Printable PDF: Summer and Winter Settings

Instructions for summer and winter settings for the LI-7200 and LI-7500RS analyzers.

The LI-7200 and LI-7500A gas analyzers regulate the temperature of the chopper motor housing to ensure stable performance over the entire operating temperature range of -25 to +50 °C. The Settings tab of the LI-7200/LI-7500A Windows application software has an Advanced tab that provides options for selecting summer (30 °C) and winter (5 °C) settings for the chopper motor housing temperature. Set the chopper housing temperature under Settings > Advanced.

These settings are not directly related to the temperature requirements for the normal operation of the instrument, but are specified to reduce the effects of surface heating and power consumption under different ambient temperature regimes.

Surface heating can occur due to solar radiation load on an instrument and due to the heat produced by the instrument’s electronics. When there is a large differential between ambient temperature and the surface temperature of the instrument, heating results in a heat flux from the instrument surface, which will add to the expansion term in the WPL correction for open path analyzers used for eddy covariance measurements. When not accounted for, this heat flux can produce the appearance of a small artificial flux as an apparent CO2 uptake.

1‑1

Fc is the final CO2 flux, Fco is the uncorrected CO2 flux, μ is the ratio of molar masses of air to water, E is the evapotranspiration rate, H is the sensible heat flux, qc, ρd, ρv and ρ represents the mean CO2, dry air, water vapor and total air density respectively. Cp is the specific heat capacity of air, Ta is the air temperature and S is the heat flux due to surface heating.

In the older open path analyzer, the LI-7500, the chopper motor housing was kept at a constant 30 °C. Under cold conditions when then there is no real CO2 exchange, an artificial flux was observed, which was the result of sensor surface heating. The improved temperature setting control in the LI-7500A/LI-7200 enables the chopper to operate at the higher 30 °C and also at the lower 5 °C temperature setting. Thus when the environmental conditions are cooler (average temperatures below 5 °C), switching to the 5 °C setting reduces the effects of sensor heating due to the electronics and allows the instrument to operate with lower power consumption.

Enabling the 5 °C temperature setting for conditions with average temperatures greater than 5 °C is not recommended. Temperature regulation is achieved using a Peltier thermoelectric device. Providing a large temperature differential to cool against to will tax the peltier coolers and cause them to release more heat into the instrument’s optical path. This will also lead to higher power consumption.

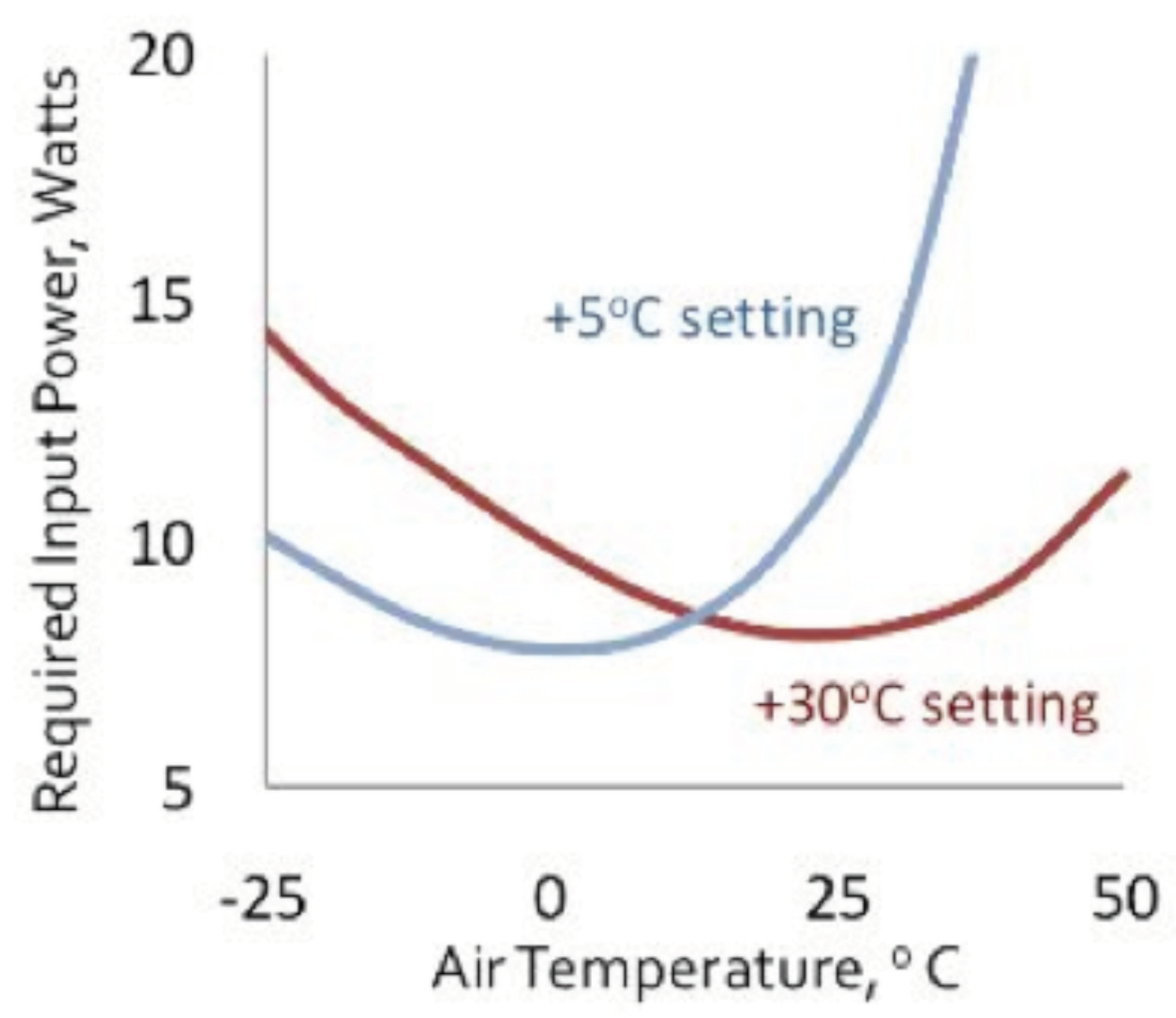

However leaving the chopper motor housing temperature at the 30 °C at average temperatures below 5 °C will not affect the normal operation of the instrument as heating is more efficient than cooling. But this will come at the cost of higher power consumption and make it necessary to apply additional density corrections to flux data collected with an open path instrument. The lower power consumption achieved by the 5 °C setting under colder ambient conditions is depicted in the figure on the following page.

A zero and a two point span must be performed on the instrument after changing between the winter and summer settings, as changing the temperature setting alters the filter properties of the instrument, and recalibration ensures that measurement specifications are achieved.

In the LI-7200 enclosed gas analyzer, the summer and winter settings are provided to reduce power consumption, rather than lowering sensor heating because fast mixing ratio measurements do not need the WPL correction, eliminating the need for a sensor heating correction term.