Maintenance

The section describes maintenance procedures for the gas analyzer and components.

Cleaning the gas analyzer optical path

Important: Power off the gas analyzer (disable the power supply or disconnect the power cable) before conducting any maintenance that involves disassembly or disconnecting cables. Disassembling the instrument or detaching or attaching head cables while the instrument is powered on may damage the instrument or result in a loss of data.

The upper and lower optical windows should cleaned when necessary (visible dirt or stains, or smaller than expected CO2 Signal Strength).

The windows are sapphire, and are extremely durable and resistant to scratches; clean the windows with any mild detergent or glass cleaner. Also, coating the windows with a water resistant windshield type coating (such as Rain-X®) or a high quality automobile type wax may help prevent droplets from remaining on the windows during rainstorms. Mounting the sensor head at a 10 to 15° angle from vertical will help prevent water from pooling on the window (see Figure 9‑1 ).

Changing the SmartFlux 3 System fuses

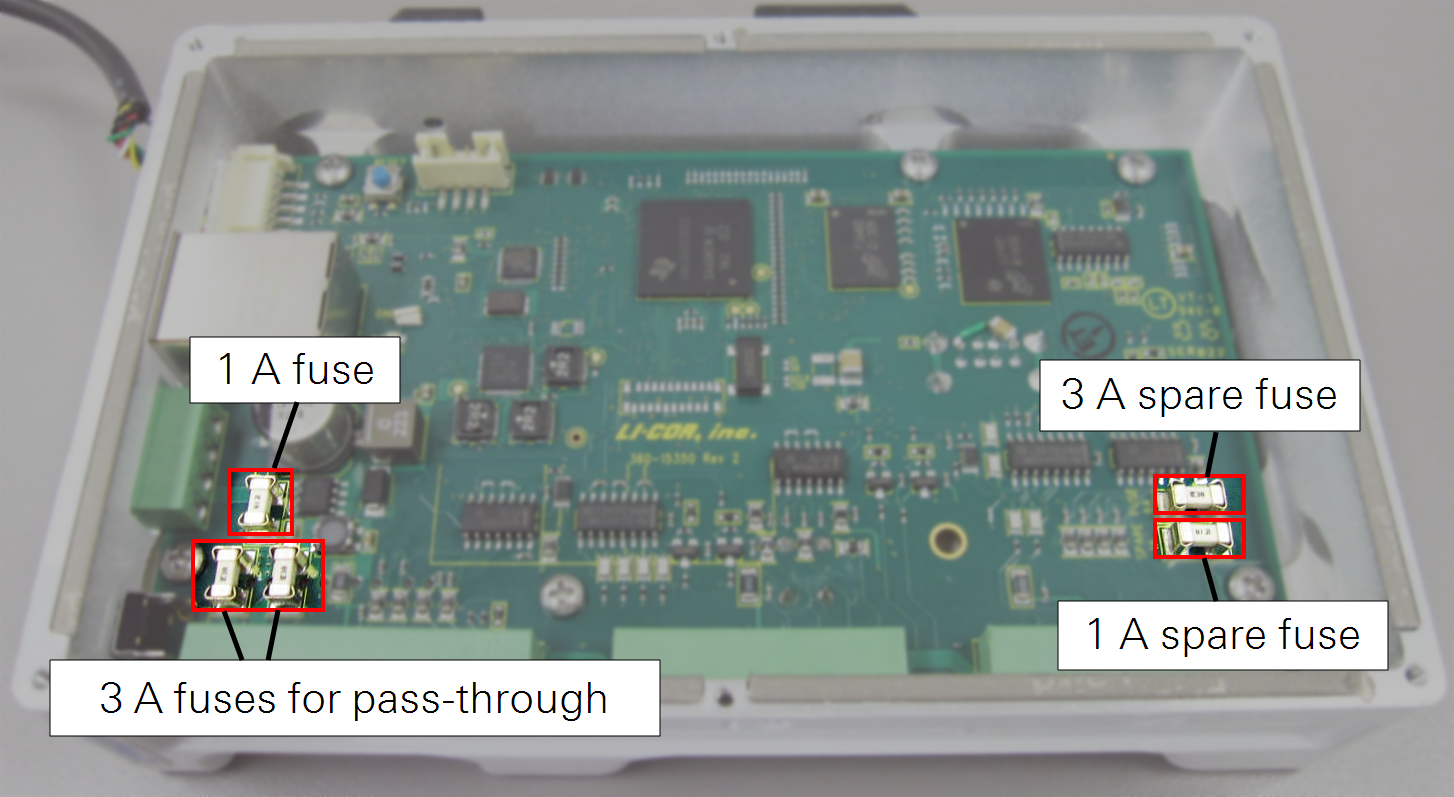

Power for the SmartFlux System and the pass-through power supply are protected by fuses. This section describes how to replace a blown fuse. Pass-through power flows through the SmartFlux System to pins on ports 1, 2 and 3 to power a connected sonic anemometer. To change the fuses, power off the SmartFlux System. Remove the power and data terminal strips. Remove the six screws on the side of the case and remove the case lid.

Important: Take care to avoid damaging nearby electronic components when removing fuses. Especially avoid prying on top of other electronic components.

3.0 Amp fuse for pass-through power

The SmartFlux System uses two 3.0 A fuses between the Power IN connector and the serial ports (see Figure 9‑2). One of these fuses is for the power wire to the anemometer or other connected device. The other 3.0 A fuse is for the power return wire and protects the system in case problems such as improper grounding cause a power surge.

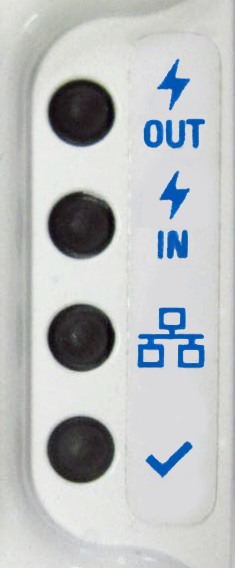

If the SmartFlux System boots up and has power, but the Power OUT LED does not light up, it is likely that one of the two 3.0 A fuses has failed.

- Measure both 3.0 A fuses with an ohmmeter. If one of them is an open circuit, replace it with the spare 3.0 A fuse.

- Remove the failed fuse and the spare 3.0 A fuse by gently prying under each fuse with a small flat-bladed screwdriver.

- Gently press the good (spare) fuse into the fuse holder. If both 3.0 A fuses are blown, you will need to order another 3.0 A fuse (part number 348-16020).

- Replace the lid and six screws on the SmartFlux 2 case.

Important: A blown 3.0 A fuse usually indicates a wiring problem between the SmartFlux System and the sonic anemometer or other connected device. Check for proper system grounding and remove possible causes of a short circuit in the power cable for the connected device. Also, while this fuse is rated at 3.0 A, keeping power use at 2.0 A or less will ensure a nearly unlimited lifetime for the fuse.

1.0 Amp fuse

If the Power OUT LED lights up, but the Power IN LED does not light up, it is likely that the 1.0 A fuse has failed (see Figure 9‑2).

- Measure the 1.0 A fuse with an ohmmeter. If it is an open circuit, replace it with the spare 1.0 A fuse (part number 348-13880).

- Remove the failed fuse and the spare 1.0 A fuse by gently prying under each fuse with a small flat-bladed screwdriver.

- Gently press the good (spare) fuse into the fuse holder.

- Replace the lid and six screws on the SmartFlux case.

Important: A blown 1.0 A fuse may indicate a problem with the SmartFlux 2 or 3 System. If the spare 1.0 A fuse also fails when installed, contact LI-COR support.

Replacing the internal chemicals

Important: Power off the gas analyzer (disable the power supply or disconnect the power cable) before conducting any maintenance that involves disassembly or disconnecting cables. Disassembling the instrument or detaching or attaching head cables while the instrument is powered on may damage the instrument or result in a loss of data.

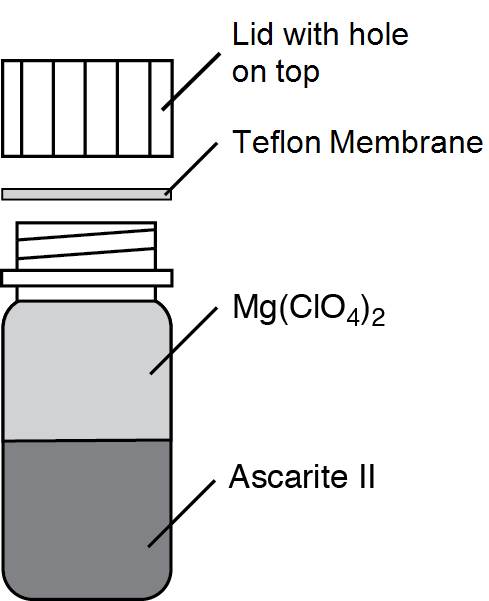

There are two small plastic bottles, each containing Ascarite II and magnesium perchlorate, in the analyzer housing that keep the optics free of CO2 and water vapor. These bottles should be replaced annually (or every 6 months in hot, humid climates). Replacement bottles are available from LI-COR in sets of two (part number 7500-950). If you want to recharge the bottles yourself, you can acquire the of Ascarite II and magnesium perchlorate from another source.

Note: Calibration shifts will occur if CO2 or H2O are not kept out of the analyzer housing.

To change the sensor head scrubber chemicals:

- Remove the chemical bottles.

- The plastic bottles are in the lower analyzer housing in the sensor head. Remove the mounting bracket from the analyzer. Then remove the thumbscrew and thread it into a cap. Pull straight out to remove the plug.

- Figure 9‑3. Remove the thumbscrew, thread into a bottle cover, and pull to remove the bottle cover.

- Remove the lids (with holes) from the old bottles and install the lids on the new bottles.

- The bottles that are to be inserted into the analyzer must have lids with holes to ensure that the air inside the analyzer is scrubbed of CO2 and water vapor.

- Be sure that Teflon membrane is in place to keep the chemicals from spilling.

- Insert the new bottles into the analyzer housing cap first.

- Replace the bottle covers and the cover retention screw and reattach the mounting bracket.

- After installing, allow at least 24 hours (with the instrument powered on) to scrub the housing; otherwise, the instrument may still drift for a time as CO2 and H2O are scrubbed from the analyzer.

- This should be followed by setting the CO2 and H2O zeros. Check the zero again, if possible, after one or two days.

Note: Read the technical note called "Using CO2 and H2O Scrubbers with LI-COR Gas Analyzers" for information about the interactions between scrub chemicals and the air.

See https://licor.app.boxenterprise.net/s/7i418s3uhd2uamoxfmjd.

Software updates

Go to licor.com/support/LI-7500DS/software.html for the latest versions.

We recommend running the most current software at all times including both the embedded and interface software for the LI-7500DS, EddyPro, and embedded software on the SmartFlux System.

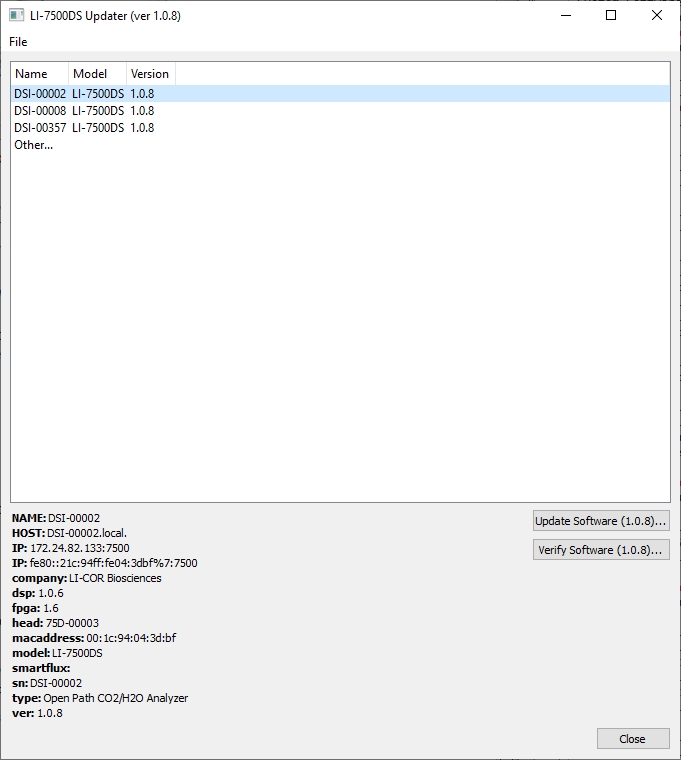

Embedded instrument software update

To update the embedded instrument software:

- Power up the gas analyzer. Connect your computer using an Ethernet cable.

- Install the LI-7500DS Updater application on your computer.

- Launch the application and select the LI-7500DS from the list.

- Click Update Software.

- The update will take about 5 minutes.

- Important: Do not close the software, let your PC go to sleep, or power off the instrument during the update process. The software will notify you when the update is complete. If the update fails for any reason, repeat steps 2 and 3.

- After updating the software, check all your instrument configuration settings. The instrument should retain all settings through a software update, but it is always a good idea to make sure everything is set the way you expect.

Windows interface software update

To update the Windows interface software for gas analyzers:

- The Windows interface software is an executable file named something similar to LI-7x00_win-8.x. Double click to launch the installer.

- Follow the Windows Installation wizard to install the application.

- Several individual applications will be installed, including the windows software, a file management application, and a file viewer application (fv7x00-1.x.x-install.exe).

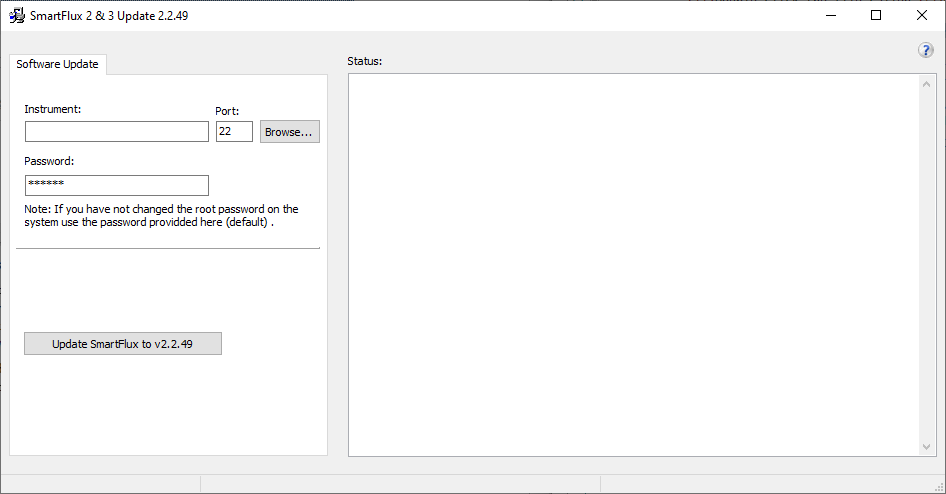

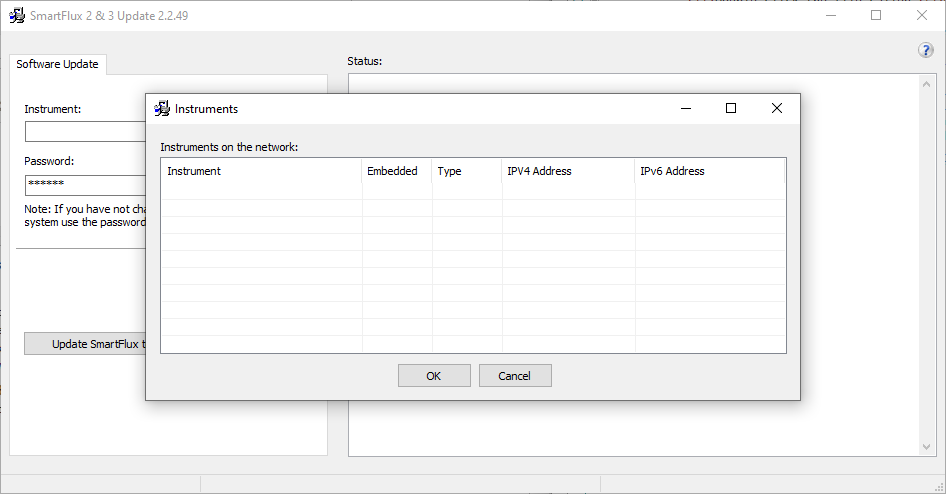

SmartFlux 3 System software update

To update the software:

- Save the SmartFlux software update package to your computer.

- It is a collection of files in a zipped folder. Extract the contents of the file.

- Double click the file called update7x00.exe.

- Click Browse to view systems. You can also enter SmartFlux IP address or hostname as the Instrument.

- You may need to allow the updater to pass through your computer firewall. Your computer firewall may prompt you if required. All SmartFlux 2 and 3 Systems connected to your network will be visible in the window.

- After selecting system or entering the IP address, click Update Firmware.

- The updater will load the new system files. This process takes about 30 seconds to a minute to complete the update. Do not power off the device while it is updating.