Maintaining the soil chamber

Here we describe basic maintenance for the soil chamber. System maintenance procedures are described in Maintenance and calibration

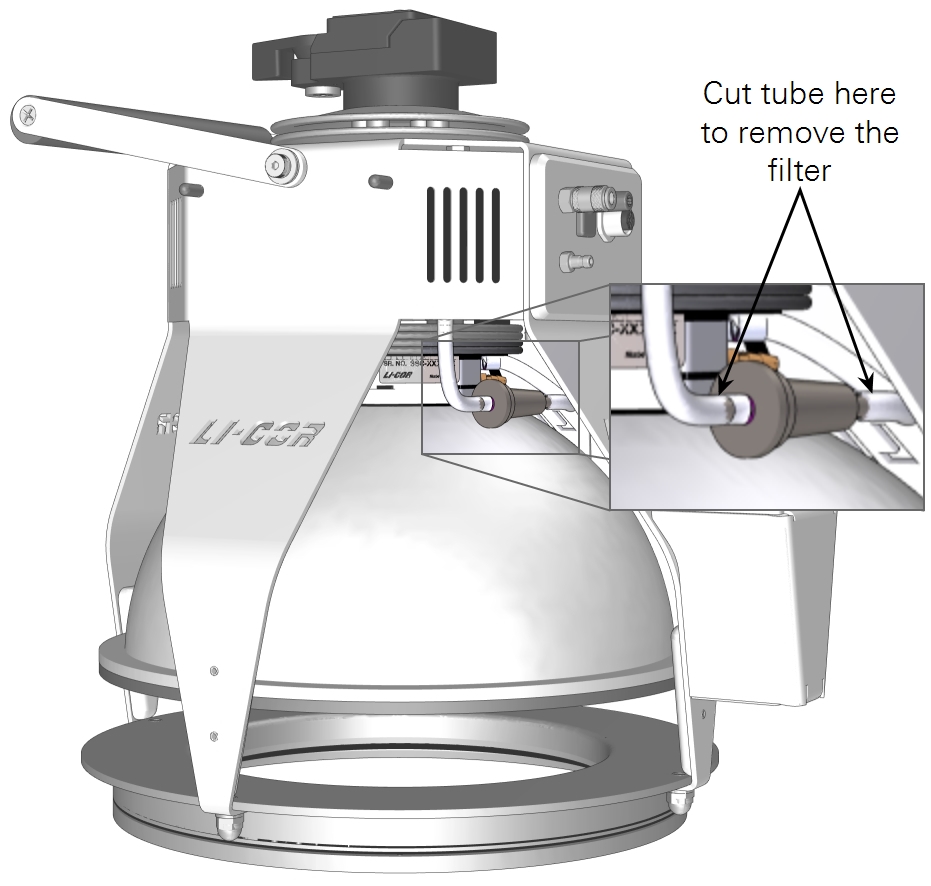

Replacing the bellows pump air filter

There is one air filter in the pneumatic circuit that drives the bellows. The filter can become clogged, which will affect the performance of the pump. Do not run the pump if you think the filter is clogged. Doing so can damage the pump. To replace the filter:

Locate the filter. If you are careful, you can cut the bev-a-line tubing to remove the old filter and install the new filter in place of the old one. If you find that the tube is too short after cutting it, acquire some urethane tubing and cut one or two pieces to use in place of the old ones. The filter is not reusable. It can be disposed of with municipal waste. Install a new filter from the accessories kit.

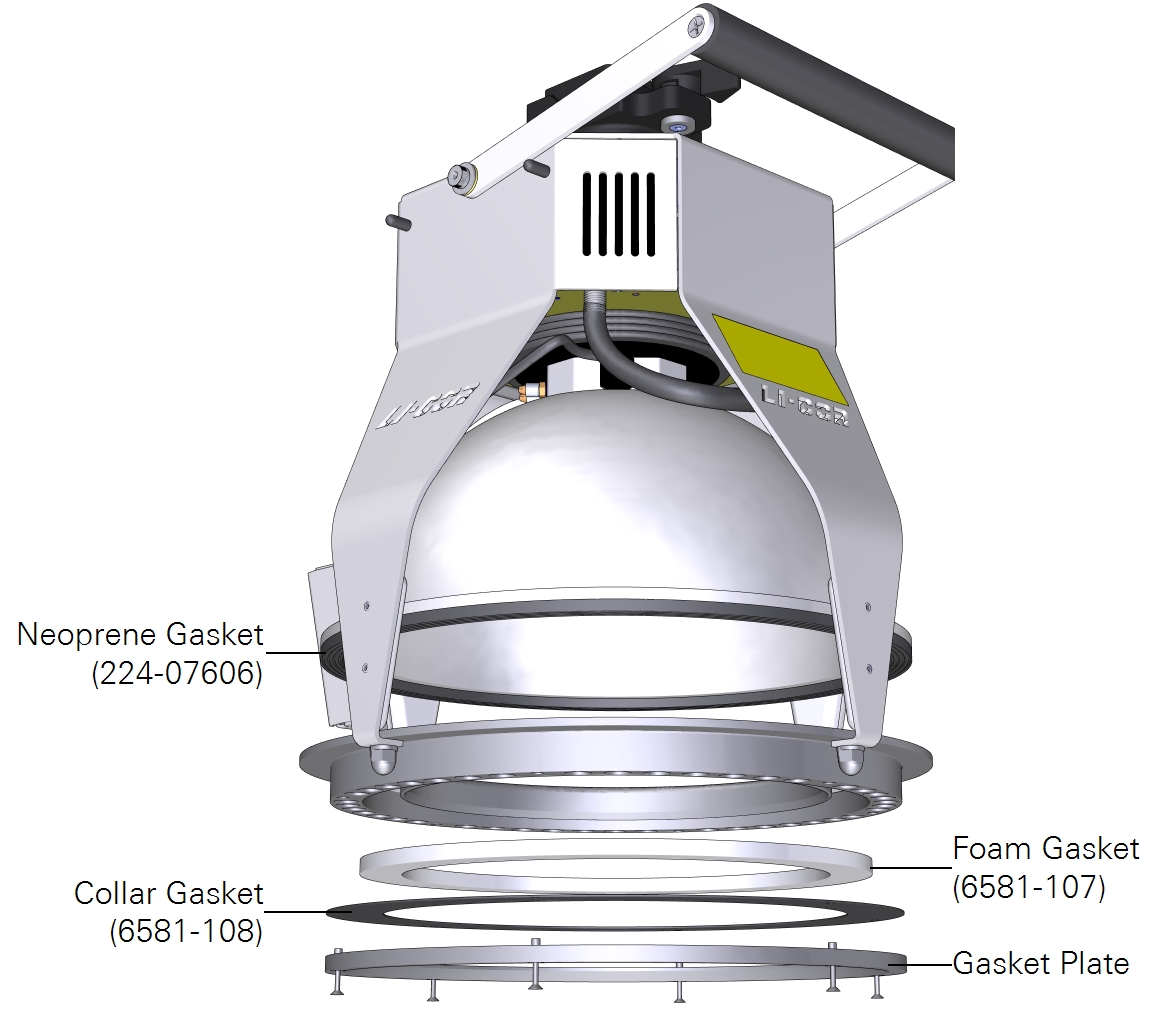

Maintaining the gaskets

The soil chamber uses three gaskets to seal the chamber during a measurement. One is a black neoprene gasket (part number 224-07606) that is located on the bottom of the chamber bowl. This gasket will not require maintenance typically, unless it is physically damaged during use. The other two gaskets are on the bottom of the chamber, beneath the metal flange that surrounds the soil collar. These two gaskets, especially the white foam gasket, may need to be replaced more regularly.

Foam gasket

The foam gasket is the most easily damaged. Inspect the foam gasket before you start making measurements each day. If the foam is torn or compressed, or if it appears as though the foam will not make a good seal you should replace it.

You do not need to remove the gasket plate when replacing the foam gasket. Simply pry it out with a blade or screw driver and press the new one in place. In some cases, you can reuse a foam gasket by flipping it over.

Work the gasket into place with your fingers. Be careful not to stretch the gasket. Be sure it is seated all the way and that it lays flat in the flange.

Collar gasket

The collar gasket should not need to be replaced unless it is torn. To replace the gasket, loosen each of the six gasket plate screws until the plate is free of the chamber. Remove the plate and old gasket. Align the new gasket with the screw holes and reassemble the chamber.

Neoprene gasket

The bottom of the bowl has a neoprene gasket that forms a seal when the chamber is closed. The gasket should be replaced if it has visible damage or if you determine that it no longer forms a seal when the chamber is closed.

- Remove the four cap nuts and washers from the bottom of the chamber supports.

- Gently move the supports out slightly so they are clear of the bottom plate assembly, and remove the bottom plate assembly.

- Remove the damaged gasket from the bowl.

- You can pull it off or use a razor blade to trim it. Be careful not to damage to the finish. Clean the chamber surface with alcohol to remove any adhesive residue.

- Cut a piece of new gasket material to a length of about 63 cm.

- Remove the adhesive backing from the new gasket and install the gasket around the bottom of the chamber bowl.

- Trim the ends of the gasket so both sides are touching, then apply Loctite to glue the ends together.

- Reassemble the chamber.