Collecting Data from the LI-7700 on a CR3000 or CR1000 Datalogger

In this application note we describe methods for collecting the Ethernet output from an LI-7700 with Campbell Scientific, Inc. dataloggers. The example CRBasic code given here should be applicable to both the CR1000 and CR3000 dataloggers.

Networking

A physical network connection is required from the LI-7700 to the datalogger to allow data collection. On the LI-7700, the network connection is accessed through an eight-pin Turck® connector on the bottom of the instrument. Network connections for the CR1000 and CR3000 are accessed through the instrument’s peripheral port using Campbell Scientific NL115 Ethernet and CompactFlash® Module.

The LI-7700 and datalogger can be connected directly together or via a local area network, but a direct connection is recommended. Direct connections eliminate the possibility of additional network traffic, which can slow data transfer and lead to missed data packets by the logger. However they are connected, the logger and the LI-7700 should be configured to operate with static IP addresses on the same subnet. An example network configuration is given in Table 1.

Within the datalogger program, the logger’s IP port must be enabled and configured to look for data packets sent from the LI-7700’s IP address. This is done using the TCPOpen command, which is given below:

Public tcpip_socket_status As Long

Dim socket As Long

BeginProg

TCPClose (101)

Scan (100,mSec,300,0)

…

NextScan

SlowSequence

Scan (5,Sec,3,0)

tcpip_socket_status = SerialInChk (socket)

If (tcpip_socket_status = -1) Then

socket = TCPOpen (“172.24.23.61”,7700,527)

EndIf

NextScanThe value 7700 in the TCPOpen command is the IP port where the LI-7700 is located. This is set at the factory for the instrument and will always be 7700. The IP address of this LI-7700 is 172.24.23.61 and is set by the user in the Manual Controls window of the instrument’s Windows® interface software. For the datalogger to talk to the LI-7700 the first three octets of their IP addresses should match (e.g. 172.24.23. nn), but the last octet must be unique to each device. The subnet mask and gateway should be set the same on both devices.

Data output and collection

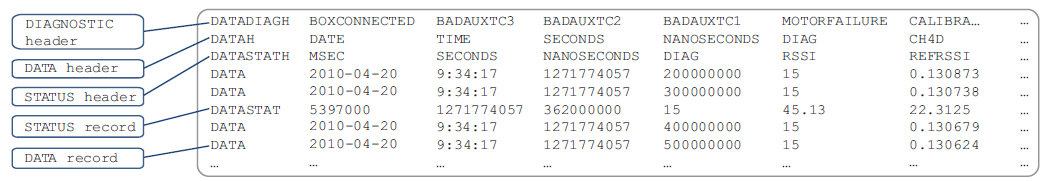

Data output from the LI-7700 is in the form of tab delimited ASCII text strings followed by a line feed (Figure 1). Upon connecting to the instrument, a set of headers containing labels for the variables included in each record type are sent from the LI-7700 to the datalogger. DATAH and DATASTATH list the variables included in the DATA and DATASTAT records, respectively. Any time the output rate is set to a value greater than zero, new DATA records will be output at the current output rate. DATASTAT is turned off by default in the LI-7700, but if needed it can be enabled by sending the command:

<licor><li7700><output><status>true</status></output></li7700></licor>followed by a line feed. The maximum output frequency for DATASTAT is fixed at 2Hz. When the instrument’s output rate is configured for greater than 2Hz, a DATASTAT record will not be output following each DATA record. Most variables included in the DATASTAT record are duplicated by flags in the diagnostic variable included in each DATA record, so it is generally not necessary to continuously collect DATASTAT. DATASTAT is most useful for troubleshooting purposes.

When the output rate is set to a value greater than zero, new DATA records are continuously output from the LI-7700. With the instrument configured this way, the datalogger can be set up to act like a terminal that captures each new DATA record, as in the example code given below:

Public LI7700_time(3) As Long

Public LI7700(22)

Public tcpip_socket_status As Long

Dim socket As Long

Dim DATA_string As String * 237

Dim NBR As Long

DataTable (Ethernet_data,TRUE,-1)

Sample (3,LI7700_time(1),Long)

Sample (19,LI7700(4),IEEE4)

EndTable

BeginProg

TCPClose (101)

Scan (10,mSec,300,0)

SerialInRecord (socket,DATA_string,&h44,0,&h0A,NBR,01)

SplitStr (LI7700_time(1),DATA_string,CHR(09),3,4)

SplitStr (LI7700(1),DATA_string,CHR(09),22,4)

If NBR>0 Then

CallTable Ethernet_data

EndIf

NextScan

SlowSequence

Scan (5,Sec,3,0)

tcpip_socket_status = SerialInChk (socket)

If (tcpip_socket_status = -1) Then

socket = TCPOpen (“172.24.23.61”,7700,527)

EndIf

NextScanIn this example, SerialInRecord looks for ASCII strings starting with “D” (&h44) to define when to start writing data to the variable DATA_string. SplitStr then parses out individual data points from DATA_string based the occurrence of tab charters (CHR(09)) in the ASCII string. The first three values included in the DATA record sent from the LI-7700 are 32 bit time stamps. These must be treated differently from the rest of the variables parsed from DATA_string, otherwise when the datalogger converts them from string to numeric variables they will be rounded to 24 bits by default.

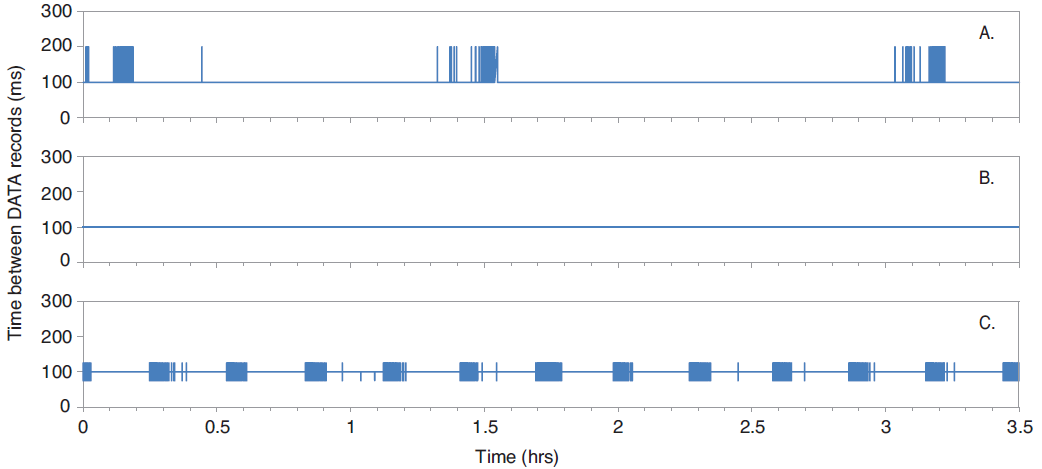

The scan interval used in this example, Scan (10,mSec,300,0), is much faster than the rate at which DATA records would normally be collected and the variables resulting from SplitStr are only written to the data table when a new record is received. Data from the LI-7700 should be collected this way because of timing asynchrony between the instrument and the datalogger. In a continuous data collection mode the timing between DATA records is controlled by the LI-7700, but the time between collecting DATA records is controlled by the scan interval of the logger. For a DATA record to be successfully collected by the logger, the record must be output within a certain window when the execution of a scan occurs. Since time keeping is handled separately by the two devices there is no mechanism ensuring this will happen. By using a scan interval that is much faster than the output rate of the LI-7700 the likelihood of missing a record is significantly reduced (Figure 3).

The LI-7700 also supports a polled mode, where the datalogger requests a new DATA record with each scan. When polled, the LI-7700 will return the next DATA record collected by the instrument at its base rate (40Hz) after the poll command is received. This will result in a baseline jitter in the data of 25 milliseconds (Figure 3C).

Polling is enabled by setting the output rate to zero and sending the command:

<licor><li7700><cmd><poll>true

</poll></cmd></li7700></licor>

followed by a line feed whenever a new DATA record is desired.

The SerialOutBlock instruction can be used to issue the string and should be placed in the main datalogger program following the SerialInRecord instruction, as given on the following page.

Public LI7700_time(3) As Long

Public LI7700(22)

Public tcpip_socket_status As Long

Dim socket As Long

Dim DATA_string As String * 237

Dim NBR As Long

DataTable (Ethernet_data,TRUE,-1)

DataInterval (0,0,Sec,100)

Sample (3,LI7700_time(1),Long)

Sample (19,LI7700(4),IEEE4)

EndTable

BeginProg

TCPClose (101)

Scan (100,mSec,300,0)

SerialInRecord (socket,DATA_string,&h44,0,&h0A,NBR,01)

SerialOutBlock(socket,”<licor><li7700><cmd><poll>true</poll></cmd></li7700></licor>”+CHR(10),61)

SplitStr (LI7700_time(1),DATA_string,CHR(09),3,4)

SplitStr (LI7700(1),DATA_string,CHR(09),22,4)

CallTable Ethernet_data

NextScan

SlowSequence

Scan (5,Sec,3,0)

tcpip_socket_status = SerialInChk (socket)

If (tcpip_socket_status = -1) Then

socket = TCPOpen (“172.24.23.61”,7700,527)

EndIf

NextScanAuxiliary sensor data

There are four single ended analog input channels and three thermocouple input channels available on the LI-7700. In applications where it is necessary to have auxiliary sensor data synchronized with the data from the LI-7700 (e.g. wind speed data in an eddy covariance application), the sensor should be connected via these inputs. This will compensate for the clock asynchrony between the datalogger and LI-7700, ensuring that the auxiliary sensor is sampled at the same rate as the LI-7700.

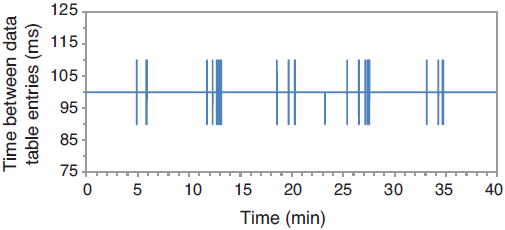

It is important to note that the sensor should be connected directly to the LI-7700, whether operating in polled mode where timing jitter is obvious between records, or when operating in continuous mode with conditional sampling even though there is no jitter between DATA records. This is because in continuous mode, there is an apparent drift in the time between when DATA records are written to the final storage table, which is equal to the scan interval. In the example used here, the datalogger’s time stamp shows a 10 ms jitter roughly every five minutes (Figure 3). Using the LI-7700 as the primary interface for the auxiliary sensor ensures this jitter does not affect data quality.

Note: If adding the LI-7700 to a flux station where carbon dioxide and water vapor are measured, it may be necessary to split the output from the sonic anemometer so that it can be sampled by both the datalogger directly and the LI-7700.

Appendix A

Example CRBasic program for unprompted data collection. The example code can be copied and pasted directly into CRBasic, and should compile correctly for both the CR1000 and CR3000.

PipeLineMode

Const Output_interval = 30 ‘Diagnostic data table output interval.

Const Buffer_Size = 527

Const NBE = 237 ‘Number of bytes expected

Public LI7700_time(3) As Long

Public LI7700(22)

Public diag_bits(16) As Boolean

Public tcp_close As Boolean

Public tcp_open As Boolean

Public tcpip_socket_status As Long

Alias LI7700_time(1) = milliseconds

Alias LI7700_time(2) = seconds

Alias LI7700_time(3) = nanoseconds

Alias LI7700(4) = Diagnostic

Alias LI7700(5) = CH4_density

Alias LI7700(6) = CH4_mole_fraction

Alias LI7700(7) = Temperature

Alias LI7700(8) = Pressure

Alias LI7700(9) = RSSI

Alias LI7700(10) = Drop_rate

Alias LI7700(11) = Aux(8)

Alias LI7700(19) = TC(3)

Alias LI7700(22) = DATA_checksum

Alias diag_bits(1) = box_connected

Alias diag_bits(2) = bad_aux_tc3

Alias diag_bits(3) = bad_aux_tc2

Alias diag_bits(4) = bad_aux_tc1

Alias diag_bits(5) = motor_failure

Alias diag_bits(6) = calibrating

Alias diag_bits(7) = bottom_heater_on

Alias diag_bits(8) = top_heater_on

Alias diag_bits(9) = pump_on

Alias diag_bits(10) = motor_spinning

Alias diag_bits(11) = block_tmpr_unregulated

Alias diag_bits(12) = laser_tmpr_unregulated

Alias diag_bits(13) = bad_tmpr

Alias diag_bits(14) = ref_unlocked

Alias diag_bits(15) = no_signal

Alias diag_bits(16) = not_ready

Units milliseconds = ms

Units seconds = s

Units nanoseconds = ns

Units CH4_density = mmol/m^3

Units CH4_mole_fraction = umol/mol

Units Temperature = C

Units Pressure = kPa

Units RSSI = %

Units Drop_rate = %

Units TC() = C

Dim socket As Long

Dim DATA_string As String * NBE

Dim NBR As Long ‘Number of bytes returned in DATA_string

Dim checksum_datalogger

Dim checksum_flag As Boolean

Dim diag_work As Long

Dim n

DataTable (Ethernet_data,TRUE,-1)

Sample (3,milliseconds,Long)

Sample (19,Diagnostic,IEEE4)

Sample (1,checksum_datalogger,IEEE4)

EndTable

DataTable (Diagnostic_flags,TRUE,-1)

DataInterval (0,Output_interval,Min,100)

FieldNames (“nnd_7700_Tot”)’No new data (sensor not connected or powered)

Totalize (1,n,IEEE4,NBR<>0 IMP checksum_flag)

FieldNames (“checksum_err_7700_TOT”)’Checksum error

Totalize (1,n,IEEE4,checksum_flag IMP NOT (box_connected))

FieldNames (“box_connected _TOT”)’LI-7550 connected or not

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bad_aux_tc3))

FieldNames (“bad_aux_tc3_TOT”)’Bad reading at TC3

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bad_aux_tc2))

FieldNames (“bad_aux_tc2_TOT”)’Bad reading at TC2

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bad_aux_tc1))

FieldNames (“bad_aux_tc1_TOT”)’Bad reading at TC1

Totalize (1,n,IEEE4,checksum_flag IMP NOT (motor_failure))

FieldNames (“motor_failure_TOT”)’Mirror spin motor failure

Totalize (1,n,IEEE4,checksum_flag IMP NOT (calibrating))

FieldNames (“calibrating_TOT”)’Calibration routine enabled

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bottom_heater_on))

FieldNames (“bottom_heater_on_TOT”)’Bottom mirror heater on

Totalize (1,n,IEEE4,checksum_flag IMP NOT (top_heater_on))

FieldNames (“top_heater_on_TOT”)’Top mirror heater on

Totalize (1,n,IEEE4,checksum_flag IMP NOT (pump_on))

FieldNames (“pump_on_TOT”)’Washer pump activated

Totalize (1,n,IEEE4,checksum_flag IMP NOT (motor_spinning))

FieldNames (“motor_spinning_TOT”)’Bottom mirror spinning

Totalize (1,n,IEEE4,checksum_flag IMP NOT (block_tmpr_unregulated))

FieldNames (“block_tmpr_unregulated_TOT”)’Block temp not at set point

Totalize (1,n,IEEE4,checksum_flag IMP NOT (laser_tmpr_unregulated)))

FieldNames (“laser_tmpr_unregulated_TOT”)’Laser temp not at set point

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bad_tmpr))

FieldNames (“bad_tmpr_TOT”)’Bad TC in optical path

Totalize (1,n,IEEE4,checksum_flag IMP NOT (ref_unlocked))

FieldNames (“ref_unlocked_TOT”)’Reference signal not line locked

Totalize (1,n,IEEE4,checksum_flag IMP NOT (no_signal))

FieldNames (“no_signal_TOT”)’No laser signal detected

Totalize (1,n,IEEE4,checksum_flag IMP NOT (not_ready))

FieldNames (“not_ready_TOT”)’LI-7700 not ready

EndTable

BeginProg

TCPClose (101)

n = 1

Scan (10,mSec,300,0)

SerialInRecord (socket,DATA_string,&h44,0,&h0A,NBR,01)

SplitStr (LI7700_time(1),DATA_string,CHR(09),3,4)

SplitStr (LI7700(1),DATA_string,CHR(09),22,4)

checksum_flag = (DATA_checksum EQV (CheckSum (“D”&DATA_string,7,NBR-2)))

checksum_datalogger = CheckSum (“D”&DATA_string,7,NBR-2)

‘Break up the Diagnostic into 16 separate bits.

If ( (NBR <> 0) AND (checksum_flag) ) Then

diag_work = Diagnostic

box_connected = diag_work AND &h0001

bad_aux_tc3 = diag_work AND &h0002

bad_aux_tc2 = diag_work AND &h0004

bad_aux_tc1 = diag_work AND &h0008

motor_failure = diag_work AND &h0010

calibrating = diag_work AND &h0020

bottom_heater_on = diag_work AND &h0040

top_heater_on = diag_work AND &h0080

pump_on = diag_work AND &h0100

motor_spinning = diag_work AND &h0200

block_tmpr_unregulated = diag_work AND &h0400

laser_tmpr_unregulated = diag_work AND &h0800

bad_tmpr = diag_work AND &h1000

ref_unlocked = diag_work AND &h2000

no_signal = diag_work AND &h4000

not_ready = diag_work AND &h8000

Else

Move (milliseconds,3,-99999,1)

Move (LI7700(1),21,NaN,1)

Move (diag_bits(1),16,TRUE,1)

EndIf

If NBR<>0 Then

CallTable Ethernet_data

EndIf

CallTable Diagnostic_flags

NextScan

SlowSequence

Scan (5,Sec,3,0)

tcpip_socket_status = SerialInChk (socket)

If ( tcp_close ) Then

tcp_close = FALSE

TCPClose (socket)

EndIf

If ( (tcpip_socket_status = -1) OR tcp_open) Then

tcp_open = FALSE

socket = TCPOpen (“172.24.23.61”,7700,Buffer_size)

EndIf

NextScanAppendix B

Example CRBasic program for polled data collection. The example code can be copied and pasted directly into CRBasic, and should compile correctly for both the CR1000 and CR3000.

PipeLineMode

‘Measurement Rate 5 Hz 10 Hz 20 Hz

Const Scan_interval = 100 ‘200 mSec 100 mSec 50 mSec

Const Output_interval = 30 ‘Diagnostic data table output interval.

Const Buffer_Size = 527

Const NBE = 237 ‘Number of bytes expected

Public LI7700_time(3) As Long

Public LI7700(22)

Public diag_bits(16) As Boolean

Public tcpip_socket_status As Long

Alias LI7700_time(1) = milliseconds

Alias LI7700_time(2) = seconds

Alias LI7700_time(3) = nanoseconds

Alias LI7700(4) = Diagnostic

Alias LI7700(5) = CH4_density

Alias LI7700(6) = CH4_mole_fraction

Alias LI7700(7) = Temperature

Alias LI7700(8) = Pressure

Alias LI7700(9) = RSSI

Alias LI7700(10) = Drop_rate

Alias LI7700(11) = Aux(8)

Alias LI7700(19) = TC(3)

Alias LI7700(22) = DATA_checksum

Alias diag_bits(1) = box_connected

Alias diag_bits(2) = bad_aux_tc3

Alias diag_bits(3) = bad_aux_tc2

Alias diag_bits(4) = bad_aux_tc1

Alias diag_bits(5) = motor_failure

Alias diag_bits(6) = calibrating

Alias diag_bits(7) = bottom_heater_on

Alias diag_bits(8) = top_heater_on

Alias diag_bits(9) = pump_on

Alias diag_bits(10) = motor_spinning

Alias diag_bits(11) = block_tmpr_unregulated

Alias diag_bits(12) = laser_tmpr_unregulated

Alias diag_bits(13) = bad_tmpr

Alias diag_bits(14) = ref_unlocked

Alias diag_bits(15) = no_signal

Alias diag_bits(16) = not_ready

Units milliseconds = ms

Units seconds = s

Units nanoseconds = ns

Units CH4_density = mmol/m^3

Units CH4_mole_fraction = umol/mol

Units Temperature = C

Units Pressure = kPa

Units RSSI = %

Units Drop_rate = %

Units TC() = C

Dim socket As Long

Dim DATA_string As String * NBE

Dim NBR As Long ‘Number of bytes returned in DATA_string

Dim checksum_datalogger

Dim checksum_flag As Boolean

Dim diag_work As Long

Dim n

DataTable (Ethernet_data,TRUE,-1)

DataInterval (0,0,Sec,100)

Sample (3,milliseconds,Long)

Sample (19,Diagnostic,IEEE4)

Sample (1,checksum_datalogger,IEEE4)

EndTable

DataTable (Diagnostic_flags,TRUE,-1)

DataInterval (0,Output_interval,Min,100)

FieldNames (“nnd_7700_Tot”)’No new data (sensor not connected or powered)

Totalize (1,n,IEEE4,NBR<>0 IMP checksum_flag)

FieldNames (“checksum_err_7700_TOT”)’Checksum error

Totalize (1,n,IEEE4,checksum_flag IMP NOT (box_connected))

FieldNames (“box_connected _TOT”)’LI-7550 connected or not

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bad_aux_tc3))

FieldNames (“bad_aux_tc3_TOT”)’Bad reading at TC3

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bad_aux_tc2))

FieldNames (“bad_aux_tc2_TOT”)’Bad reading at TC2

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bad_aux_tc1))

FieldNames (“bad_aux_tc1_TOT”)’Bad reading at TC1

Totalize (1,n,IEEE4,checksum_flag IMP NOT (motor_failure))

FieldNames (“motor_failure_TOT”)’Mirror spin motor failure

Totalize (1,n,IEEE4,checksum_flag IMP NOT (calibrating))

FieldNames (“calibrating_TOT”)’Calibration routine enabled

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bottom_heater_on))

FieldNames (“bottom_heater_on_TOT”)’Bottom mirror heater on

Totalize (1,n,IEEE4,checksum_flag IMP NOT (top_heater_on))

FieldNames (“top_heater_on_TOT”)’Top mirror heater on

Totalize (1,n,IEEE4,checksum_flag IMP NOT (pump_on))

FieldNames (“pump_on_TOT”)’Washer pump activated

Totalize (1,n,IEEE4,checksum_flag IMP NOT (motor_spinning))

FieldNames (“motor_spinning_TOT”)’Bottom mirror spinning

Totalize (1,n,IEEE4,checksum_flag IMP NOT (block_tmpr_unregulated))

FieldNames (“block_tmpr_unregulated_TOT”)’Block temp not at set point

Totalize (1,n,IEEE4,checksum_flag IMP NOT (laser_tmpr_unregulated)))

FieldNames (“laser_tmpr_unregulated_TOT”)’Laser temp not at set point

Totalize (1,n,IEEE4,checksum_flag IMP NOT (bad_tmpr))

FieldNames (“bad_tmpr_TOT”)’Bad TC in optical path

Totalize (1,n,IEEE4,checksum_flag IMP NOT (ref_unlocked))

FieldNames (“ref_unlocked_TOT”)’Reference signal not line locked

Totalize (1,n,IEEE4,checksum_flag IMP NOT (no_signal))

FieldNames (“no_signal_TOT”)’No laser signal detected

Totalize (1,n,IEEE4,checksum_flag IMP NOT (not_ready))

FieldNames (“not_ready_TOT”)’LI-7700 not ready

EndTable

BeginProg

TCPClose (101)

n = 1

Scan (Scan_interval,mSec,300,0)

SerialInRecord (socket,DATA_string,&h44,0,&h0A,NBR,01)

SerialOutBlock (socket,”<licor><li7700><cmd><poll>true</poll></cmd></li7700></licor>”+CHR(10),61)

SplitStr (LI7700_time(1),DATA_string,CHR(09),3,4)

SplitStr (LI7700(1),DATA_string,CHR(09),22,4)

checksum_flag = (DATA_checksum EQV (CheckSum (“D”&DATA_string,7,NBR-2)))

checksum_datalogger = CheckSum (“D”&DATA_string,7,NBR-2)

‘Break up the Diagnostic into 16 separate bits.

If ( (NBR <> 0) AND (checksum_flag) ) Then

diag_work = Diagnostic

box_connected = diag_work AND &h0001

bad_aux_tc3 = diag_work AND &h0002

bad_aux_tc2 = diag_work AND &h0004

bad_aux_tc1 = diag_work AND &h0008

motor_failure = diag_work AND &h0010

calibrating = diag_work AND &h0020

bottom_heater_on = diag_work AND &h0040

top_heater_on = diag_work AND &h0080

pump_on = diag_work AND &h0100

motor_spinning = diag_work AND &h0200

block_tmpr_unregulated = diag_work AND &h0400

laser_tmpr_unregulated = diag_work AND &h0800

bad_tmpr = diag_work AND &h1000

ref_unlocked = diag_work AND &h2000

no_signal = diag_work AND &h4000

not_ready = diag_work AND &h8000

Else

Move (milliseconds,3,-99999,1)

Move (LI7700(1),21,NaN,1)

Move (diag_bits(1),16,TRUE,1)

EndIf

CallTable Ethernet_data

CallTable Diagnostic_flags

NextScan

SlowSequence

Scan (5,Sec,3,0)

tcpip_socket_status = SerialInChk (socket)

If ( tcpip_socket_status = -1) Then

socket = TCPOpen (“172.24.23.61”,7700,Buffer_size)

EndIf

NextScan