Maintenance

Cleaning the Optical Bench

- Turn the LI-820 off. Remove the six screws on the LI-820 top panel and remove the cover. Note that these screws are not molded into the case and may fall out.

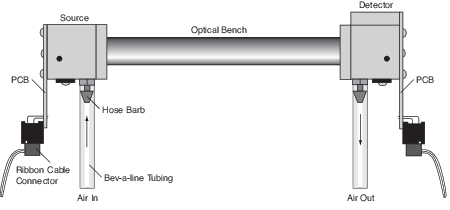

- Unscrew the tube retaining nuts on the inner air port fittings. Remove the tubing from both air ports. Leave the tubing connected to the source and detector housings.

- There are ribbon cables connected to the circuit boards on the source and detector housings. Pull straight out on the connector that is attached to each ribbon cable. The optical bench can now be removed from the foam casing.

-

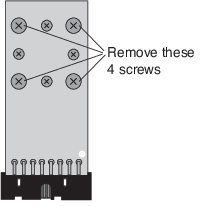

- There are four screws on the source and detector circuit boards that must be removed. Remove the four screws in the corners of the boards (they are slightly larger than the other four screws). Do not remove the remaining four screws.

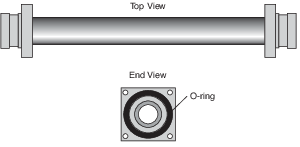

- The source and detector housings (with attached circuit boards) can now be removed. The bench will appear as shown below. It is a good practice to replace the O-rings when cleaning or replacing the optical path.

- There are a number of swabs in the spare parts kit (see at left). Dip one end of the swab into a 50:50 ethanol/water solution and carefully swab both ends of the optical bench, until there is no more visible residue. A mild solution of dish washing type soap and water will also work. Do not use abrasive cleansers, as they can irreparably damage the gold plating on the optical bench.

- Use a reflector swab and carefully swab the gold-plated concave surface of the source housing, if necessary.

- If you need to clean out the hose barbs and/or replace the tubing connected to the source and detector housings, use a small pair of diagonal cutters to remove the tubing from the hose barbs. Use the cutters to pinch the tubing parallel to the hose barb axis, and then pivot the cutters over the hose barb tip; the tubing will pull off of the hose barb. Be very careful not to cut the tubing or scratch the hose barb with the cutters, as subsequent tubing connections may leak.

- Let the optical bench dry. Re-assemble the bench, making sure the O-rings are in place on both ends of the bench. Note that the orientation of the cylinder is not important; either end can be inserted into the source or detector housing.

- Re-assemble the LI-820 case. Make sure that the foam insulation on the inside top cover is positioned over the optical bench; it is required for thermal stability.

- Perform zero and span calibrations as described in Section 3, Calibration Window.

Changing the Fuse

The LI-820 power supply is protected by a 2A 250V, 5 x 20 mm fast-blow type fuse located inside the case. If the battery fails to power the LI-820, and will not light the Power LED on the top panel, check to see if the fuse has blown.

To check the fuse, remove the six screws on the top of the LI-820. The fuse is located on the main circuit board, near the Flow In port.

Replacement fuses (part# 439-03952, in the spares kit) plug into the fuse holder; no soldering is required. Replace the fuse and reassemble the LI-820 case.

Storing the LI-820

The LI-820 can be stored in non-condensing conditions, but if it is exposed to high humidity or moderate humidity for a long period of time while it is powered off, the humidity can temporarily affect measurements. You can identify this issue by observing unexpected drift that stabilizes after several days of operation, an offset in measurements, or unresponsiveness. If your instrument exhibits these characteristics, verify the issue by comparing raw detector outputs in data that was collected before and after storage. If you don't have these data, contact LI-COR and we will provide the calibration data set for your instrument. In the PC interface software, click View > Diagnostics and observe the values for Raw CO2 Reference. If these values are lower than the original values, power on the instrument and let it run (with the heaters on) for several hours to several days. If the instrument has not fully recovered after several days, you may need to disassemble the optical bench and heat the detector in an oven at 65 °C (150 °F) for several hours. Reassemble the instrument and check the measurements.