Measuring the subsample loop flow rate

Follow this procedure if you wish to have a more precise measurement of the subsample flow rate. See Mass balance in an open system for more details.

- Ensure the aquatic chamber pump is set at the speed you will use for measurements.

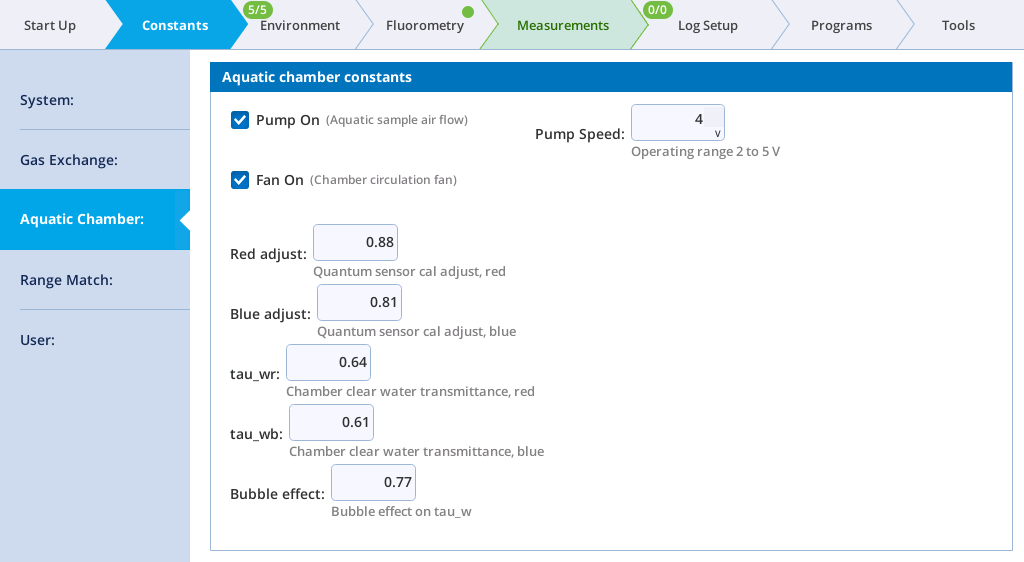

- Pump speed in the aquatic chamber is set via a control voltage under Constants > Aquatic Chamber > Pump Speed. The factory default value for this is 4 VDC. It can be set between 2 and 5 VDC.

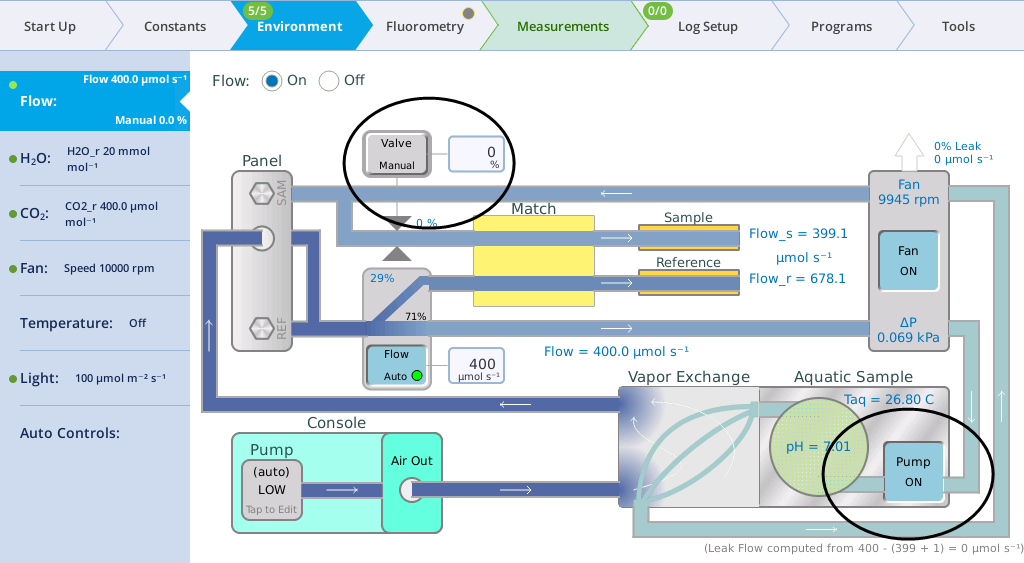

- Turn the aquatic chamber pump on (Environment > Flow). Set the chamber overpressure to off (Environment > Flow Valve = Manual and 0%).

- Fill the chamber with a volume of water comparable to your typical measurement sample volume. Insert the top plug.

- 15 mL is the nominal sample volume.

Note: Ensure that the chamber fill plug is in place. The chamber needs to be sealed and leak free for this test.

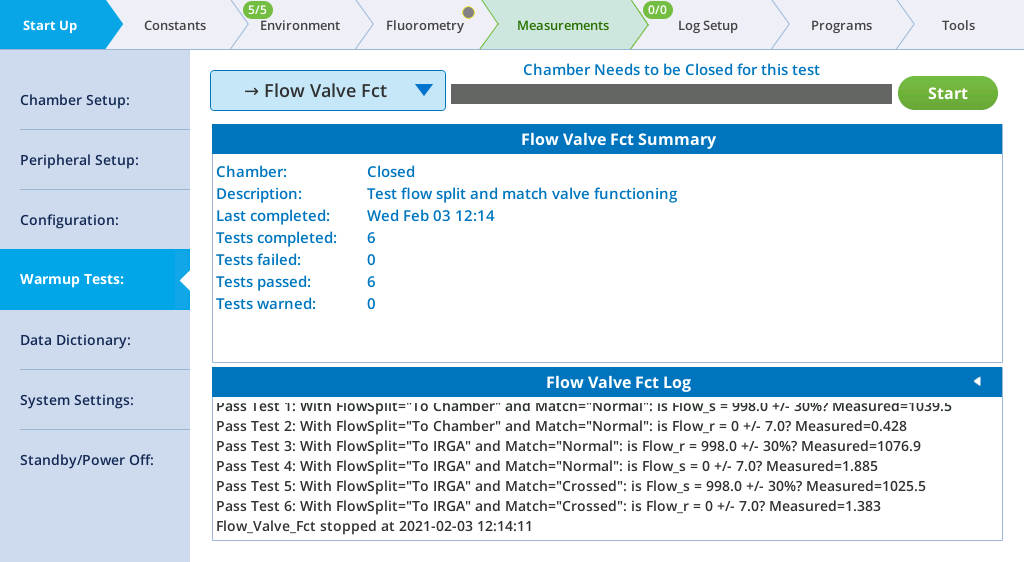

- Run the Flow Valve Fct test under Start Up > Warmup Tests.

- Set the instrument flow rate (Environment > Flow) to 800 µmol s-1.

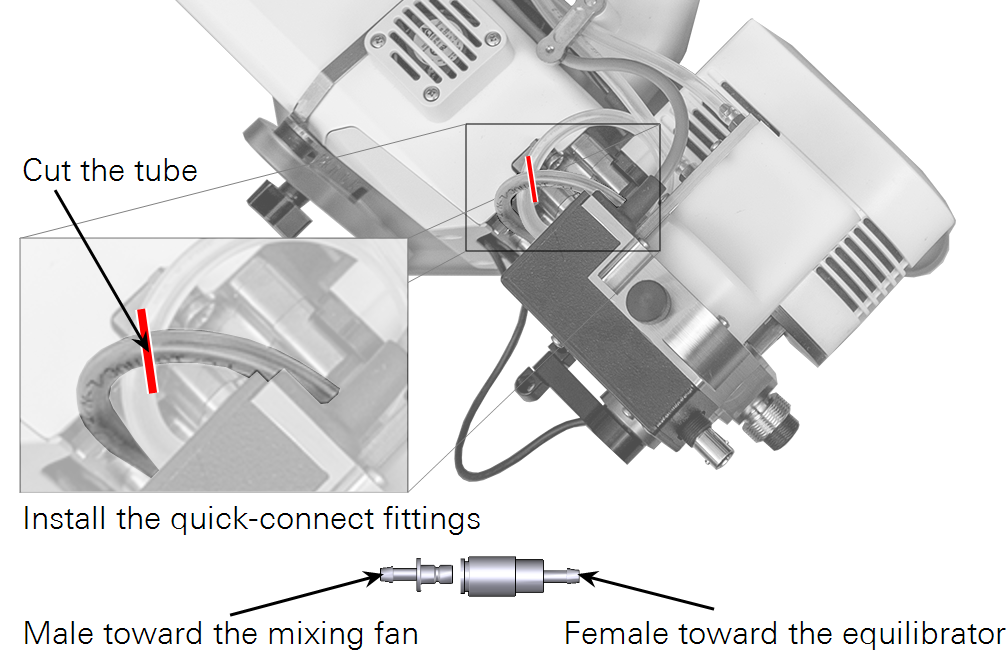

- Using a sharp knife or clippers, cut the tube that connects the water vapor equilibrator to the mixing fan volume.

- This tube connects to the hosebarb labeled 2 on the side of the water vapor equilibrator.

- Install quick connect fittings (300-07124 and 300-07125 in the spares kit) on the tube

- Connect the barbed end of the male fitting to the mixing fan side of the tube and the female fitting to the equilibrator side of the tube.

- Separate the connectors.

- Seal the end of the tube coming from the mixing fan volume with a piece of tape or just cover it with your finger. Leave the tube coming from the water vapor equilibrator vented to the atmosphere.

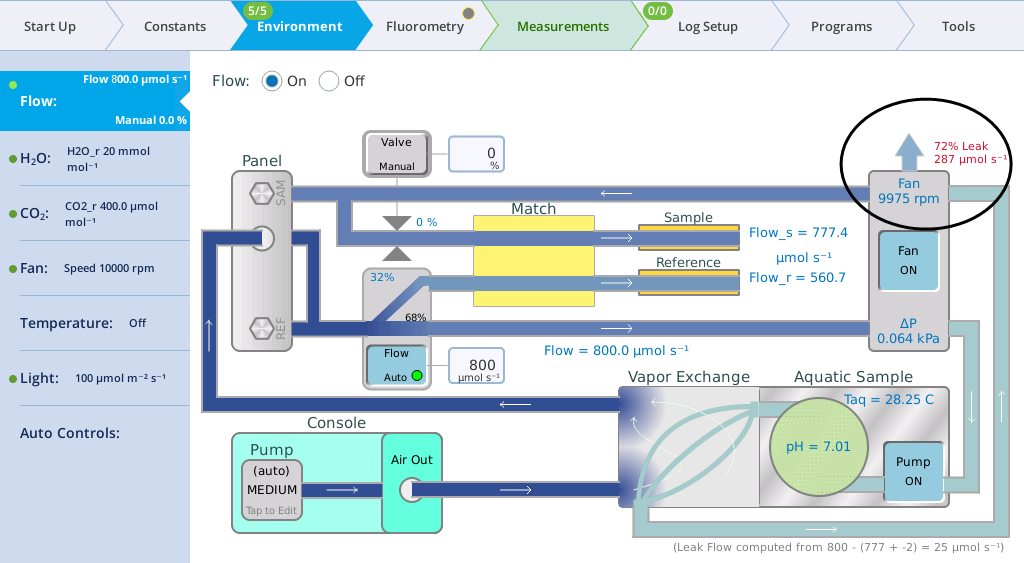

- Observe Flow_s reported on the flow control screen (Environment > Flow).

- Ensure that it is reporting a value above 300 µmol s-1. If not, make sure the tube from the mixing fan is sealed. If the tube is sealed and Flow_s is less than 300 µmol s-1, increase the flow rate a little at a time until the flow rate exceeds 300 µmol s-1.

- Observe the leak rate reported on the flow control screen.

- The reported leak rate (in µmol s-1) is the flow rate through the subsample loop of the aquatic chamber. This value is based on an internal calibration between Flow and Flow_s and gives a good estimate of the subsample flow rate (within ~3% compared to an independent measurement) when Flow_s is greater than 300 µmol s-1.

- Note that the absolute reading reported for Flow_s is uncalibrated and the sensor suffers significant uncertainties with slight pressure pulsations. Do not rely on its reported value to estimate the subsample flow rate.

- Reconnect the fittings on the tubes.