Controlling temperature with a water bath

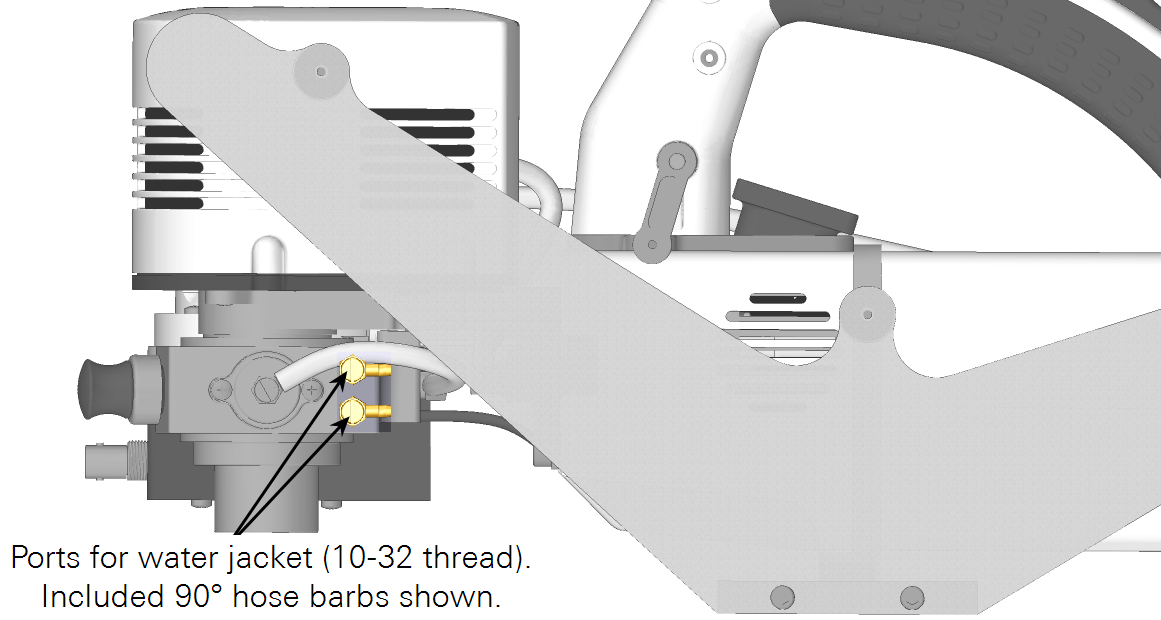

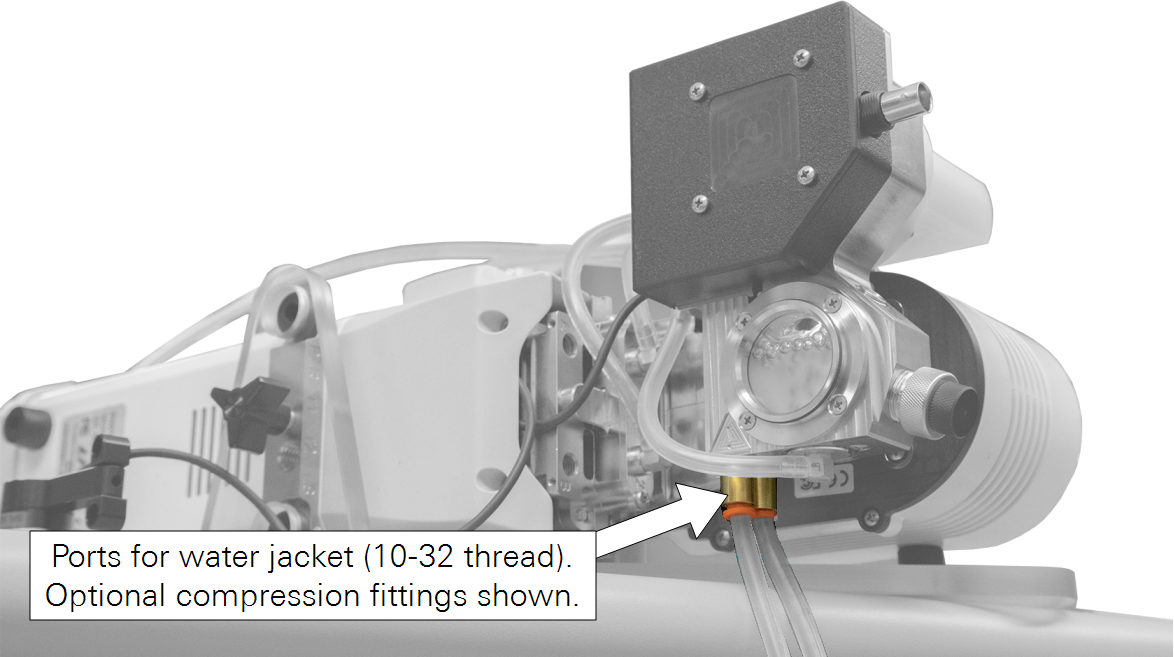

There are two ports on the bottom of the aquatic chamber to allow thermal control of the chamber block via a recirculating water bath. These ports are threaded to accept 10-32 machine threaded fittings. Figure 10‑27 shows the location of these ports. Note that no specific direction is required for water flow through these ports.

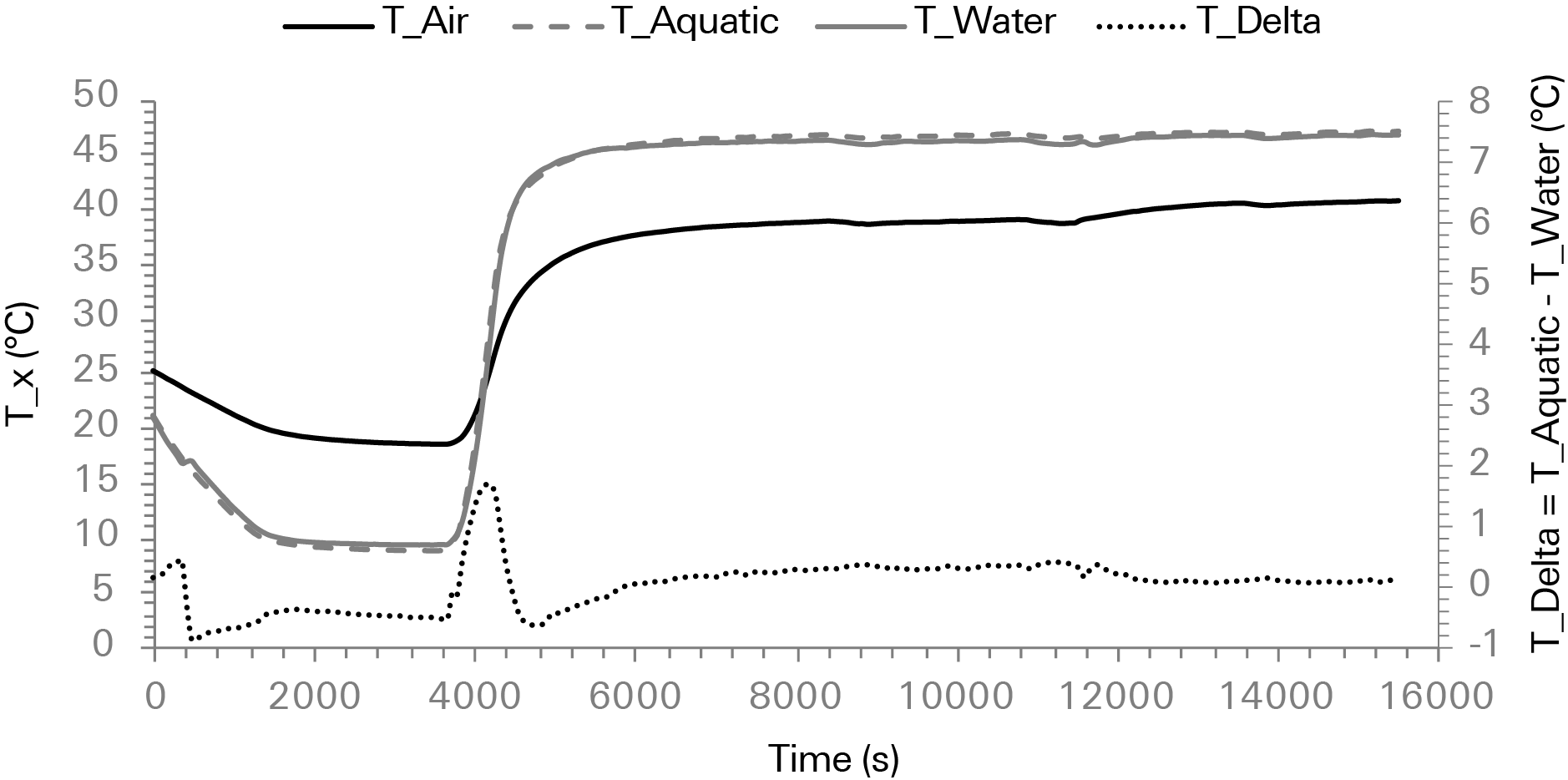

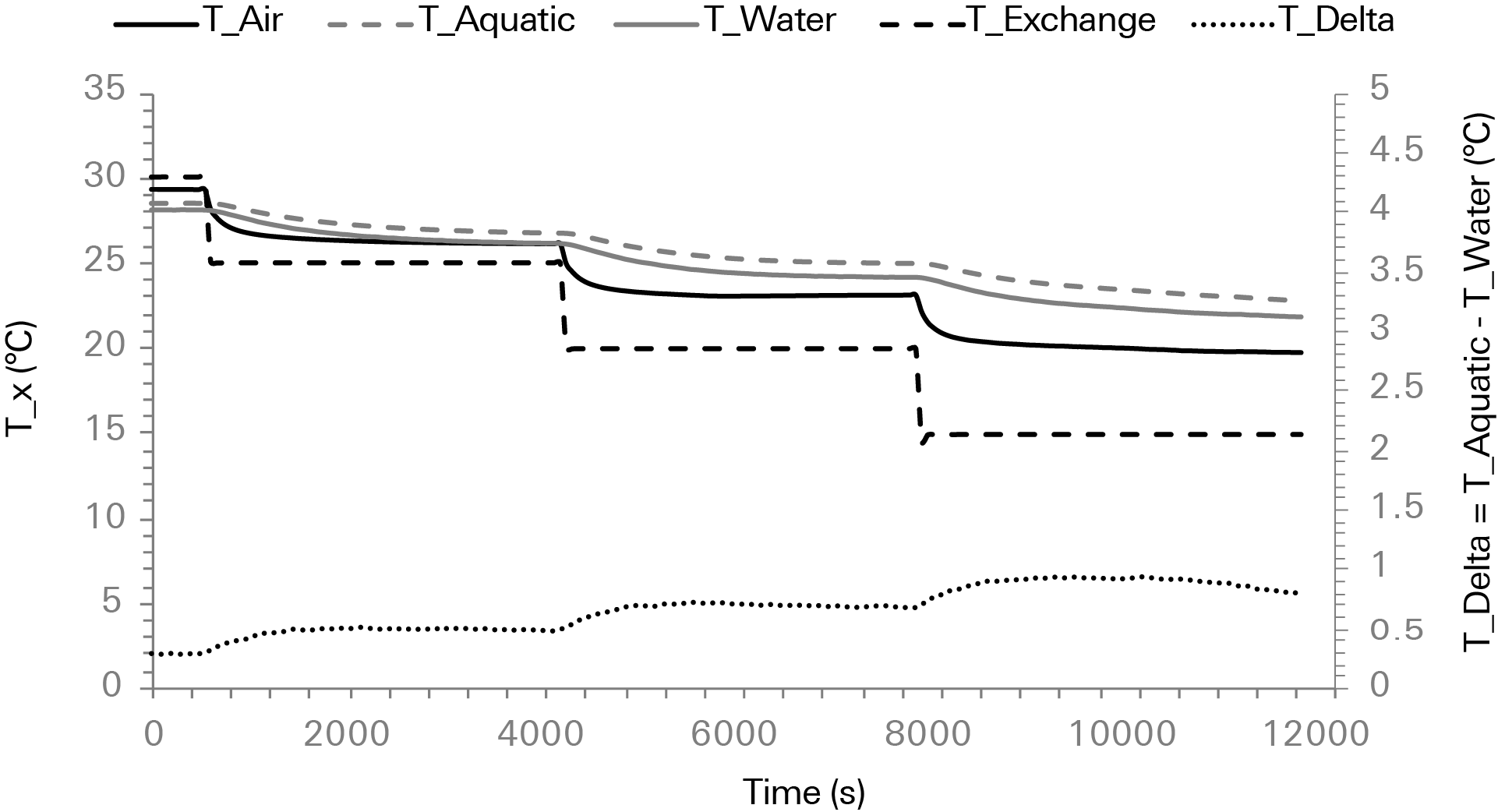

Thermal coupling between the aquatic chamber block and the liquid sample inside the chamber is quite good, as shown in Figure 10‑29 and Figure 10‑30. Here the measured temperature differential between the liquid sample (T_Water) and that of the aquatic chamber block (T_Aquatic) are typically within the expected accuracy of the measurement system used in these tests. Figure 10‑29 and Figure 10‑30 also show that there is some thermal coupling of the aquatic chamber to the air temperature inside the mixing fan volume of the LI-6800. This coupling is weak with a long time response, but may be useful in some situations where a recirculating water bath is not available and some degree of temperature buffering is needed. The impact of the mixing fan air temperature on the aquatic chamber is much more effective when heating the chamber above ambient, than it is when cooling below ambient. For precise temperature control, plumbing the chamber to a temperature controlled recirculating water bath is recommended.

Operation at temperatures above ambient

When operating the aquatic chamber at temperatures above ambient, liquid water may accumulate between the outlet PTFE membrane (16 in Figure 10‑2) and the water vapor equilibrator (17 in Figure 10‑2). For normal measurements this is generally not a problem as the equilibrator will prevent liquid water from exiting the chamber and continue to be able to bring the chamber exhaust air stream to a water vapor concentration below saturation (providing an appropriate water vapor control target is being used), protecting the rest of the sensor head and IRGAs. Here it is recommended to set the temperature exchanger to a control value at or just below the temperature of the aquatic chamber. If the chamber is to be stored following measurements at above ambient temperatures, ensure that everything is dry. Allow the pump to flow dry air through the empty chamber. You can blow out the tubing with a can of compressed air like those typically used to clean electronics. This will help eliminate any condensed water that has accumulated during measurements.

Operation at temperatures below ambient

When operating the chamber below ambient, the risk of condensation in the system is quite low as the air leaving the liquid sample will be at a dew point below ambient. Depending on how far the chamber is from ambient it is possible here for the water vapor gradient in the equilibrator to be reversed, such that it favors movement of water from the console flow to that of the sample. This situation should be avoided when possible, and a lower reference water vapor control target should be chosen such that the sample concentration is at or slightly higher than the reference. For the temperature exchanger control, this can be set to ambient or left off.