Using the Gill HS and R3 Anemometers in Eddy Covariance Systems

Printable PDF: Using the Gill HS and R3 Anemometers in Eddy Covariance Systems

(EC_InstallGuide_Gill_HS_R3-17988)

Download this content as a pdf that can be saved to your computer or printed.

This document describes how to use the Gill HS-50, HS-100, and R3-50 sonic anemometers in LI-COR eddy covariance systems, using the HS-50 as an example. The topics covered are installing the anemometer at your site, connecting the anemometer to the SmartFlux 2 or 3 System, and configuring the software for the eddy covariance site.

Important: Be sure to read and understand the documentation provided with the sonic anemometer.

Installing the anemometer and analyzer

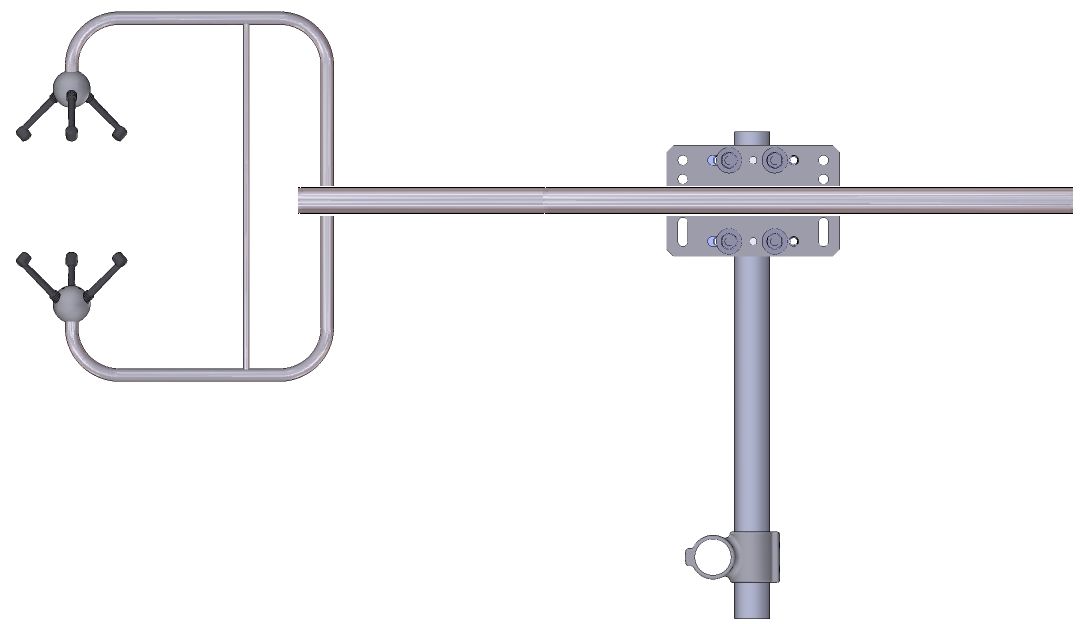

The HS-50 anemometer can be mounted to a horizontal cross-arm with a crossover fittings and post hardware. The R3-50 mounts with the mounting apparatus (7900-342).

Orientation, horizontal offsets, and vertical offset

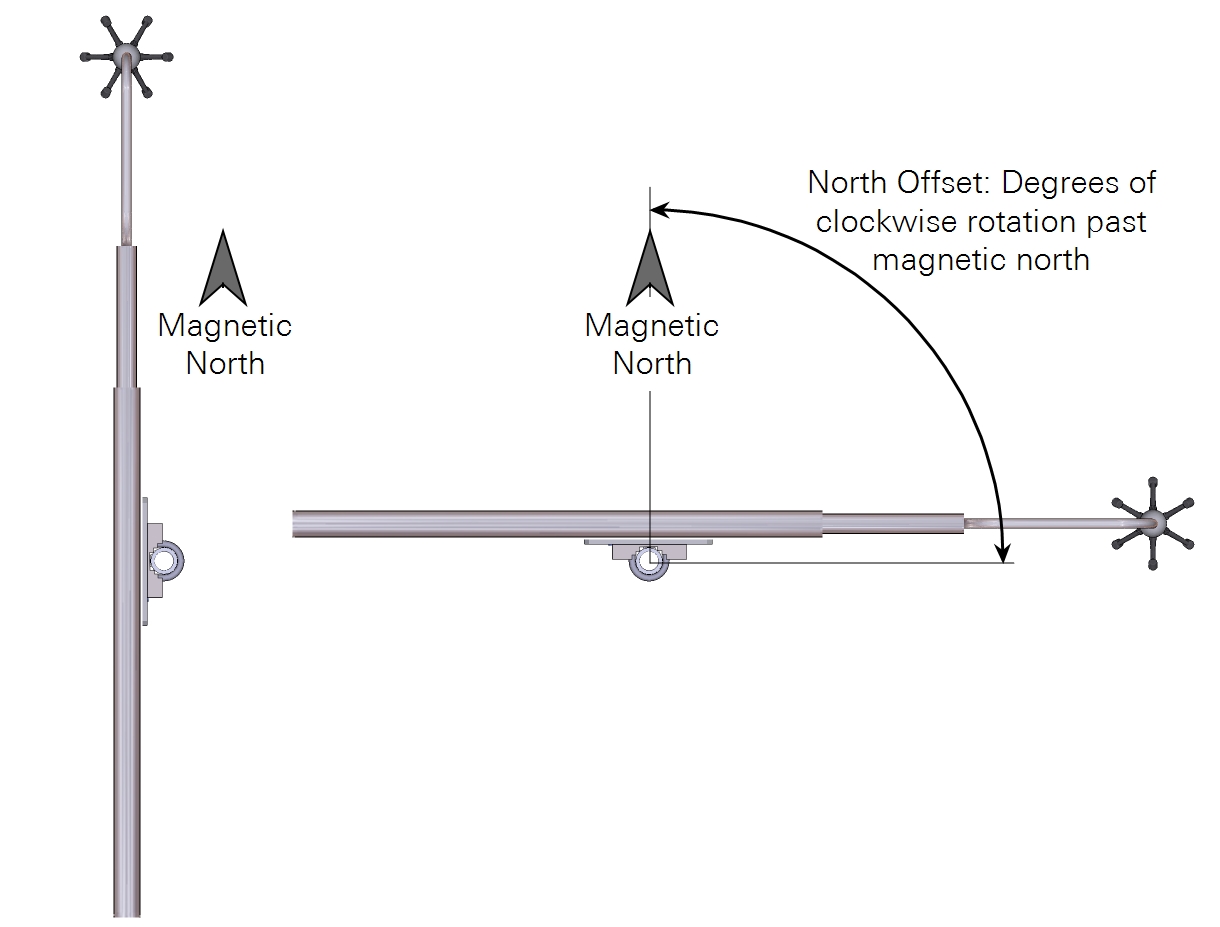

Mount the anemometer oriented toward magnetic north, then rotate it so that it faces the prevailing wind. Measure and record the north offset and height.

- North offset (°): The degrees of rotation from magnetic north.

- Height (m): The distance between the ground and the center of the anemometer sample volume.

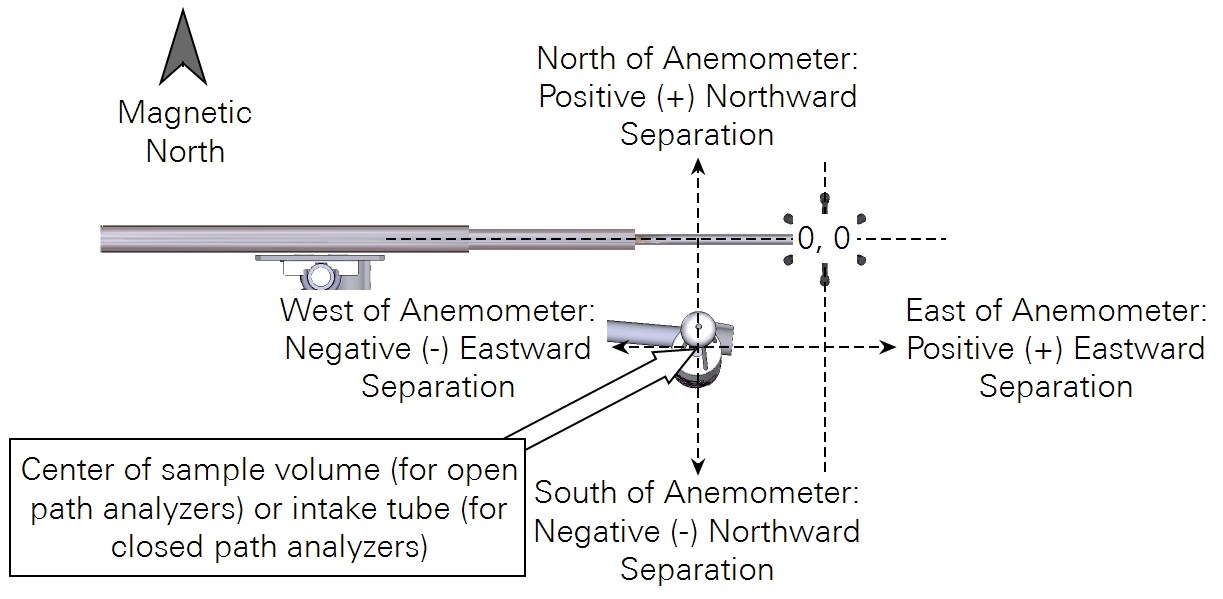

Horizontal separation distances (Figure 1‑3) are measured in a Cartesian coordinate system, which EddyPro® uses to determine the distance between the gas sample and the anemometer. The center of the anemometer is the center (0, 0) of the coordinate system. Distances from the anemometer are provided along the north-south and east-west axes. The sensor head or air inlet should be 10-20 cm from the anemometer in the horizontal plane.

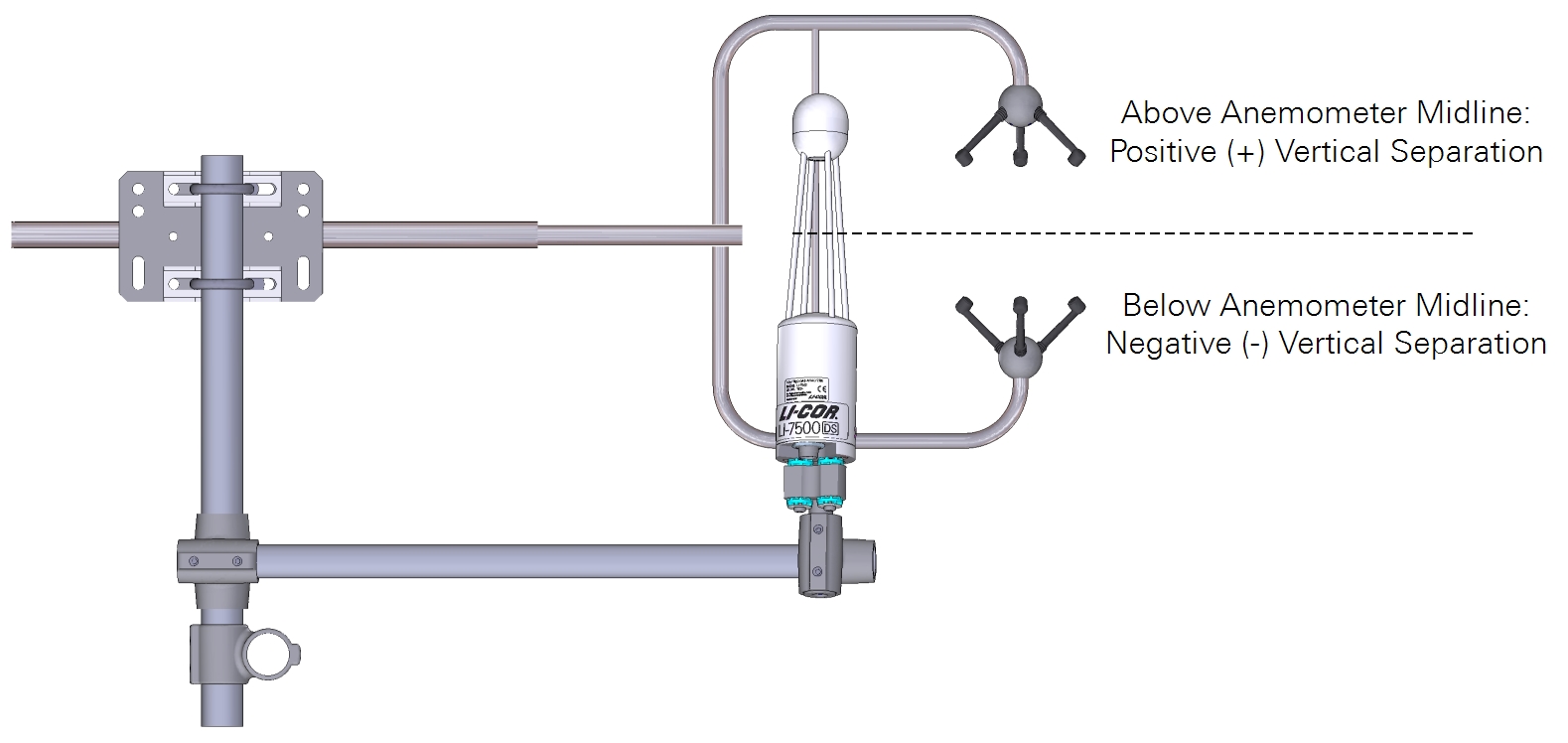

For deployments that are close to a plant canopy, the center of the analyzer and sonic anemometer should be at equal heights, as shown in Figure 1‑4. If mounted over 15 m above ground level, horizontal and vertical sensor separation can be as large as 30-50 cm. Measure and record the horizontal and vertical separation distances.

- Northward Separation (cm): North (positive values) or south (negative values) distance between the sample path or intake and the anemometer.

- Eastward Separation (cm): East (positive values) or west (negative values) distance between the sample path or intake and the reference anemometer.

- Vertical Separation (cm): Vertical distance between the sample path or inlet and the reference anemometer. Negative if the center of the analyzer or the inlet is below the center of the reference anemometer sample volume; positive if the inlet is above.

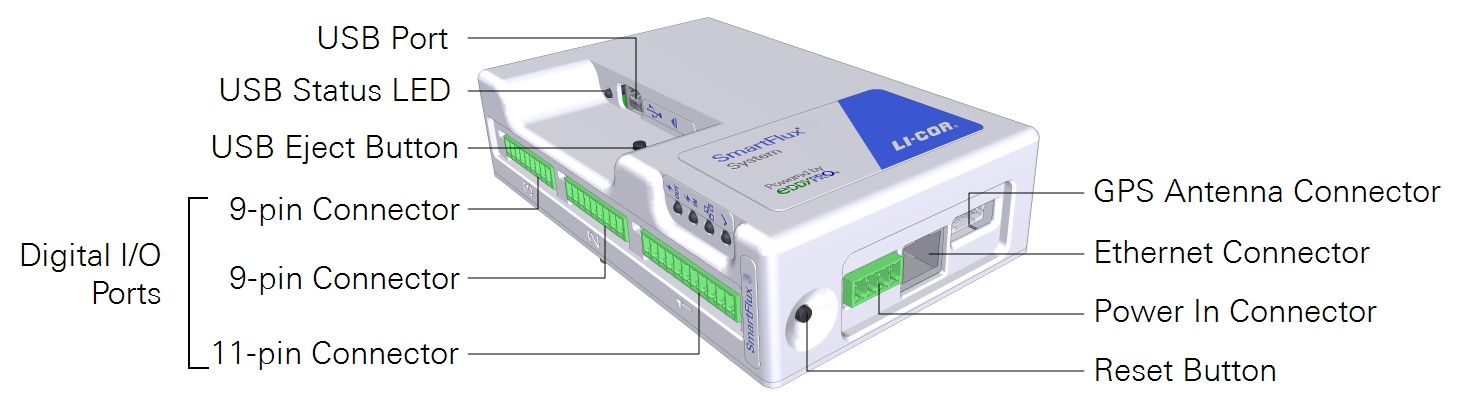

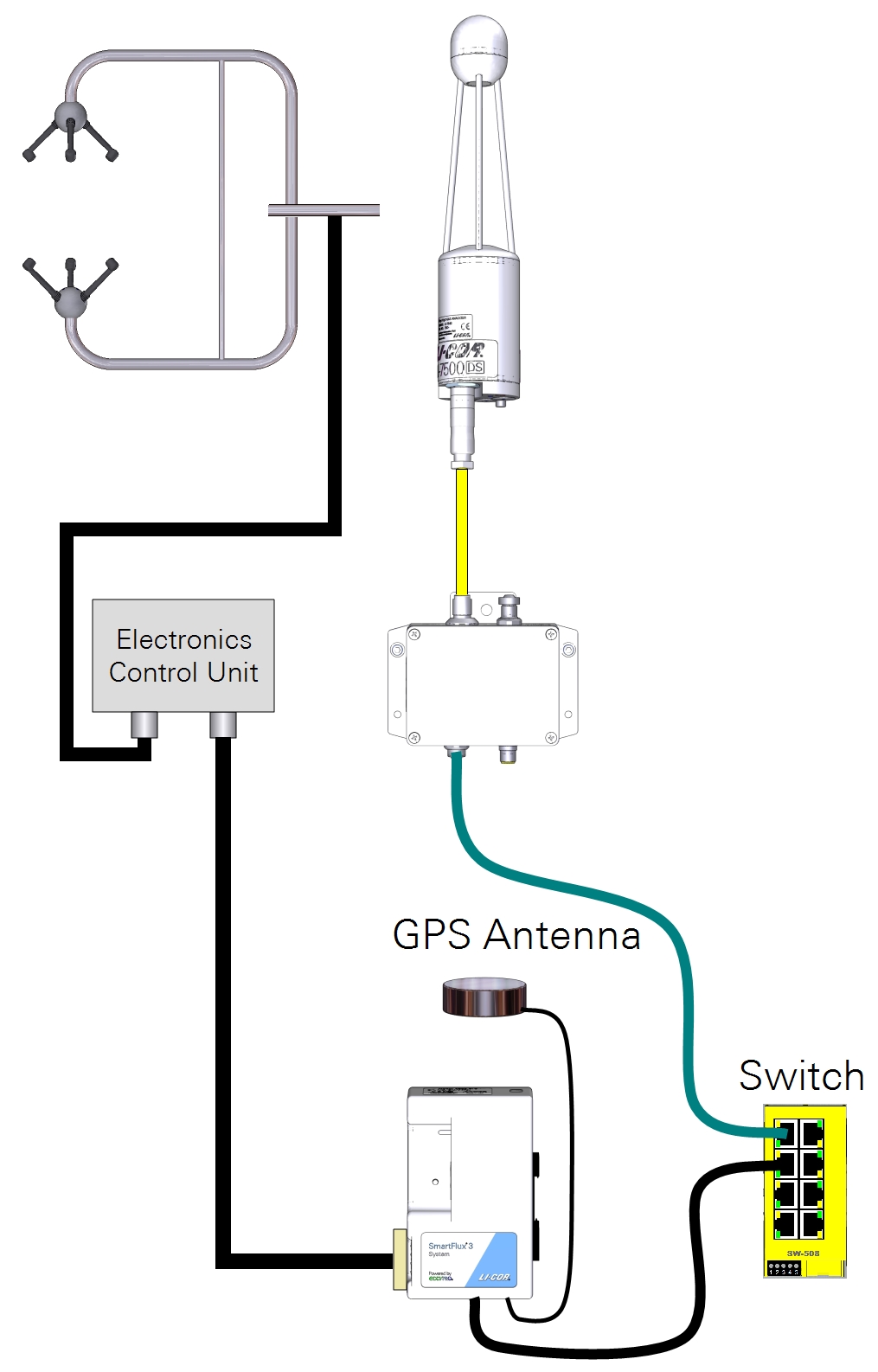

Connecting to the SmartFlux 2 or 3 System

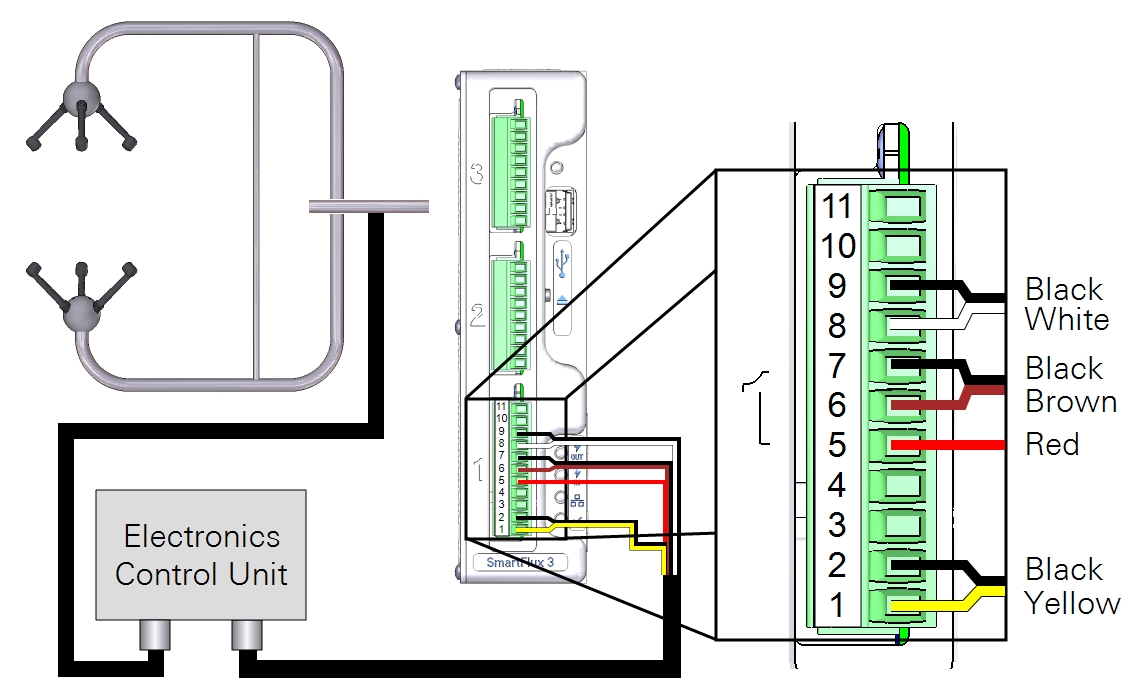

The anemometer is automatically configured by the SmartFlux System when connected and powered on. The anemometer cable connects to port 1, 2, or 3 on the SmartFlux System (port 1 shown). Port 1 accepts 11-pin and 9-pin terminal strips. Ports 2 and 3 accept 9-pin terminal strips.

Important: Disconnect the power supply to the SmartFlux System before connecting anemometer cables.

| SmartFlux Terminal | SmartFlux Label | Wire Color |

|---|---|---|

| 9 | RS-422/485 RX- | Black (bundled with white) |

| 8 | RS-422/485 RX+ | White |

| 7 | RS-422/485 TX- | Black (bundled with brown) |

| 6 | RS-422/485 TX+ | Brown |

| 5 | Signal Return | Red |

| 2 | Power Out (-) | Black (bundled with yellow) |

| 1 | Power Out (+) | Yellow |

Important: At least 13 VDC must be supplied when using a 50 meter power cable because of voltage drops.

Configuring the eddy covariance system

Several things need to be configured in software before your system will log valid eddy covariance data sets. These are described below.

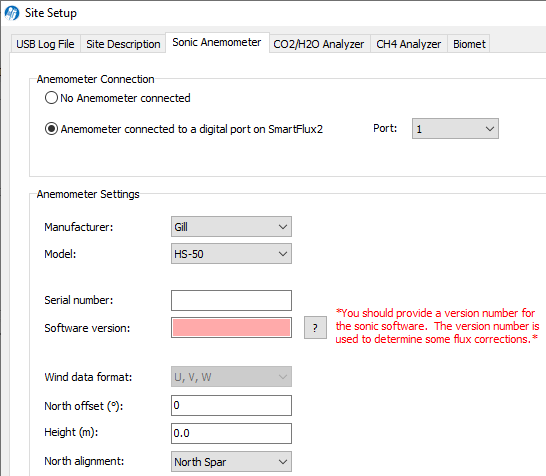

Enter sonic anemometer information

In the gas analyzer PC software, click Site Setup > Sonic Anemometer tab, and select Anemometer connected to a digital port on the SmartFlux 2 or 3 System.

- Port: The port on the SmartFlux system that the anemometer is connected to (1 in this example).

- Manufacturer: Gill .

- Model: HS-50, HS-100, or R3-50.

- Serial Number: Optional, the anemometer serial number.

- Software Version: Optional, the anemometer software version.

- Wind Data Format: U, V, W is the only option.

- North Offset: Degrees clockwise of magnetic North. Measured at the site (see Figure 1‑2).

- Height: Distance of the anemometer sample volume above the ground. Measured at the site.

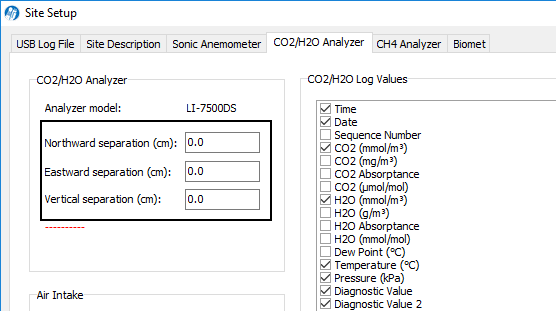

Enter gas analyzer information

The following information is required:

- Northward Separation (cm): Measured at site (Figure 1‑3).

- Eastward Separation (cm): Measured at site (Figure 1‑3).

- Vertical Separation (cm): Measured at site (Figure 1‑4).

Additional system settings

Although not related to the sonic anemometer, configure the following settings to finish configuring the eddy covariance system. Under Site Setup > USB Log File > USB Log File Options, set the following:

- Log Rate (Samples per Second): 10.0 (or higher).

- File Duration: 30 minutes.

Under Site Setup > Site Description, set the following:

- Site Name: A name of your choice.

- Station Name: A name of your choice.

- Canopy Height (m): The distance between ground level and the top of the plant canopy.

- Check Use SmartFlux GPS coordinates.

At this point, you've configured the minimum required settings to log complete eddy covariance data sets with an LI-7500A/RS/DS. There are additional settings to configure if you are using an LI-7200/RS, a biomet system, or an LI-7700, or if you want to process data using EddyPro Advanced settings. These are described in corresponding product documentation.