Multi-Point sampling with the LI-7810 and LI-7815 Trace Gas Analyzers

Printable PDF: Multi-Point sampling with the LI-7810 and LI-7815 Trace Gas Analyzers

(7800_Note_Tall-Towers_19054.pdf)

Download this content as a pdf that can be saved to your computer or printed.

LI-COR LI-7810 CH4/CO2/H2O and LI-7815 CO2/H2O Trace Gas Analyzers are designed to be flexible, for use in a variety of different configurations and research applications. One frequent use is integration of the analyzers with a multi-point sampling system. These sampling systems can be used from research in a lab to long-term monitoring sites, where there is a need for frequent and automated calibration. A good example is a tall tower atmospheric monitoring site, an example of which is shown in Figure 1.

Here samples are collected from different heights on the tower, and the instrument is calibrated on a frequent basis in accordance with network protocols. The implemented system must be capable of selecting samples from the tower as well as a suite of calibration gases, either via a pre-programmed sequence or via direct, remote control.

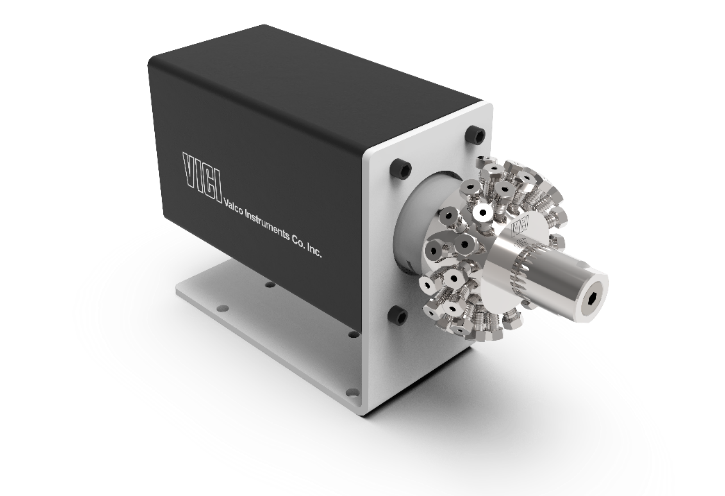

The option discussed here is the use of rotary selector valves, specifically those manufactured by VICI - https://vici.com/vval/vval_mpos.php - See Figure 2. VICI selector valves come in a variety of configurations, offering from 4 to 16 inlets, routed to a single outlet. In the dead-ended configuration, gas flows through the selected line only, while others are closed. In the flow-through configuration and with a vacuum pump connected down-stream, gas flows through all 4 to 16 inlets with the selected outlet directed to a single output for connection to the analyzer. The latter configuration is ideal where high variability in matrix composition is expected, or if ‘sticky’ components are present. Under these circumstances it is preferable to maintain continuous flow through all inlet lines, potentially improving response time when switching between sample inlets.

To meet stringent accuracy requirements specified for measurement network applications, multiple, expensive calibration gases, stored in high-pressure cylinders, are in daily use at monitoring sites. The use of these calibration gases, and the frequency with which cylinders must be changed is impacted significantly by the flow rate requirements of installed analytical instrumentation.

VICI Valve Control

VICI rotary valves, fitted with a Universal Electric Actuator, are supplied with a controller, shown in Figure 3. The controller has three buttons: Forward one outlet, Reverse one outlet, and Home (to position 1). This is the simplest approach for manual control.

Remote control and automated operation

If remote actuation, and/or an automated valve outlet sequence is required, there are several options available. In Option 1 we present a brief introduction to GCWerks. This software provides the most complete solution for remote, scheduled valve control, as well as instrument data acquisition, processing, and visualization. In Options 2, 3, and 4 we look at some less sophisticated solutions for basic remote valve control, some of which provide the facility to run automated, timed actuation sequences. In Option 5, we present a brief introduction to possible custom solutions requiring a degree of programming knowledge. Following descriptions of these 5 options we provide a worked example of what can be achieved with one of the less sophisticated solutions available, giving instructions how to configure a basic valve switching sequence using Option 3, VCom.

In all cases, the valve must be connected to either a networked laptop/PC at the measurement location, or directly to an Ethernet connection via an adapter We have successfully tested the Brainboxes Ethernet-to-Serial adapter (brainboxes.com/small-form-ethernet-to-serial). Details of this option are presented in Worked Example – Ethernet-to-RS-232 Adapter for Remote Operation. The VICI Universal Actuator has USB and RS-232 connection options. If the RS-232 option is used, an RS-232-to-USB adapter can be used to connect the VICI valve to a laptop/PC USB port (LI-COR part number 6400-27).

Option 1: GCWerks

GCWerks is now compatible with LI-COR LI-78xx instruments and is available for purchase. GCWerks manages instrument data acquisition, processing, and visualization, in addition to sophisticated instrument performance monitoring and diagnostics. It is the software of choice for a sizeable number of global sites for networks. Control of the VICI selector valve is fully integrated into the GCWerks software, allowing simple valve port selection as well as complete management of sample measurement and calibration protocols, with selected sample/valve port synchronized with other instrument data. GCWerks is capable of coordinating measurements from multiple analyzers at multiple remote sites, offering complete atmospheric measurement network management.

GCWerks connects to instruments at a remote site via a single Linux system, providing a secure point of access to remote instruments. Once installed, the software facilitates the easy handling of large quantities of data, with a fast graphical user interface allowing the review of years’ of data.

At the 2019 meeting of the American Geophysical Union (AGU), LI-COR presented a poster, co-authored by the developer of GCWerks, displaying data acquired and processed using the software. You can download the document here and see examples of valve control/sample selection, and resulting plots produced by the software:licor.app.boxenterprise.net/s/z3ukos1fnugdfxp2imwv2yu6mq423h3b

Contact GCWerks for further details: www.gcwerks.com.

Option 2: HyperTerminal

HyperTerminal has not been included in a Windows operating system since Windows XP. The developer of the original HyperTerminal, Hilgraeve, has continued to develop the software and it is now available for purchase for use with more recent Windows operating systems, including Windows 10.

HyperTerminal supports text-based communication through Telnet, SSH, Modem, and Serial port connections. The software receives and processes data through a terminal emulator that is designed to mimic different types of terminal systems. The terminal emulator processes control codes and decides where and how that data is displayed on the terminal screen, and allows control codes to be sent back to the system as needed.

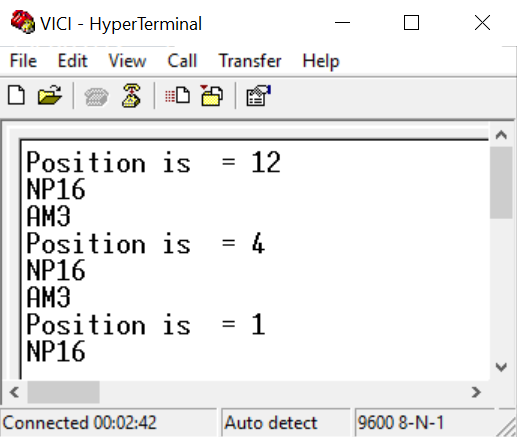

Instructions available in Technical Note 420-3 on the VICI web site - https://www.vici.com/support/tn/tn420-3.pdf - show how to connect to the valve actuator and to select valve ports using the command window. In the example shown in Figure 4, the ‘stat’ command has been used to verify valve port position following the ‘go(x)’ command, where (x) is the target valve port number. NP16 is the number of valve ports, in this case 16. AM is the actuator mode, in this case 3, multi position. A full list of commands is available in the VICI valve actuator manual - https://vici.com/support/manuals/universal-actuator.pdf.

Option 3: VCom

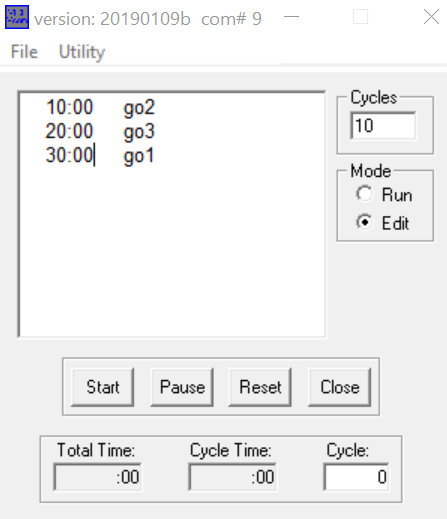

Once connected to the valve actuator, VICI’s VCom application can be used to send a sequence of text strings to the actuator at timed intervals. The number of cycles for the actuation sequence is user defined. Actuation sequences can be saved and recalled. The Vcom software is available from VICI on request, and the user manual is available for download on their web site - https://www.vici.com/support/tn/tn618.pdf.

Option 4: Diablo MPValve (Controller and Sequencer)

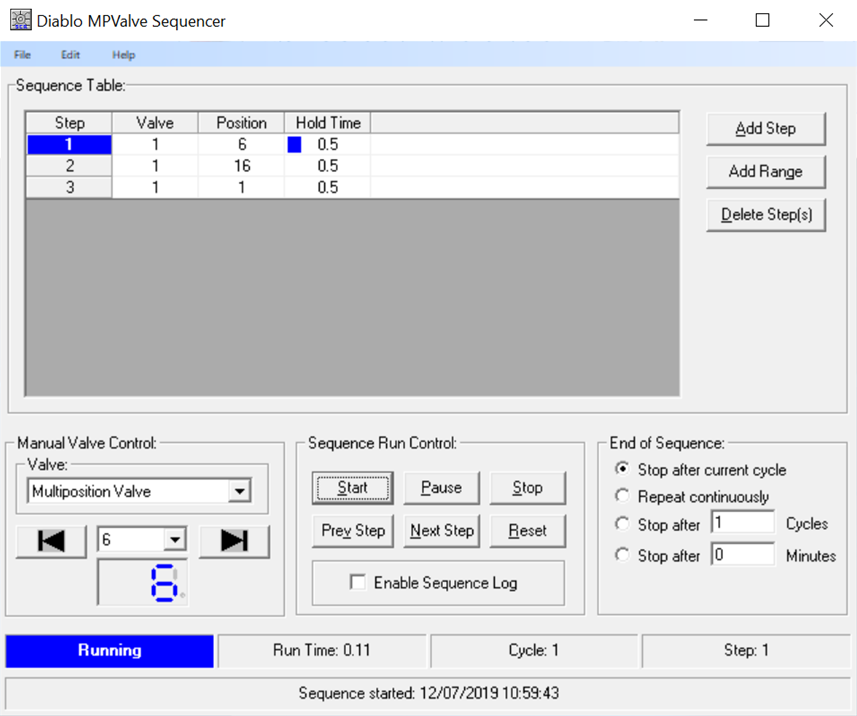

Diablo offers a user-friendly interface, along with useful valve sequencing features. The Controller software replicates features of the manual remote control, allowing increment/decrement of valve position. In the Sequencer software, sequence step parameters can be entered via the simple GUI, and steps repeat either indefinitely, after a defined number of cycles, or a defined time period. Current valve position is displayed within the GUI. Sequences can be saved for later use. Learn more by visiting https://diabloanalytical.com/products/software/mpvalve/.

Option 5: Custom solutions

With a low-cost computer, for example a Raspberry Pi, and a degree of electronics and programming knowledge, it would be possible to produce a custom solution with similar functionality to those described in Options 2, 3, and 4 above. In addition to effecting simple valve control, suitable software could also merge valve status information with data from LI-COR’s Trace Gas Analyzers.

A number of projects based on this concept are planned, and this document will be updated accordingly as further information becomes available.

Worked Example – VCom

As an example of what can be achieved with one of the less sophisticated solutions available, below is an example of how to configure a basic valve switching sequence using VCom. In this example a 16-port dead-ended VICI selector valve (model EUTA-SD16MWE) was connected to a LI-7810 analyzer. For the purpose of this simple test, all inlet ports of the VICI selector valve were sampling ambient air.

- Connect the VICI valve to a laptop or PC using the serial cable supplied. Connect to a USB port via a serial-to-USB adapter (LI-COR part number 6400-27).

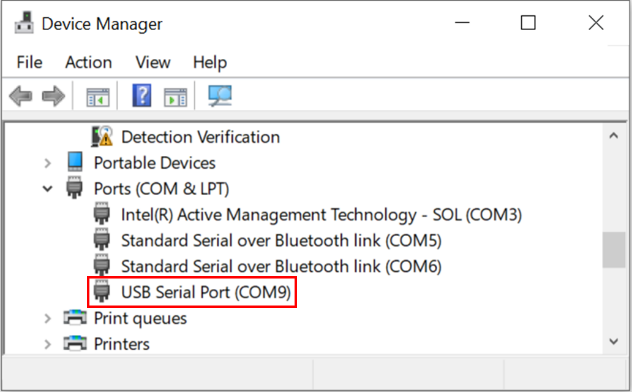

- Verify the COM port number.

- Open the Device Manager and expand Ports:

- USB Serial Port confirmed as COM9.

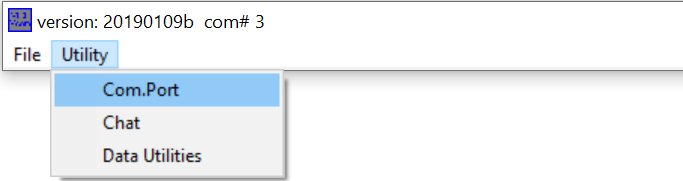

- Open Vcom software by running VCom V2.exe.

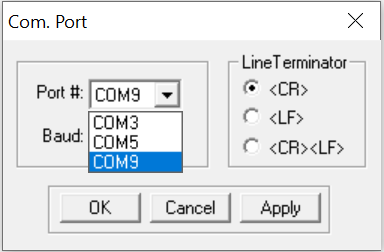

- Select the COM port.

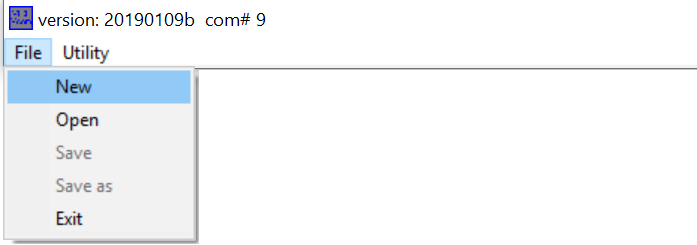

- Start a new file.

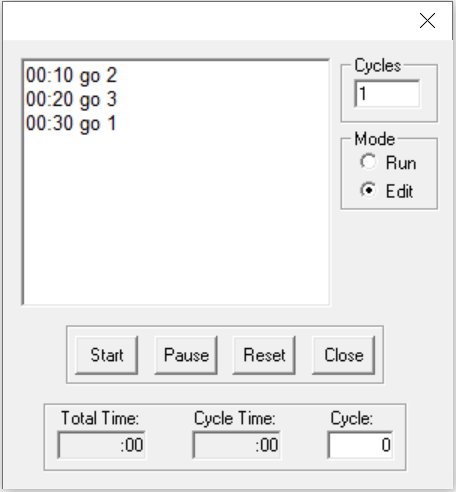

- Opens new sequence editor window.

- Enter inlet selection sequence.

- In Edit mode, enter details of the inlet selection sequence.

- In this example we instruct the valve to hold its current position (1) for 10 seconds before switching to position 2. The valve is held at this position for another 10 seconds before moving to position 3. After a further 10 seconds the valve will then return to position 1. The number of cycles is set to 1.

- The full list of commands can be found in the VCom instruction manual, available for download via VICI’s web site.

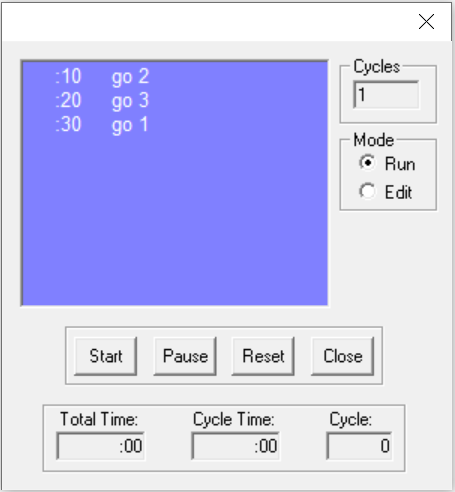

- Run valve inlet sequence.

- Select Run Mode and press Start to initiate valve inlet sequence.

- Save sequence method.

- Select File > Save as, navigate to selected folder and enter a file name. Save the file.

Worked Example – Ethernet-to-RS-232 Adapter for Remote Operation

VICI selector valves are supplied with one of three communications connection options: RS-232/485, USB, or BCD. To operate the valve remotely, the valve can be connected to a laptop or PC at the site and then controlled remotely by accessing the computer, or alternatively the valve can be connected directly to an Ethernet port via a suitable adapter. Here, we present an example of how such an adapter can be used to connect the VICI selector valve directly to a local network or internet, allowing remote control without the need for a local computer.

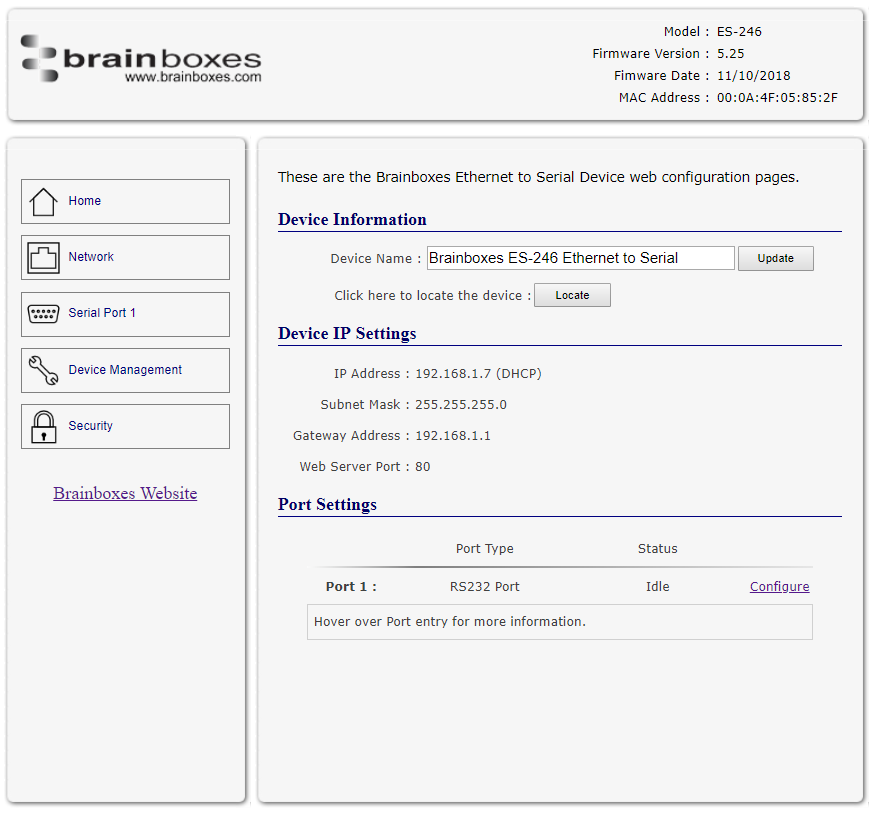

Brainboxes’ ES-246, and similar products from other vendors, allow RS-232 devices to connect directly to an Ethernet port connected to your local network, or over the internet: http://www.brainboxes.com/small-form-ethernet-to-serial.

Install Boost.LAN Manager software from disk or download from Brainboxes web site - http://www.brainboxes.com/software.

Download software for the ES series for the appropriate Windows Operating System. Windows 10 is used in this example.

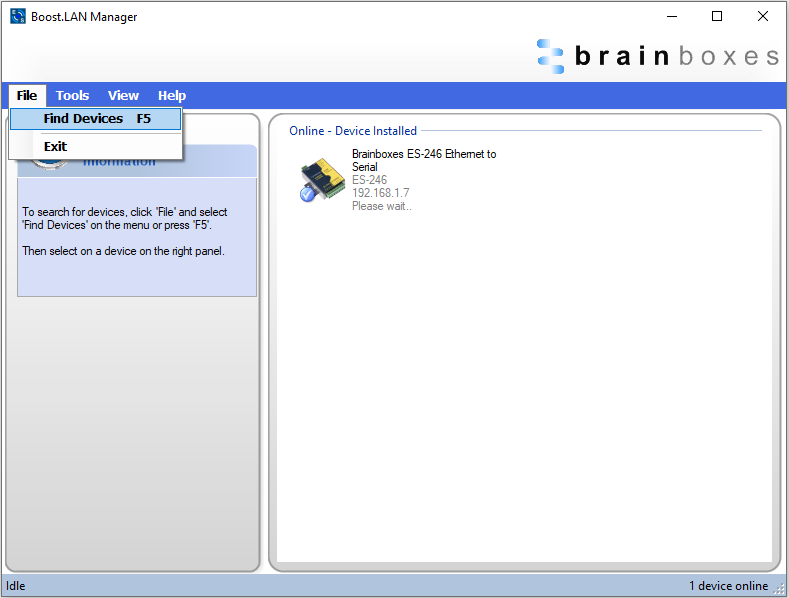

- Run Boost.LAN Manager.

- Select File > Find devices.

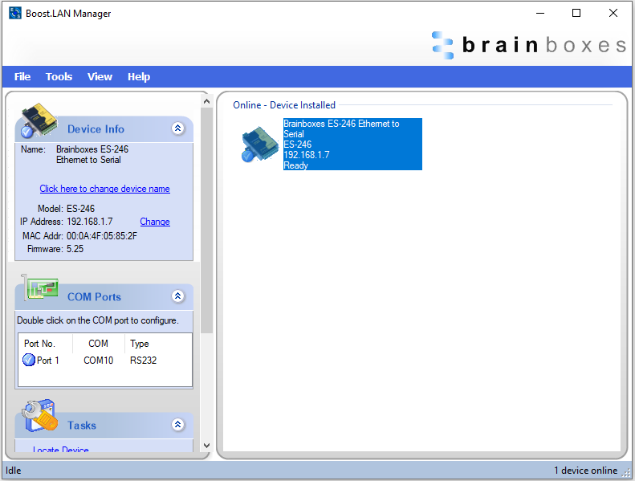

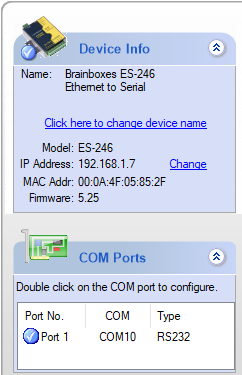

- Click on the device description in Online – Device Installed to confirm the COM Port number and IP address.

- To make a direct connection over a local network or internet connection, open an internet browser, and enter the IP address in the address bar. Press return to connect with the ES-246 adapter.

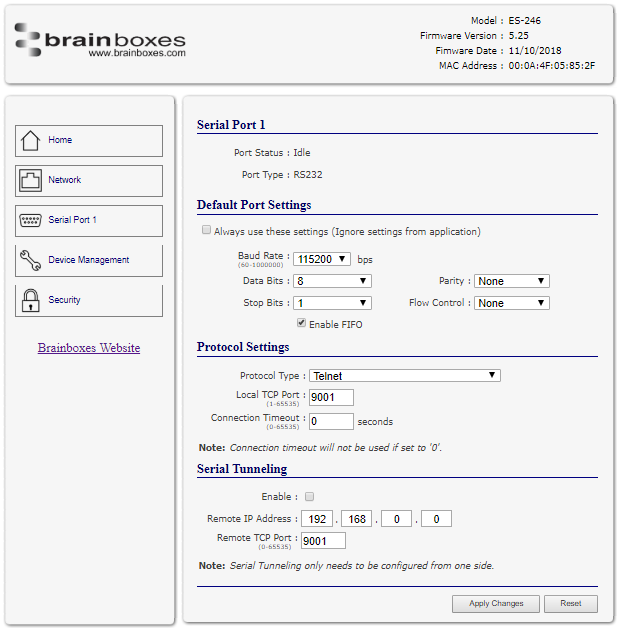

- Serial port parameters can be changed by selecting Serial Port 1 on the left menu

- The COM Port for the Brainboxes device can then be selected when connecting to the VICI selector valve via your software of choice; Telnet, VCom, Diablo MPValve, GCWerks, etc.