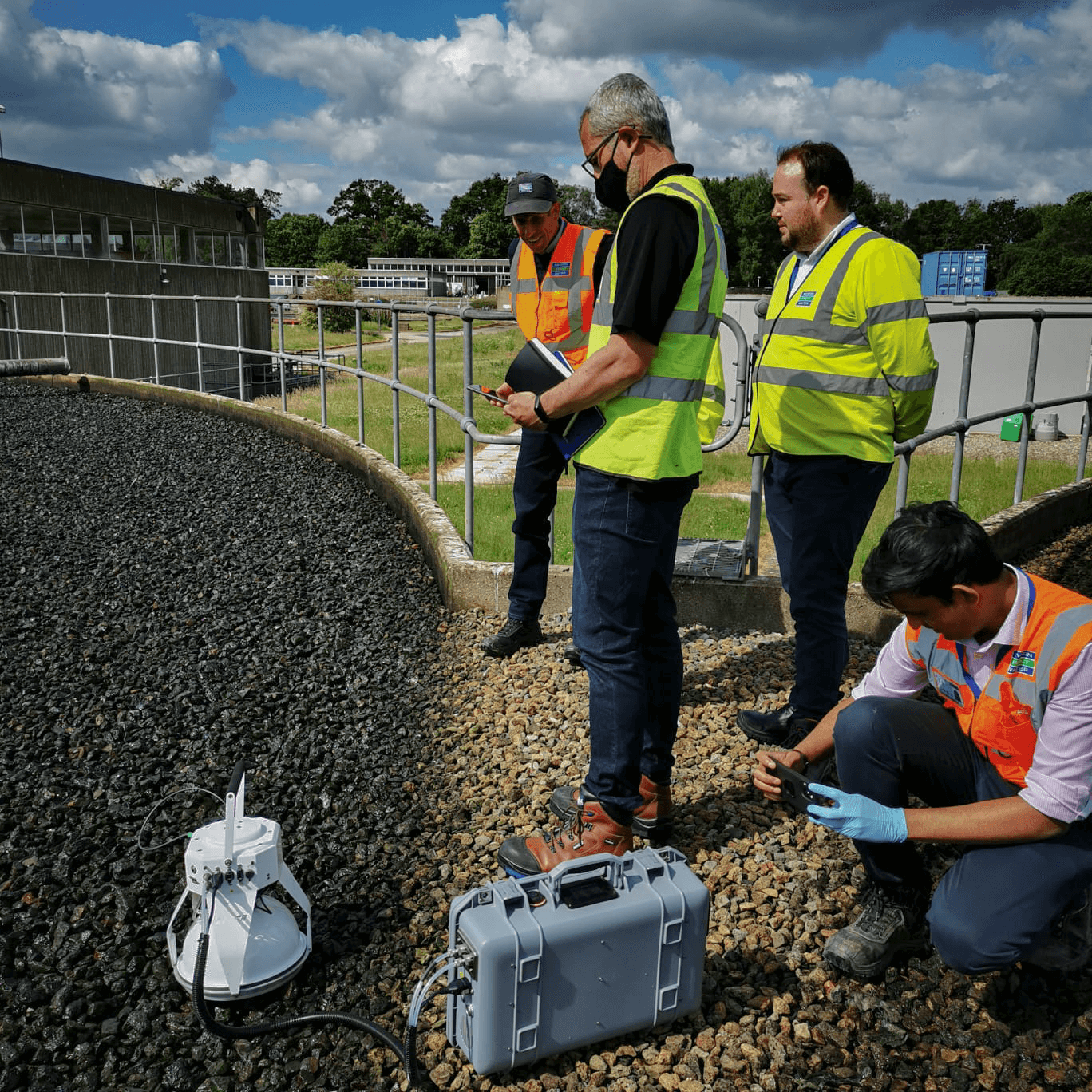

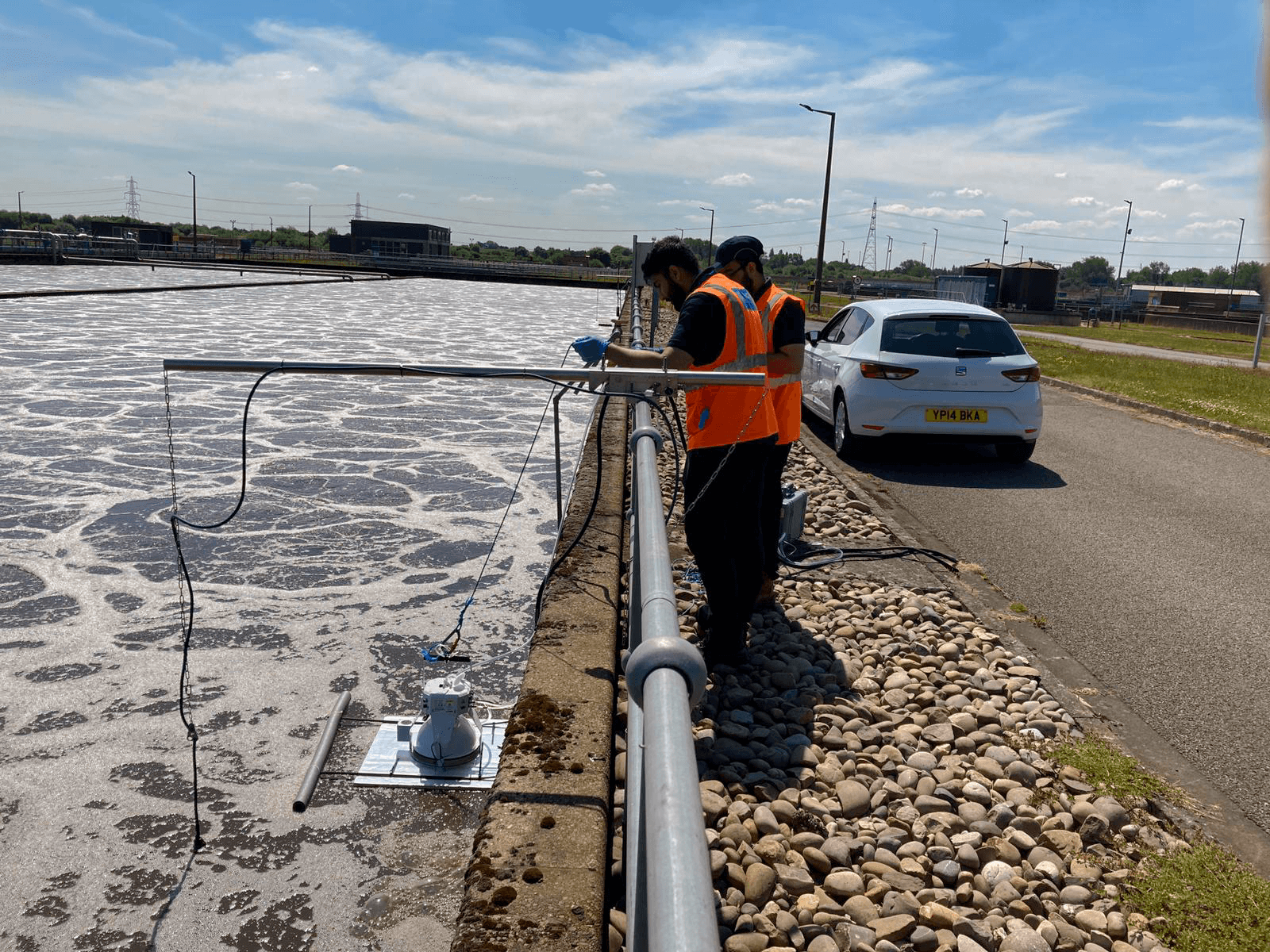

Severn Trent, a water company based in Coventry, England, and LI-COR Environmental co-developed a methodology for quantifying N2O emissions from an aerated denitrification channel system using a LI-7820 N2O/H2O Trace Gas Analyzer with an 8200-01S Smart Chamber that was deployed on a floating platform. The same system, minus the floatation device, was applied to other stages of the wastewater treatment process to provide an overall understanding of the location of N2O emissions and to quantify those emissions under variable water treatment load conditions. Measurements made using LI-COR instruments will be used to derive improved emissions factors that can be applied not only at the test site, but at all wastewater treatment sites using similar clean-up technologies.

The LI-7820 N2O/H2O Trace Gas Analyzer, based on Optical Feedback Cavity Enhanced Absorption Spectroscopy (OF-CEAS), delivers sub parts per billion measurement precision in 1 second in a rugged, portable design. When combined with the LI-COR Smart Chamber, this precision allows for the fast determination of very low fluxes of N2O at 0.05 nmol mol-1 m3 s-1 in less than 2 minutes. In its standard configuration, Severn Trent was able to use the LI-7820 and Smart Chamber to quantify N2O fluxes quickly across their site, with an integrated GPS receiver allowing the visualization of fluxes using standard GIS tools. Solid substrates such as cake beds and trickling filters can be approached in the same way as standard soil flux measurements, however the deployment of the system on an aerated denitrification channel presents a challenge beyond the floatation of the Smart Chamber.

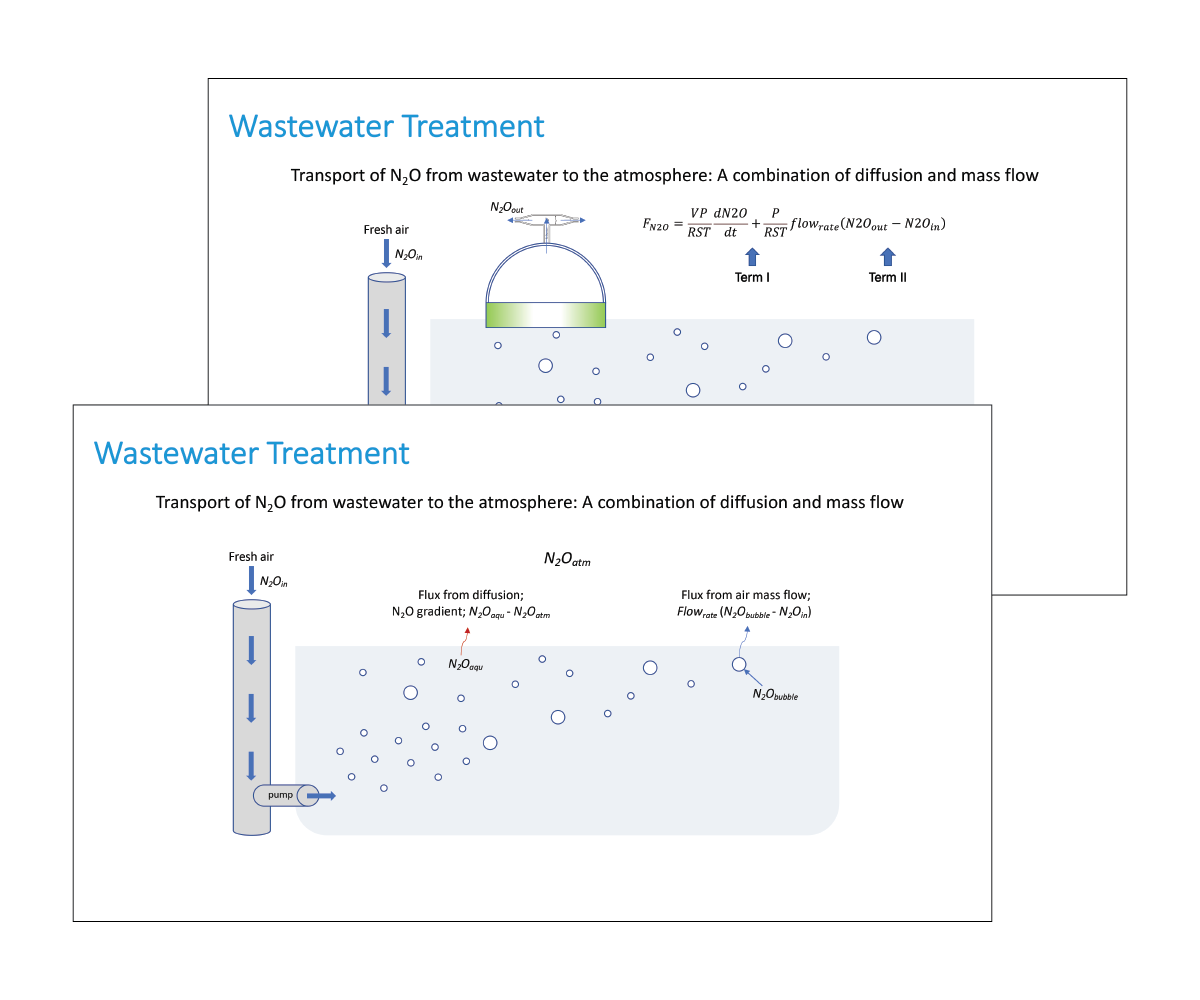

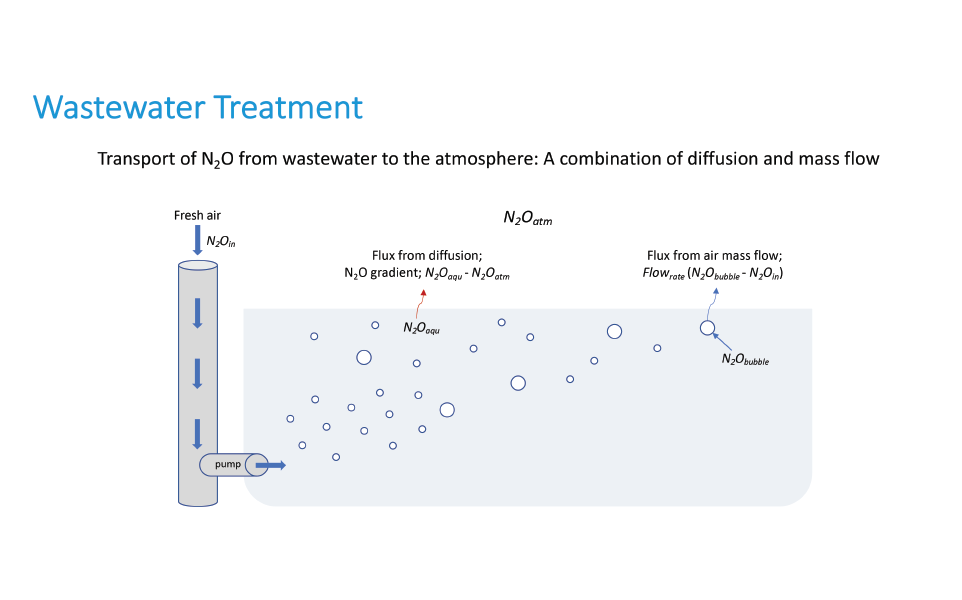

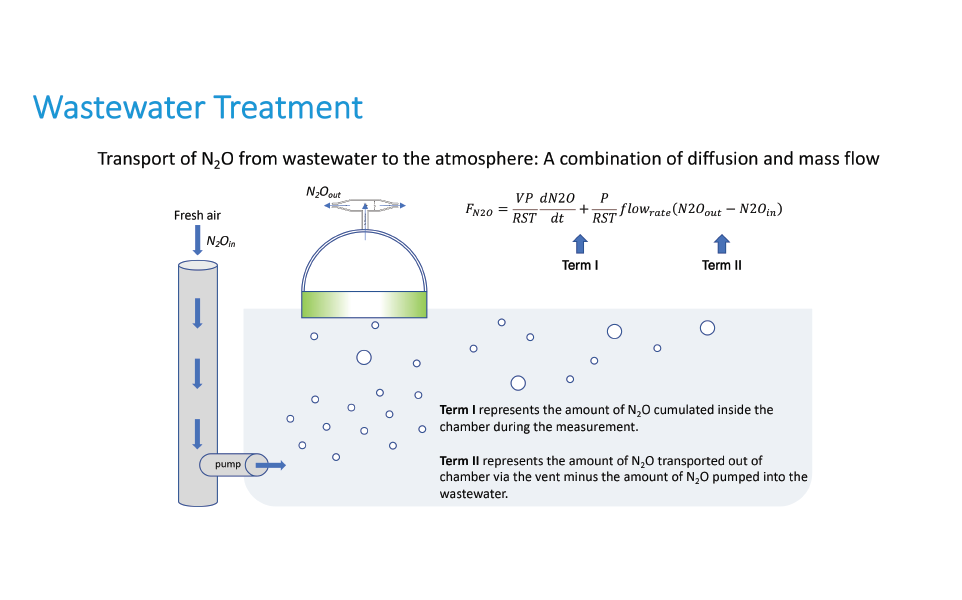

On a normal body of water, a lake for example, gas fluxes result from diffusion of the dissolved gas into the atmosphere above the surface. The situation mirrors that of soil, and standard flux calculations performed within the Smart Chamber can be applied. In the case of the aerated denitrification channel, in addition to N2O transport via diffusion, N2O is also driven from the water to the surface via the active aeration of the channel. In this case, the flux calculation must be modified to account for the additional aeration transport.

To address this, the Smart Chamber was adapted to incorporate a flow meter, allowing for the measurement of aeration flow through the chamber. The modified flux calculation, including this parameter, was then used to derive an accurate value for N2O flux from the system. Previously, N2O generation was quantified using liquid phase sensors that require much supplementary monitoring and ongoing maintenance. These sensors measure dissolved N2O rather than direct emissions, estimated using Henry’s Law. Here, for the first time, a wastewater treatment operator was able to directly and accurately measure N2O flux, comparing fluxes from location to location in real time.

The collaboration between Severn Trent and LI-COR Environmental is leading to a new methodology that can be applied across the industry, facilitating a better understanding of emissions from wastewater treatment plants. With more accurate information, operators will be better equipped to implement and assess the improved site management required to meet net zero commitments.