Recomputing observations

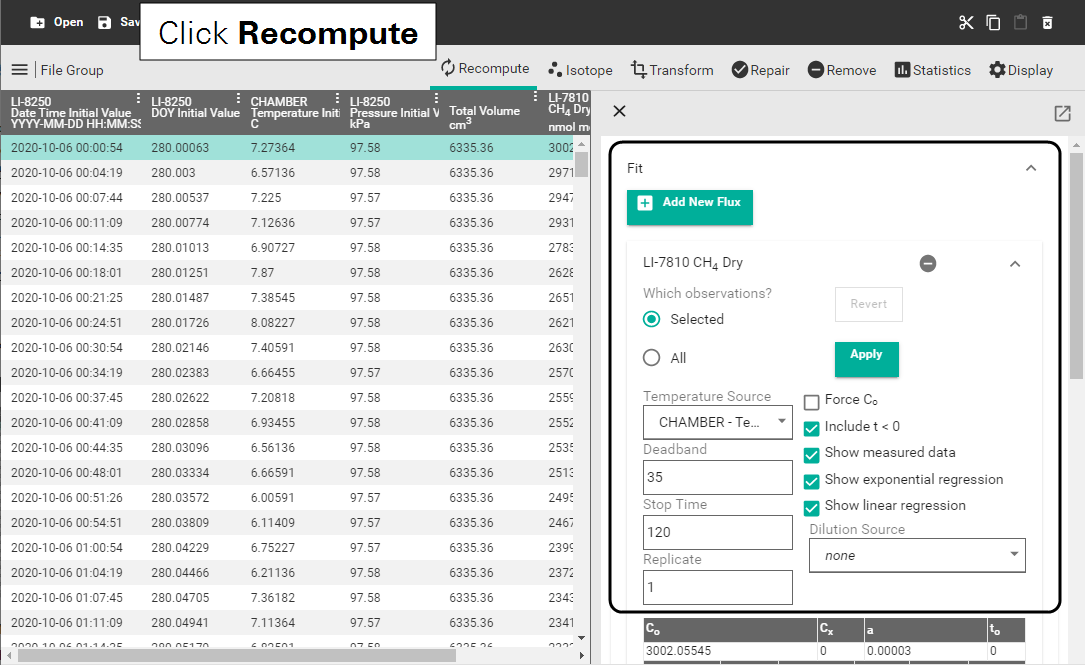

The Recompute settings allow you to use revised parameters, such as deadband, stop time, or system volume, in your flux calculations and includes tools for optimization. Any adjustments automatically recompute the flux in real time.

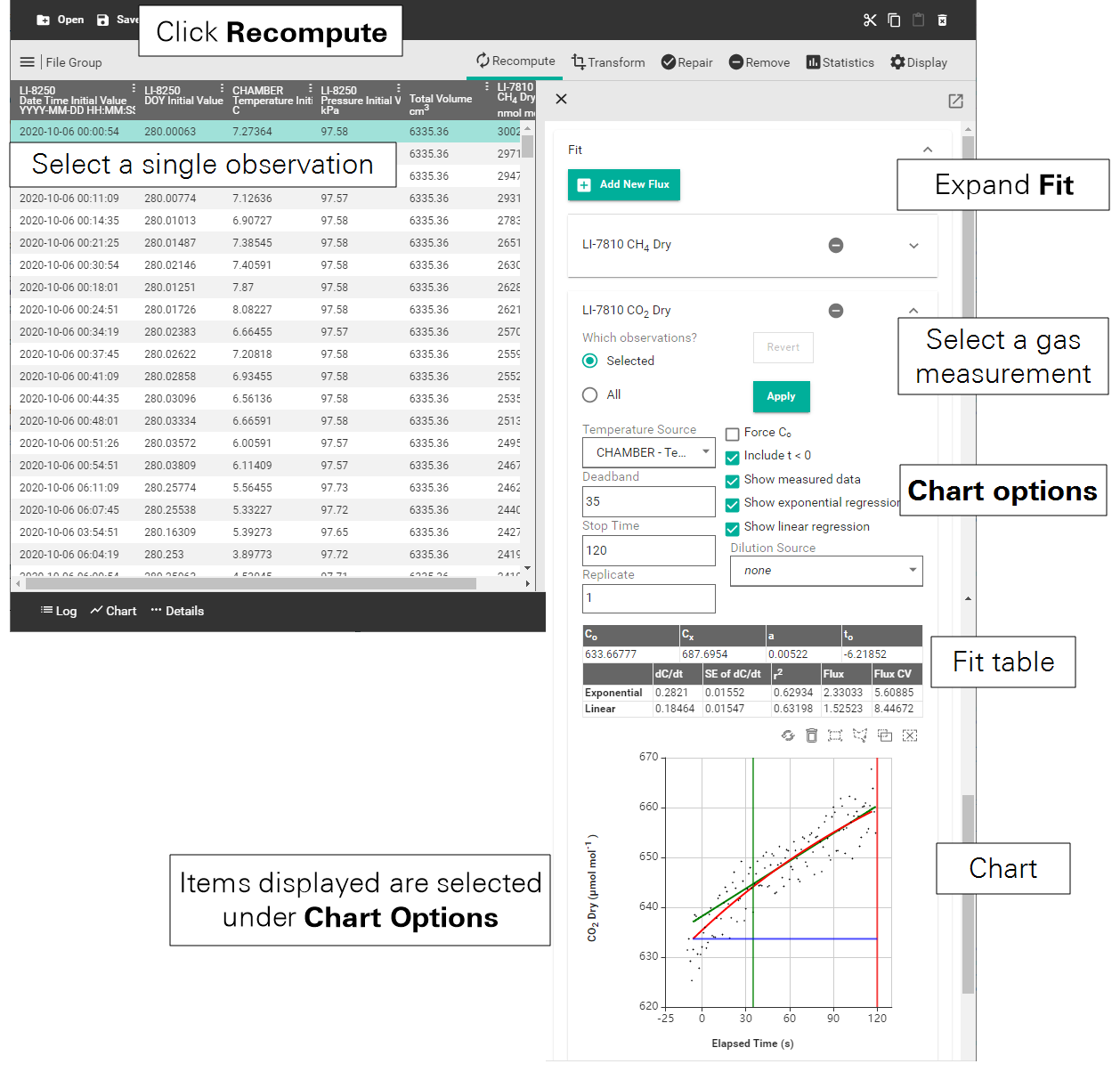

Note: When Which Observations is set to All or Selected and more than one is selected, no graph is displayed under Fit and Guidance is not available. Select a single observation to view the graph. If no observations are selected, any changes made in Recompute will be automatically applied to all observations.

Exploring the fit

Fit lets you change the variables used in flux calculations and observe the differences between exponential or linear fit.

Using the fit tools

- Choose whether you would like to use one of the existing fluxes or to Add New Flux.

- Add New Flux allows you to choose a new flux gas from a list of all gases measured by the device.

- Select the device and gas flux you will be recomputing.

- Select the observations you would like to work with.

- Selected refers to observations that you have selected in the Summary view. You can tell which observations you have selected, as they will be highlighted in the Summary view. You can select observations individually by clicking on them, or you can use Ctrl + click to select multiple individual observations or Shift + click to select all observations in a range.

- Update one of the variables.

- Deadband and Stop Time are common changes. The options are:

-

- Temperature Source allows you to change the source of the temperature measurement used in the flux calculation.

- Deadband is the period from complete chamber closing until steady mixing is achieved and the measurement begins. This is usually about 10 to 30 seconds but can vary and should be optimized using the Start Analysis tool (see Guidance with deadband analysis).

- Stop Time is the length of data used for the flux computation after the deadband. This can vary based on site conditions and should be optimized using the Stop Analysis tool (see Guidance with stop time analysis).

- Dilution Source lets you define the instrument that provided the water vapor measurement used in the dilution correction.

- Click Apply.

- To undo any changes you have made and return to the default settings click Revert. Revert only works on Selected observations. Any changes made to All observations cannot be undone using Revert.

Working with single observations

If you are working with a single observation, additional features, including a fit table and chart, are available.

Chart Options appear when you have a single observation selected. The information displayed on the chart depends on the number of observations selected.

- Force C0 allows you to force the initial gas concentration to whatever value you want using the blue line on the chart. Usually, C0 (the starting value) is determined from the initial value. You can manually override this by checking this box and then clicking and dragging the blue line to your chosen concentration.

- Include t < 0 updates the chart to include regressions and any data points collected prior to the chamber fully closing.

- Show measured data displays the measured data points for an observation.

- Show exponential regression plots the concentration against time and exponential fit.

- Show linear regression plots the concentration against time and linear fit.

The chart gives a visual representation of the flux for a specific observation. You can adjust the deadband (green line), stop time (red line), and C0 (blue line if you have checked Force C0) by clicking and dragging them to a new location. When you release the mouse button, the data are fit linearly and exponentially with the results shown in the fit table above the chart.

The Fit table provides calculations for a number of different variables.

| Variable | Definition |

|---|---|

| C0 | Initial dilution-corrected gas measurement |

| Cx | Asymptote parameter from exponential fit |

| a | Rate constant exponential coefficient |

| t0 | Time zero |

| dC/dt | Initial rate of change in dilution-corrected gas mole fraction |

| SE of dC/dt | Standard error of dC/dt for the fit |

| r2 | r2 value for the fit |

| Flux | Calculated flux |

| Flux CV | Coefficient of variation of the fit for the flux |

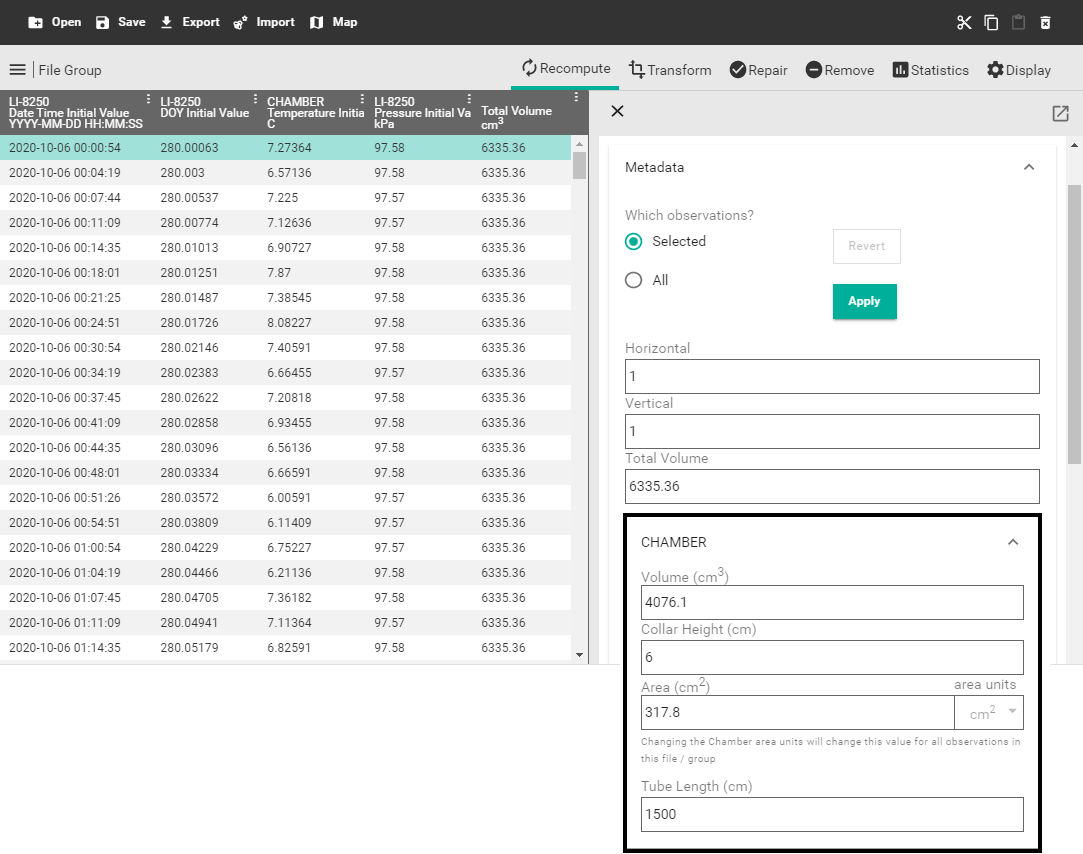

Metadata

Metadata allows you to update the volume or measurements of various components to ensure you have the correct Total Volume used to calculate your soil gas fluxes. The Total Volume field itself cannot be changed by the user but must be changed by updating a device component.

To use the Metadata tool:

- Select the observations you would like to update a measurement for.

- Choose one of the device drop-downs.

- Update one of the components, such as Collar Height, with the new measurement.

- Update any additional variables as needed.

- Click Apply.

The Total Volume will update using the new measurement data for all flux calculations on the chosen observation(s). The Revert button will return all Metadata component measurements to their original settings.

Note: The Area (cm2) field under CHAMBER includes a drop-down for area units. This drop-down allows you to change between area- and mass-based fluxes. Changing between area- or mass-based fluxes will affect the entire dataset as you may only apply a single flux type to a File Group.