The amount of radiation incident on a given flat (not necessarily level) surface area varies with the angle of incidence. Lambert's cosine law says that the radiant intensity observed from an ideal diffusely reflecting surface is directly proportional to the cosine of the angle of incidence.

When radiation strikes a given surface area at a greater angle of incidence, less radiation is received on that surface (see Figure 5‑2). For instance, when radiation strikes a given unit area at a 60° angle of incidence, half as much is received compared to a 0° angle of incidence. The same amount of radiation is spread over more surface area at a 60° angle of incidence.

LI-190R Cosine Response

A cosine-corrected sensor follows Lambert's cosine law and provides the most accurate measurements of radiation on a flat surface from all angles. Cosine correction ensures accurate measurements under various conditions such as low light levels and low solar elevation angles. Accuracy in low light conditions is important for applications such as determining the light compensation point for photosynthetic plants.

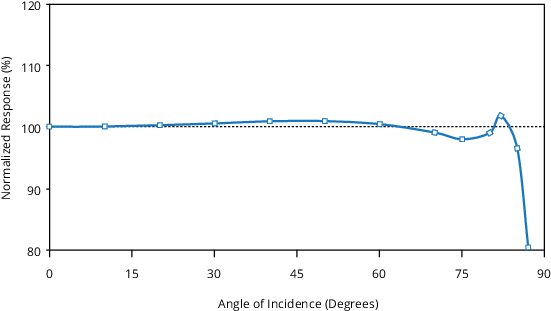

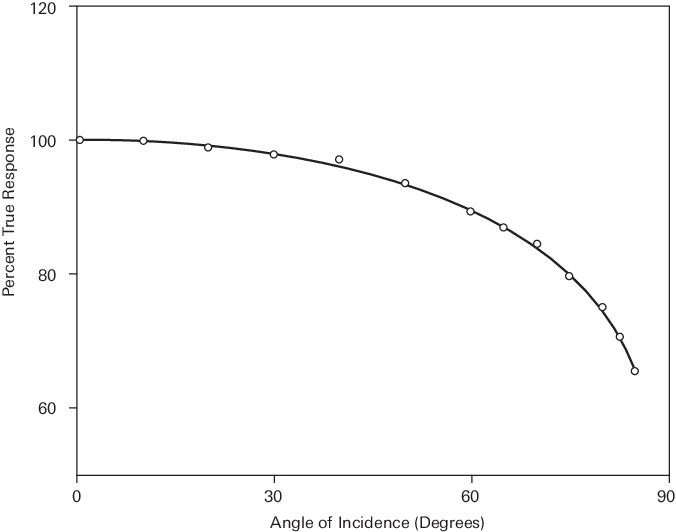

The LI-190R is fully cosine-corrected, with sensitivity to light nearly equal at all angles of incidence to about 82° angle of incidence (Figure 5‑1). Errors are typically less than ± 5% for angles less than 82° from the normal axis. At 90°, a perfect cosine response would be zero, and any error at that angle is infinite.

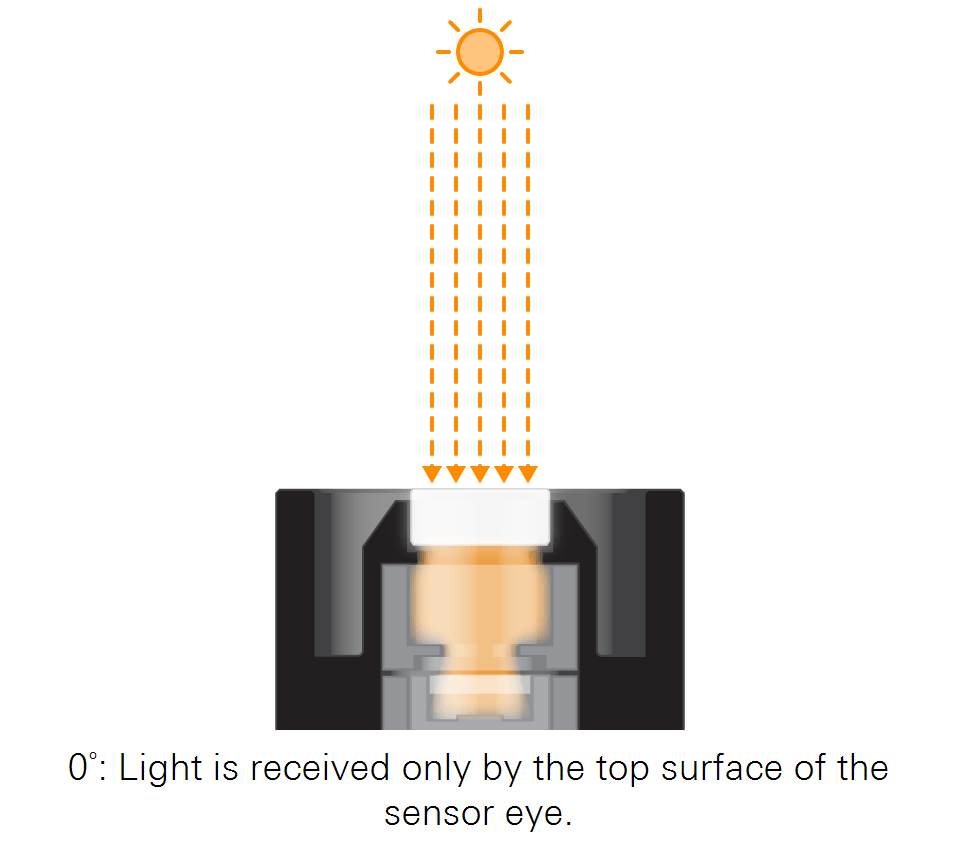

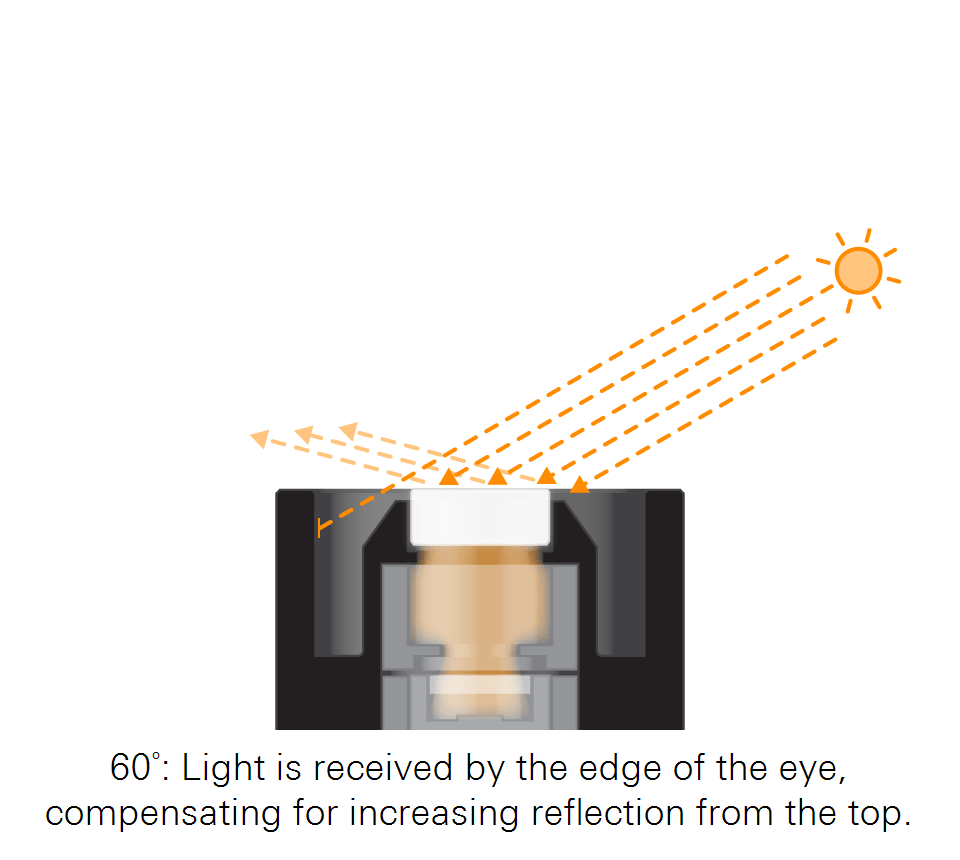

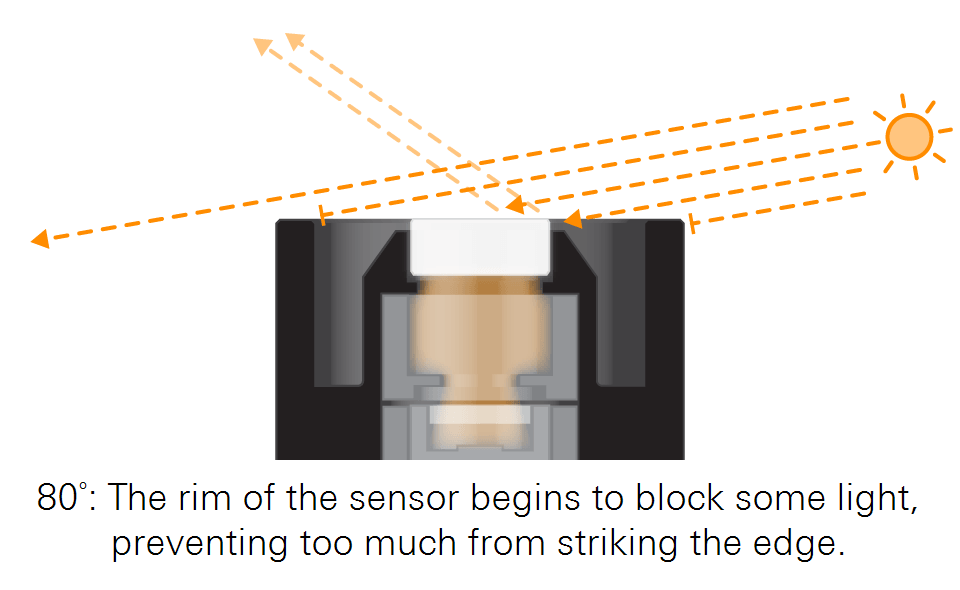

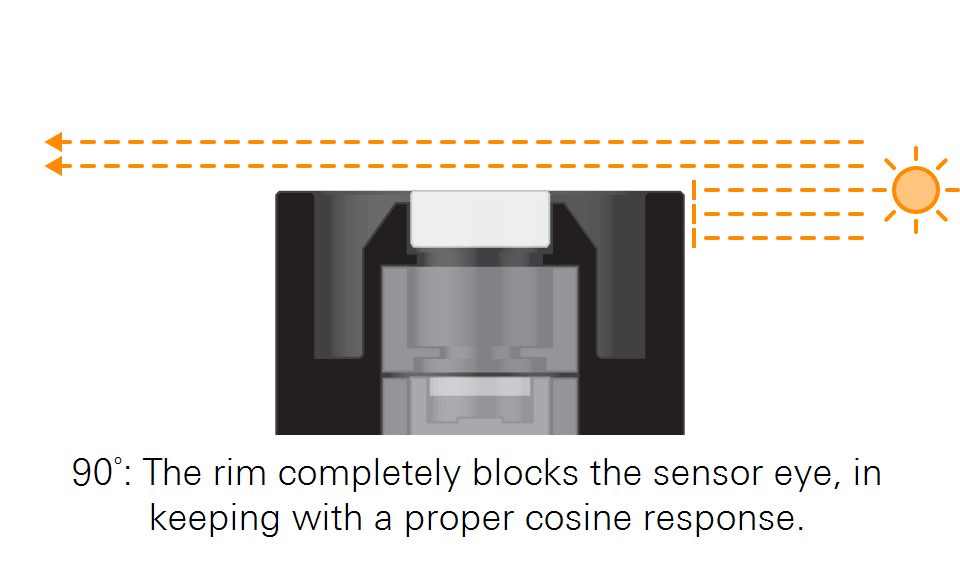

Figure 5‑2 shows how the design of the sensor creates the proper cosine response. Radiation is received by an acrylic disc called a diffuser, or eye. When radiation strikes with a greater angle of incidence, more is received by the edge of the eye. This compensates for increasing reflection from top surface as the angle of incidence grows larger. Beyond an angle of about 80°, the rim of the sensor begins to block some light in order to maintain the correct response as more radiation is received by the edge of the eye. At a 90° angle of incidence, the rim completely blocks the eye, in keeping with a proper cosine response.

LI-191R Cosine Response

Due to the linear, non-symmetrical sensing area, the LI-191R cannot be compensated completely for true cosine response. Figure 5‑3 shows the approximate cosine error for collimated light at angles of incidence from 0° (normal) to 90°.

Because the sensing area is a flat acrylic diffuser, the response at a given angle of incidence is fairly constant as the azimuth angle around the sensor is varied. It is specified at less than ± 2% at a 45° angle of elevation for 360° of sensor rotation.

Quantum Spectral Response

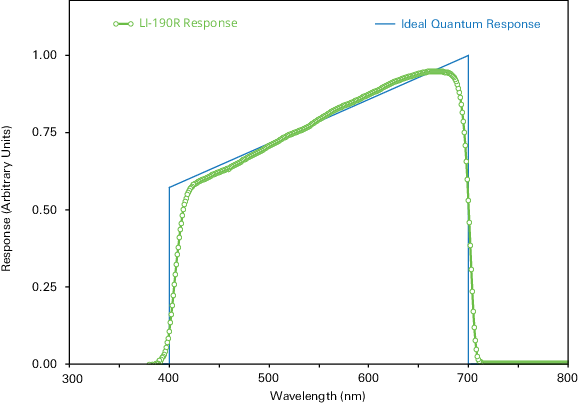

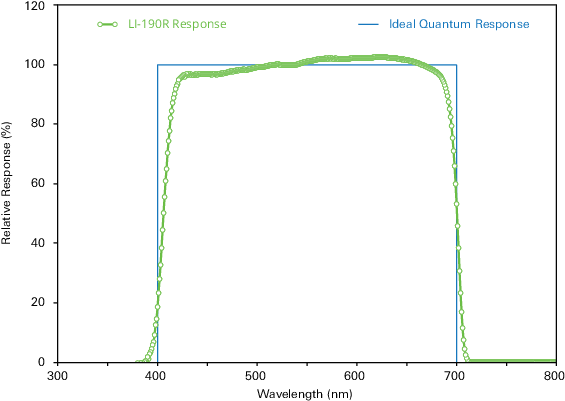

LI-COR quantum sensors measure photosynthetically active radiation (PAR) in the 400 nm to 700 nm waveband. This waveband was defined by McCree (1972)1 as producing a photosynthetic response in plants. Figure 5‑4 and Figure 5‑5 show that the quantum spectral response curve for the LI-190R is close to the ideal quantum response.

Calibration

Each LI-COR radiation sensor is fully calibrated at the factory, and no user calibration is needed. Acquire the calibration for your sensor by entering the serial number at licor.com/support/home.html. The recommended recalibration interval is every 2 years. Return your sensor to LI-COR for recalibration (see Factory Recalibration).

LI-190R Quantum Sensor Calibration

Each LI-190R Quantum Sensor is calibrated against a standardized lamp. The standardized lamp is calibrated against a National Institute of Standards and Technology (NIST) lamp. The photon flux density from the standardized lamp is known in terms of micromoles m-2 s-1. Uncertainty of the calibration is ± 5%, traceable to the NIST.

The following procedure is used to calculate the quantum flux output from the lamp. The lamp flux density () in watts m-2, in an increment at a wavelength can be expressed as

5‑1

where is the spectral irradiance of the lamp at wavelength (λ).

The number of photons s-1 m-1 in is

5‑2

where h is Planck's constant and c is the speed of light. This can be summed over the interval of 400 to 700 nm to give

5‑3

The result is adjusted to μmol m-2 s-1 by dividing by 6.022 × 1017.

LI-191R Line Quantum Sensor Calibration

The uncertainty of the LI-191R calibration is ± 10% due primarily to basic calibration limitations and a transfer error when calibrating the LI-191R against a reference quantum sensor and in a spatially uniform light beam. This method is required because of the large physical size of the LI-191R.

Calibration of the reference quantum sensor is performed on a specially equipped optical bench containing a high intensity quartz-halogen lamp traceable to the National Institute of Standards and Technology (NIST) standard lamps with known photon flux density and irradiance in the 400 nm to 700 nm waveband.