Leaks of liquid

The aquatic chamber can leak from the pH port, bottom perforated plate assembly, either window, or the septum if overfilled. If the leaking piece is not obvious, consider any parts that have been disassembled recently. Were they put together correctly?

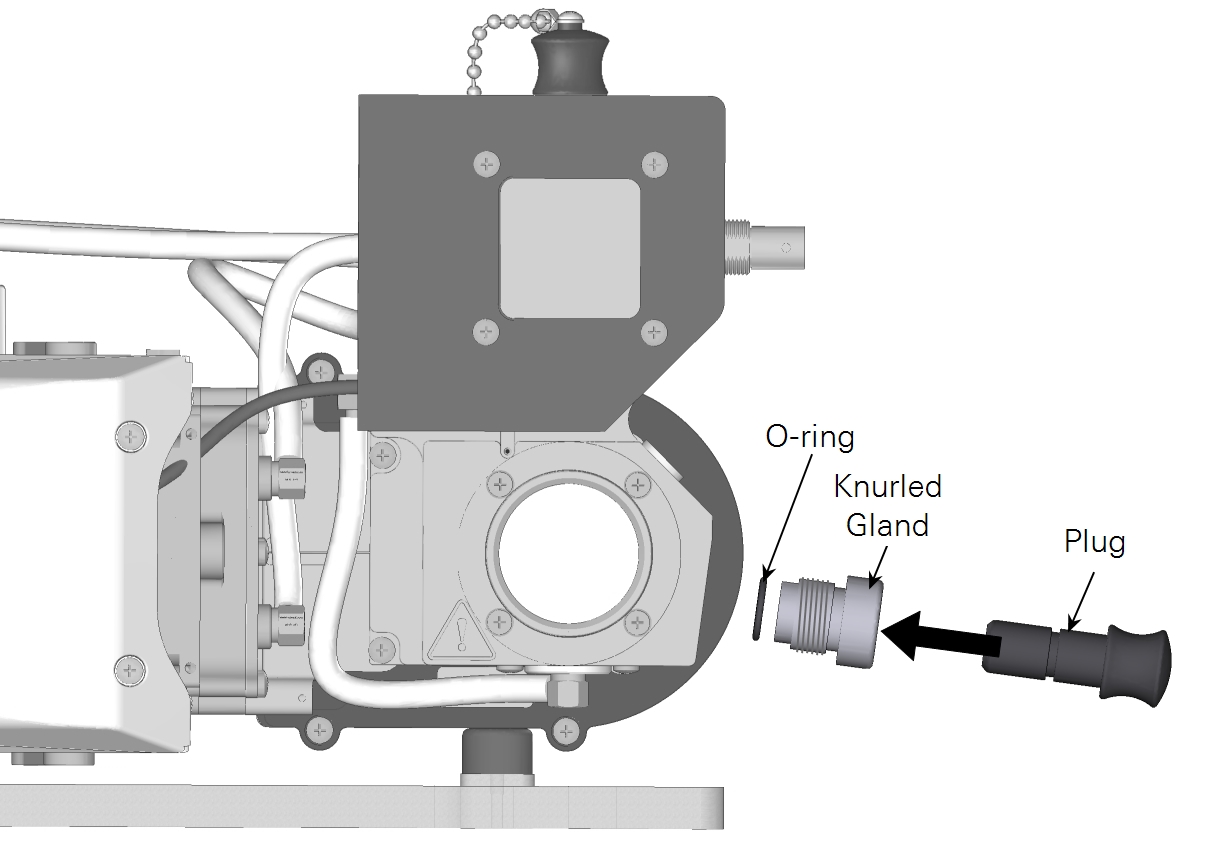

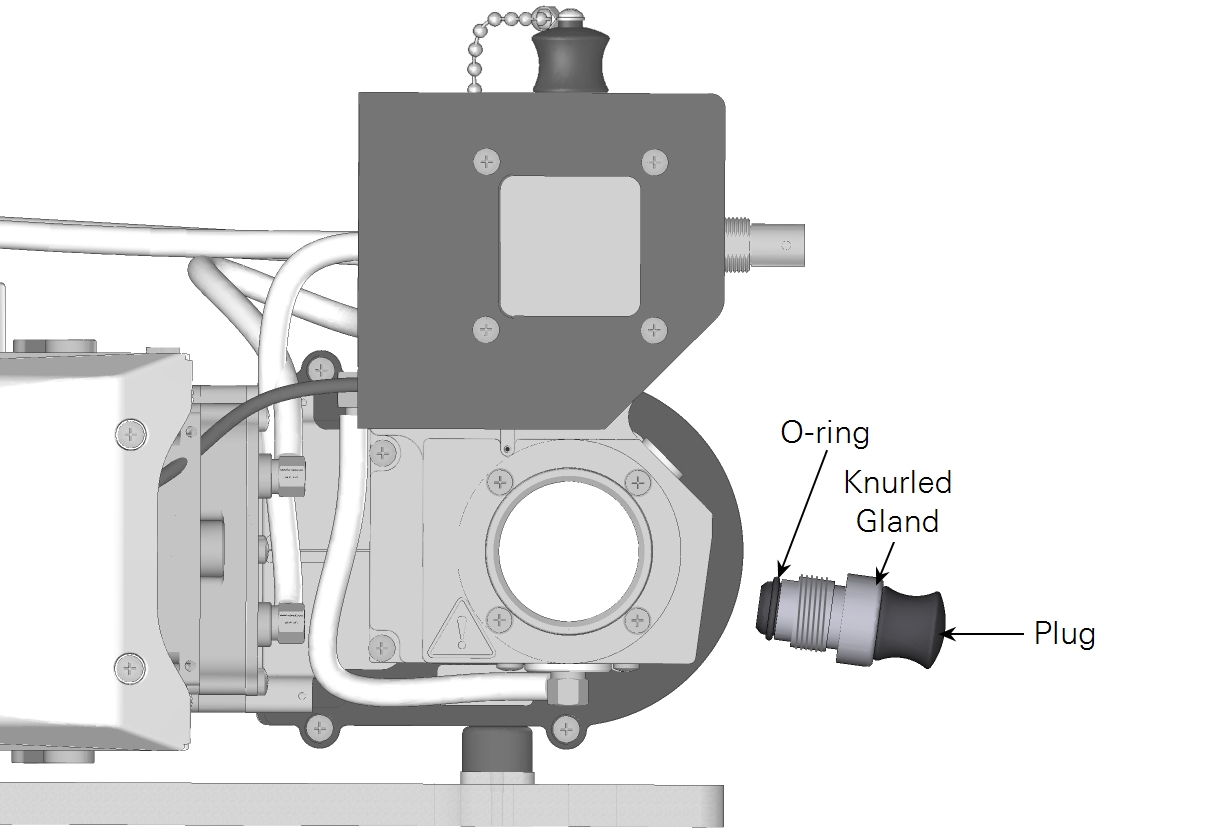

Leaks from the pH probe port

If the port is leaking, most likely, the plug or probe is not fully seated or the clasp is not tight enough. Press firmly on the plug to ensure it is all the way in, and tighten the knurled nut firmly. If it still leaks, the O-ring may have been pressed into the chamber volume or be damaged. Remove the plug, nut, and O-ring. Inspect the O-ring. If damaged, replace it with one from the spares kit (part number 192-18702).

Leaks near glass windows

The windows on each side of the chamber are secured with four screws. They are sealed with a single O-ring. Start by ensuring the screws that secure the windows are tight. If they are tight, but the leak continues, check the condition of the O-ring and replace it if necessary. A replacement is in the spares kit (part number 192-12027). See Cleaning chamber glass for disassembly details.

Leaks from the septum port

If this happens, it is likely that the sample volume is being overfilled. Try to use a sample that is 15 mL or smaller. The septum port can leak if the septum has been punctured with a large probe or if it is loose. See Replacing the septum for details.

Leaks from the cuvette air inlet

The air inlet to the bottom of the cuvette is sealed with an O-ring, but leaks can develop if the inlet cover is loose or if the O-ring is damaged. Follow the steps in Cleaning openings in the orifice plate for disassembly and cleaning instructions.

No or low flow through the perforated plate; perforations are blocked

Loading samples with the pump off or leaving sample in the chamber with the pump off will result in liquid contamination of the perforated plate and the lower PTFE membrane. This can block air flow through the lower membrane. In addition, liquid can enter perforations, causing them to become blocked. Cells may also accumulate in perforations. Any of these circumstances can result in constricted subsample flow.

If you observe an absence of bubbles through liquid even though the subsample pump is on (and audible), power off the instrument and follow the steps in Cleaning openings in the orifice plate and Replacing the orifice plate PTFE membrane to resolve the problem. To avoid a recurrence of the issue, always keep the subsample pump on when a sample is loaded, follow good cleaning practices between samples and at the end each day, and periodically disassemble the chamber to clean it and replace the PTFE membranes (if required) after extended use and before long term storage.