Printable PDF: 8100-102 Survey Chamber (10 cm) Vent Upgrade Kit

(8100_InstallGuide_Survey_Chamber_Vent_ACU103.pdf)

Instructions for installing the survey chamber vent upgrade kit.

Soil CO2 flux (FCO2) is a diffusion process that is primarily driven by the CO2 concentration gradient across the soil surface. Therefore, it is necessary for a chamber-based method to prevent any pressure differences between the chamber and the ambient air if measured FCO2 is to accurately represent the rate occurring naturally outside the chamber. To maintain the pressure equilibrium for our LI-8100 chambers, we initially used a vent consisting of two round, flat plates spaced 0.3 cm apart, and a tube connecting the vent to the chamber. The vent is located at the top of the chamber to avoid sensitivity to wind direction.

During field testing of the LI-8100, we found that with the existing vent design, soil CO2 flux could be overestimated under windy conditions. The reason for the overestimation was due to a phenomenon known as the Venturi effect. When the wind velocity between the two plates increases, static pressure in the chamber drops, pulling CO2-rich soil air into the chamber, leading to an overestimation of soil CO2 flux. So in terms of maintaining pressure balance, the current vent design is effective only under calm conditions, not under windy conditions.

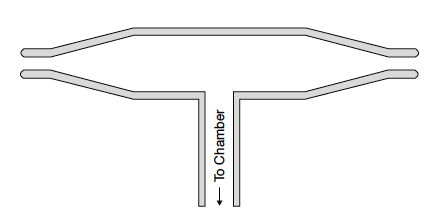

The new vent contained in this upgrade kit allows the LI-8100 to overcome the problem of potential overestimation in soil CO2 flux rates. The new vent has a tapered cross section as shown in Figure 1‑1. Conservation of mass requires that the average air flow rate drops in proportion as the vent cross section increases. By slowing down the wind velocity within the vent to essentially the same velocity as that at the soil surface, the Venturi effect can be avoided.

During field testing of this new vent design, we found that the chamber pressure always closely followed the ambient pressure under both calm and windy conditions. Soil CO2 flux measurements made with chambers equipped with this new vent design show that the overestimation of soil CO2 flux is eliminated.

For more detailed information, please review the poster entitled The Impact of Pressure Perturbation on Chamber-Based Soil CO2 Efflux Measurement. An electronic version of this poster is available for download from the LI-COR website at http://www.licor.com/soilflux; click on the Bibliography link. Please contact LI-COR with any questions you have.

Installation Instructions:

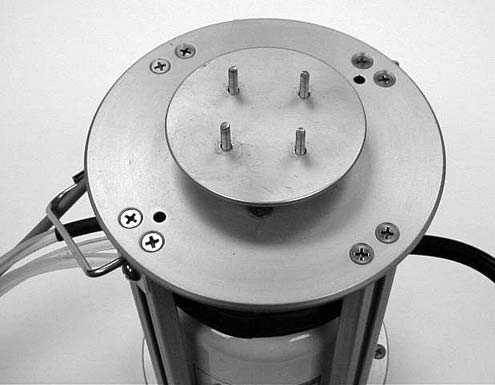

- Remove the four thumb nuts at top of existing vent assembly.

- With plastic vent tube still in place, pull top plate of vent assembly up and remove from four screws.

- Use a 5/16” wrench or socket (or pliers) to remove the four nut/washers from vent assembly. These nuts/ washers will not be used again.

- Remove bottom vent plate.

- Use a 1/4” wrench to remove the four spacers from vertical screws. These spacers will not be used again.

- Install new vent base plate over four vertical screws. The base plate does not have a vent hole in the center.

- Install four star washers on to vertical screws.

- Thread four spacers supplied with this kit on to screws – these will come to rest on top of the star washers. Tighten with 1/4” wrench. (Note that the spacers supplied with this kit are longer than the spacers removed from the old vent assembly.)

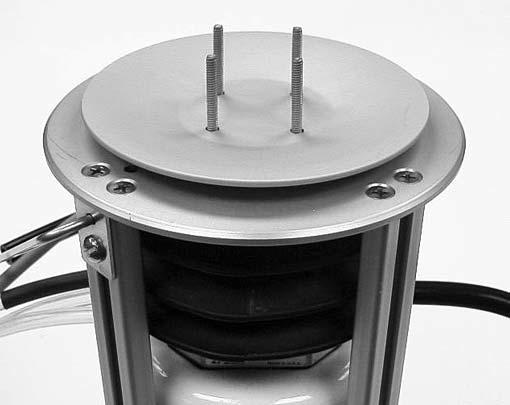

- Unthread top of old vent assembly from 90 degree plastic fitting by turning counterclockwise.

- Thread new vent plate on to plastic fitting by turning clockwise. Hand-tighten. A spare 90 degree fitting has been supplied, should the threads become stripped.

- Place new vent top plate over four vertical screws. The vent plate will come to rest on top of spacers.

- Install four thumb nuts on top of vent plate to secure vent assembly. Hand-tighten.