Avoiding water ingress with the LI‑78xx Trace Gas Analyzers

Printable PDF: Avoiding water ingress with the LI‑78xx Trace Gas Analyzers

(78xx_Avoiding-Water-Ingress_19356.pdf)

Download this content as a pdf that can be saved to your computer or printed.

The high sensitivity delivered by LI-COR Trace Gas Analyzers results from use of a high-finesse optical cavity, allowing thousands of reflections for each measurement, folding an effective path length of kilometers into a cell just a few centimeters in length. The mirrors used to build the cavity have a reflectivity of over 99.999%. Although the cavity is well protected, maintenance of this reflectivity during long term operation of the analyzer is essential and it is vital that contamination of the mirror surfaces is prevented. This is true for all laser-based instruments that employ high finesse optical cavities, such as those based on cavity ring-down spectroscopy (CRDS) and off axis integrated cavity output spectroscopy (OA-ICOS).

Mirrors in the LI-78xx series analyzers are protected from particulate contamination via filters immediately upstream and downstream of the cavity. These filters are inaccessible by the user. Additional protection is afforded by a user-replaceable filter located immediately downstream of the analyzer gas inlet. In addition to particulate matter, the mirrors must also be protected from condensable liquids, including water.

The analyzers are designed to operate in humid conditions, with the cavity and other critical optical components located in a temperature-controlled enclosure providing an operating temperature of 55 °C. This elevated temperature prevents condensation of water in the cavity during normal measurement mode. During shutdown, if the cavity is allowed to cool while containing humid air, there would be a danger of condensation. To prevent this scenario, before power is shut off and the cavity begins to cool, inlet air is automatically diverted through the internal silica gel drying column and the cavity is purged to remove residual humidity.

While the analyzers are designed to prevent condensing water from contaminating mirrors in the optical cavity, under certain operating conditions, for example working on, or in the vicinity of a body of water, there is a risk of liquid water ingress directly into the instrument. Such an event dramatically increases the risk of contamination and the need for significant repair and associated down time. If you intend to operate your LI-78xx Trace Gas Analyzer in conditions that pose an increased risk of water ingress, there are steps you can take to reduce this risk and operate the analyzers more safely.

- In software version 2.0.21 and higher, we added support for automatically disabling the pump in response to a sudden pressure drop.

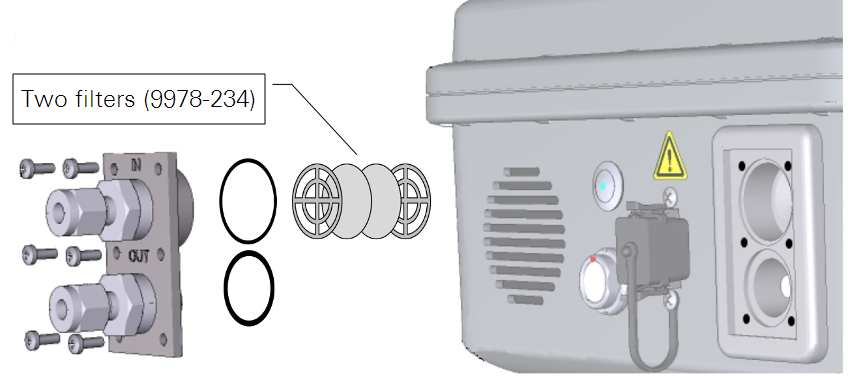

- An additional 0.2 µm filter should be used on the inlet. These 0.2 µm filters are fitted as standard to all new instruments. If your instrument is currently running a version of the software earlier than 2.0.21, please download and install the latest version, available via the LI-COR support web page - licor.com/support/home.html. We also suggest checking your inlet filters to ensure you are using two, 0.2 µm filters, as shown in the Figure 1.

- External filters are available that allow air flow but prevent the flow of liquid water, for example the Entegris Waferguard GT-Plus hydrophobic fluoropolymer PTFE filter - https://www.entegris.com/content/dam/shared-product-assets/wafergard-shared/datasheet-wafergard-gt-plus-and-gtl-in-line-5013.pdf.

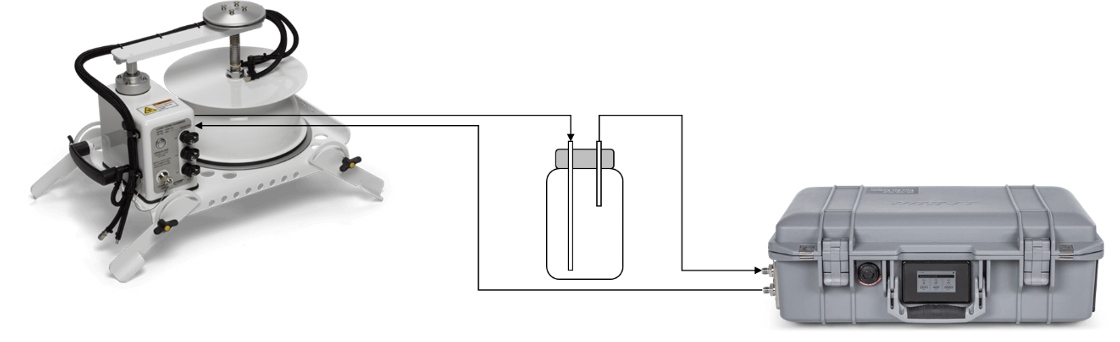

- Used in conjunction with the software update and installation of two 0.2 µm filters as described in (1), this provides additional protection should the inlet be exposed to liquid water. Such filters are an expensive consumable item and so an additional, lower cost user-replaceable filter should be installed upstream to capture larger particulate matter and greatly increase the lifetime of the Entegris (or other) filter. For example, a Balston Disposable Filter Unit (DFU) would be ideal. This can be purchased directly from LI-COR, part number 300-01961. Figure 2 shows the two filters connected upstream of the LI-78xx gas inlet connection.

For short-term survey measurements with the Smart Chamber, as well as long-term deployments of the analyzer with either LI-COR or third-party chambers, the installation of a simple water trap upstream of the analyzer inlet affords additional protection, preventing liquid water from reaching the analyzer and allowing continued operation of the system should a small amount of water enter the sample line inlet. Such a trap may be a simple design based on a plastic container or glass bottle, as shown in Figure 3.

If this solution is implemented, you must consider the additional volume added to the closed loop system and response time when making flux measurements. Details of the additional volume can be accounted for by the flux software embedded in the Smart Chamber, and in SoilFluxPro, with user input of this volume provided during the measurement set-up process. The volume of the water trap will have at least two kinetic effects: 1) it brings additional air to the system, which dilutes trace gas entering the system from the soil surface and reduces the measured trace gas mole fraction rate of change; and 2) it creates a time delay in the onset of a monotonic concentration increase or decrease. Since there are negative consequences resulting from this approach, the additional volume should be minimized, while remaining effective as a water trap. Accurate fluxes can still be measured if the added volume is sufficiently small. It is also important to note that any water captured in the trap should be emptied regularly to avoid reaching the vessel outlet and risk water ingress to the LI-78xx instrument. If you are planning the use of such a trap in long-term experiments you should consider the development of an automated trap emptying system. Customers have developed such systems using float switches and optical sensors.

- For permanent, static atmospheric monitoring sites, the risk of ingress of liquid water is lower, but can occur in extreme circumstances.

- As such, designers of sampling systems operated at these sites may include a liquid alarm sensor upstream of the analyzer inlet. The alarm is used to trigger a relay and disable the main sampling pump, preventing liquid water from entering analyzers that are subsampling from the main sampling line. An example alarm sensor, widely used in the aforementioned application is the KS3 liquid sensor from M&C Techgroup - https://www.mc-techgroup.com/en/Product-category/Liquid-Alarm-Sensors/For-non-conductive-media-even-version-for-ex-zone-1/, Figure 4. For an example installation, see A. E. Andrews et al, Atmos. Meas. Tech., 7, 647–687, 2014.

Note: A liquid sensor is not intended to turn off the sampling pump inside the Trace Gas Analyzer or the LI-8250 circulation pump. It should be used to turn off an external sampling pump for atmospheric measurements.

Parts

The following components are available from LI-COR.

| Description | Part Number |

|---|---|

| Intake Air Filters | 9978-234 |

| Balston Filter (0.01 micron) | 300-01961 |

| Bev-a-line Tubing (¼” OD, ⅛” ID 15 m) | 8150-250 |