Getting Started Tutorial

The following section briefly covers the basic steps you might follow to set up the LI-820 to collect and record data. Many of these steps are described in greater detail throughout this manual.

- Install the 820-500 PC Communications Software.

- This software is used to set the zero and span of the LI-820 and to set up data communication and data transfer parameters. Installation instructions can be found in Section 3, Installing the Software on Your Computer.

- Determine your jumper settings for high and low alarm output, if required.

- There are 2 jumpers inside the LI-820 case (on the main circuit board) which toggle the high and low alarm output between 0-5V (TTL levels) and an open drain condition (see Section 2, Alarms).

- The default jumper positions are set for 0-5V output for both high and low alarms. This alarm configuration is suitable for logic devices such as dataloggers. To use the high and/or low alarms to operate a relay switch, the jumpers should be reconfigured for open drain output. See Section 2, Alarms, for a description of how to change the alarm jumper settings.

- If the default jumper positions are suitable for your application, or if you do not intend to use the alarms, proceed to Step 3.

- Connect a power source to the LI-820.

- The LI-820 requires an input voltage of 12-30 VDC. The power supply must be able to source a maximum current drain of 1.2A (at 12 VDC). After the instrument has warmed up it will draw about 0.3A (at 12 VDC) with the heaters on. Bare wire leads are connected to the terminal strip at positions 1 and 2. Connect the positive lead to position #1 (12-30VDC), and the negative lead to position #2 (GND).

- NOTE: Pull straight out on the terminal strip to remove it; this can make it easier to connect the wires.

- Connect the RS-232 cable.

- Connect one end of the serial cable to the 9-pin Serial I/O port on the LI-820 front panel, and the other end to a serial port on your computer. If you want to interface to a device with a 25- pin serial port, a 9-pin to 25-pin adapter must be used; a gender changer may also be required in some cases. Tighten the two screws on the ends of the serial cable. If your computer does not have a serial port, you can use the 6400-27 Serial-to-USB Adapter included to connect the serial cable to a USB port on your computer. The Adapter does not convert the RS-232 serial connection into a USB connection. It simply allows the USB port to receive data via a standard RS-232 serial connection.

- Connect other output device(s) if desired.

- Output devices such as dataloggers and relay switches for high and low alarms are connected via the terminal strip. A complete description of the terminals can be found in Section 3, Using the Terminal Strip.

- Connect an air pump and external power source.

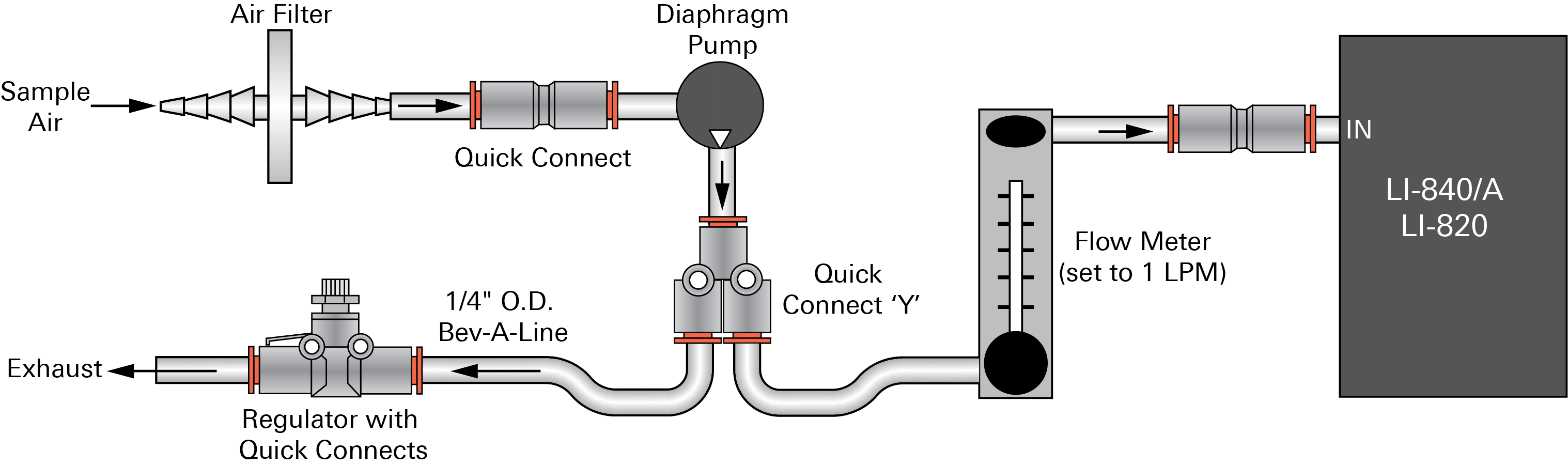

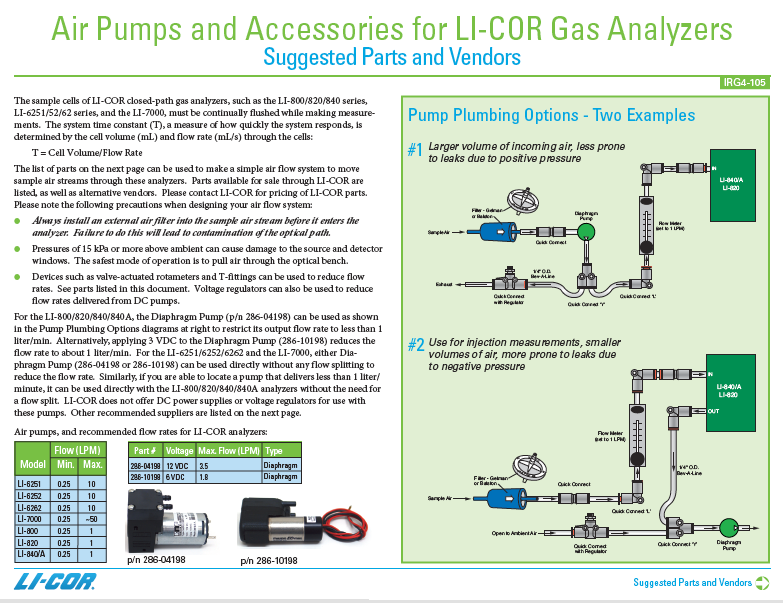

- The LI-820 sample cell must be continually flushed while making measurements, which requires an external air pump that supplies a flow rate of between 0.25 and 1.0 liters per minute. LI-COR offers a Diaphragm Pump under part number 286-04198 that is suitable for use with the LI-820. One pump plumbing option is shown below.

- NOTE: More information about plumbing options and parts available from LI-COR can be found in an application note, which can be viewed here.

- Hook up the input air stream and external filter.

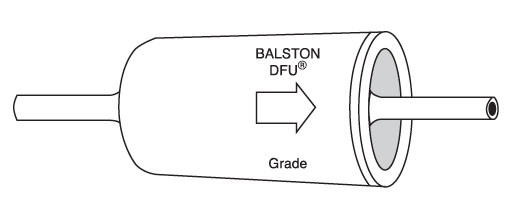

- Remove the nut from the FLOW IN fitting and connect a short (12" or so) piece of Bev-a-line tubing (in the spares kit). Tighten the nut. Place a Balston filter (also in the spares kit) in the sample airstream before it enters the FLOW IN port on the LI-820.

- IMPORTANT: Always install the external air filter before operating the LI-820. Insert filter into the input airstream before it enters the LI-820. Failure to do this will lead to contamination of the optical path.

- There are some quick connect fittings in the spare parts kit that can be used on either side of the Balston filter to aid in changing the filter out. Press on the red part of the fitting to release the tubing.

- When using the LI-820 for applications where sample air is particularly dirty, you may consider stacking two filters in series. For maintenance, replace the filter furthest upstream from the analyzer with the filter closest to the analyzer and replace the filter closest to the analyzer with a new filter.

- Note that the maximum flow rate through the LI-820 is approximately 1 liter/minute.

- Figure 1‑1. Install the new filter(s) with the arrow facing the FLOW IN port.

- The air inlet and outlet ports should be covered with the dust caps provided or attached to an air line when the instrument is not in use. This will prevent dust from entering the instrument downstream from the filters where it can enter the optical path. Replacement Balston filters can be obtained from LI-COR (part #300-01961).

- Start the 820-500 PC Communications Software.

- Click on the program icon to start the 820-500 program. The 820-500 Main window appears. Select Connect from the File menu. Choose the serial port to which the LI-820 is connected, and the data output interval. Select the COM port and the data output interval, if desired, and click the Connect button. If the analyzer is connected properly, data will appear in the main window.

- Configure the analyzer.

- Select Settings from the View menu. The Settings window appears. Choose a value for signal averaging (the Filter field), between 0 and 20 seconds. Set values for high and low alarms and corresponding dead bands, if desired. See Section 2 for a complete description of the alarms. If you are using an output device to collect data, choose the value to be output at DAC 1 and/or DAC 2. Make sure the Heater and Pressure Compensation buttons are enabled (checked), and click OK.

- Set the analyzer zero.

- Connect a dry, CO2-free gas to the input air stream. Select Calibration from the View menu. Click on Zero. After about a minute, a message will appear that indicates the IRGA is zeroed.

- Set the analyzer span.

- Connect your span gas to the input air stream. Enter the value of the span gas. Click on Span. After a few minutes, a message will appear indicating the span calibration is completed. Click Close.

- Set up the logging parameters.

- Select Options from the Logging menu. Choose the File Headings to be output with the data, the values to be logged, the field delimiter, and log frequency. Click OK. Choose Start from the Logging menu. Enter a file name for the data file. Click Save.

- Set up the charting parameters, if desired.

- Select Charting from the View menu. Enter the Y-Axis min and max values, X-Axis max, and time units to be displayed on the plot. Click Start to begin recording data. A graph with data will appear in the window and data will be logged to the file designated in Step 12 above.

- Choose Stop from the Logging menu to close the data file and stop recording when you are done collecting data.