Controller tests

The controller tests serve the following purpose: if you observe that the instrument is not controlling some parameter (e.g., CO2_s) in an expected manner even after passing the warmup tests (i.e. chemicals checked, zeroes checked, etc.), then run the associated controller test for that parameter. Controller tests do not need to be run each day.

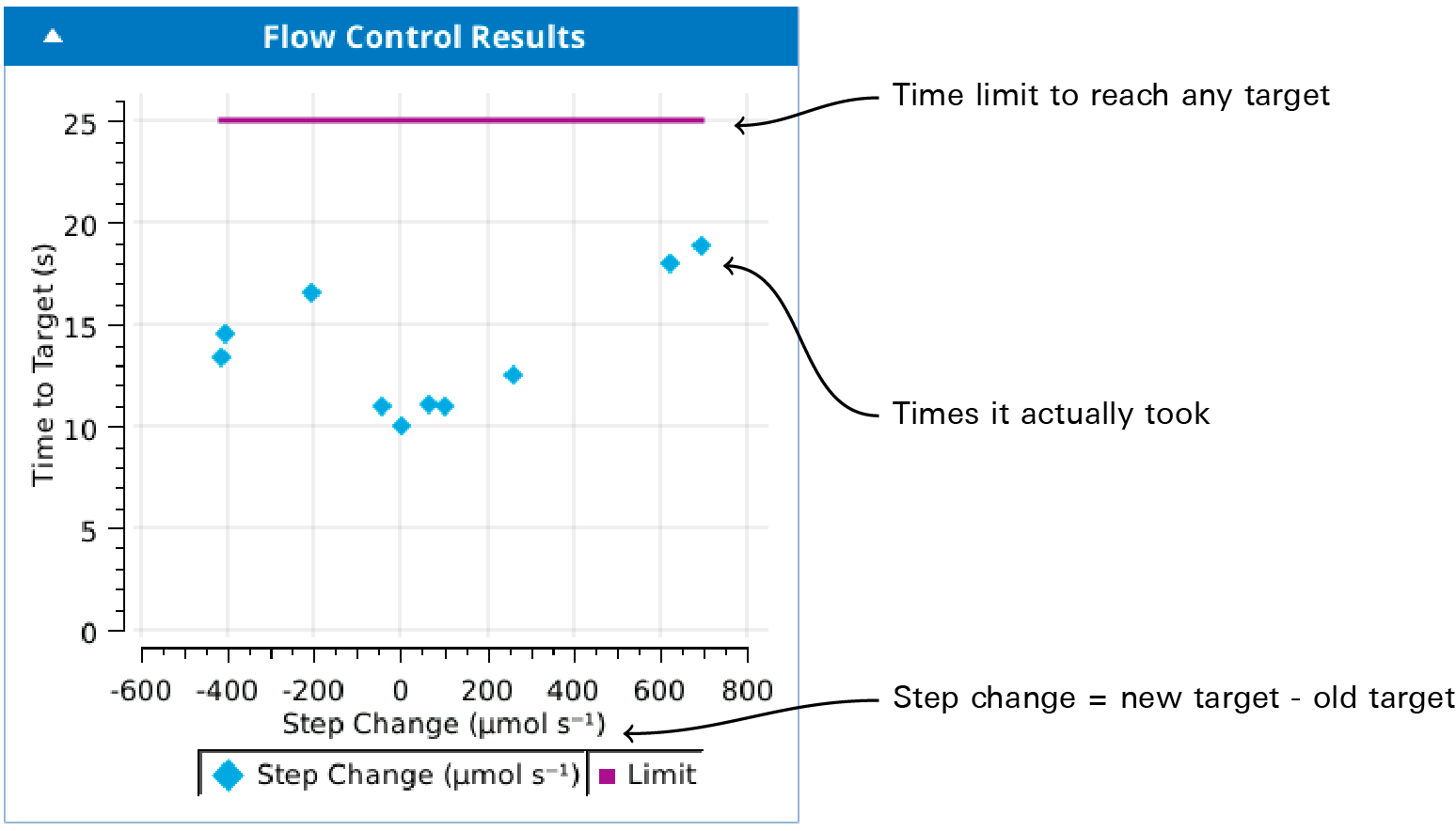

The controller tests have a common protocol: do a series of setpoints, randomly chosen, and note how long it takes the system to equilibrate at the new target. Failures result when the system is unable to stabilize at the new target in some prescribed amount of time.

There may be occasional failures, depending on the step change the happens to be come along, so don’t be concerned if that happens now and again. Consistent and repeated failures would indicate a problem, however.

Sample results are below, from the Flow Controller test.

Pass Test 1: Is Flow within 2 of 694 µmol s-1? Measured 693.867 after 18.9 s

Pass Test 2: Is Flow within 2 of 759 µmol s-1? Measured 759.14 after 11.1 s

Pass Test 3: Is Flow within 2 of 762 µmol s-1? Measured 762.038 after 10.0 s

Pass Test 4: Is Flow within 2 of 355 µmol s-1? Measured 355.008 after 14.5 s

Pass Test 5: Is Flow within 2 of 978 µmol s-1? Measured 977.994 after 18.0 s

Pass Test 6: Is Flow within 2 of 563 µmol s-1? Measured 563.21 after 13.4 s

Pass Test 7: Is Flow within 2 of 823 µmol s-1? Measured 822.936 after 12.5 s

Pass Test 8: Is Flow within 2 of 927 µmol s-1? Measured 927.192 after 11.0 s

Pass Test 9: Is Flow within 2 of 721 µmol s-1? Measured 720.918 after 16.6 s

Pass Test 10: Is Flow within 2 of 677 µmol s-1? Measured 676.836 after 11.0 s

Failed controller tests produce warnings with these suggestions:

An occasional failure, especially after a large step change, can be ignored.

Consistent and repeated failures should be investigated.