H₂O

Water vapor is set under the Environment > H2O tab. Here you can alter the humidity in the air stream by adding and removing water vapor.

The way you use these settings will depend on whether you are using a leaf chamber or the aquatic chamber

- See Leaf chamber software controls for details on leaf measurements.

- See Aquatic chamber software controls for details on aquatic measurements.

In addition to the buttons, you can tap the tube graphics to open the one-tap scale.

Controlling the H2O concentration

This exercise shows the range of water vapor concentrations that the instrument can establish. If using a leaf chambers. start with a closed chamber.

- Configure flow.

- Under Environment > Flow.

- Turn Flow: On

- Set the pump speed to Auto

- Set the flow rate to 700 µmol s‑1.

- Under Environment > H2O, set H2O to On.

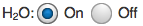

- Tap the RH_air button, then enter 50% in the RH_air box.

- Watch the display as the instrument adjusts the settings to achieve the relative humidity setpoint.

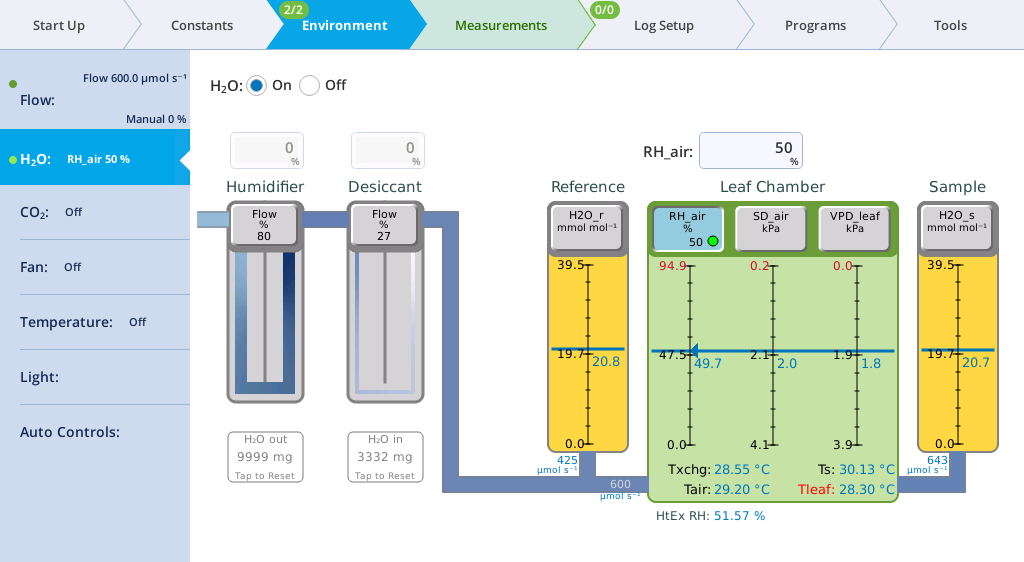

- Set the RH_air setpoint to 5% and observe the display as the instrument achieves the setpoint.

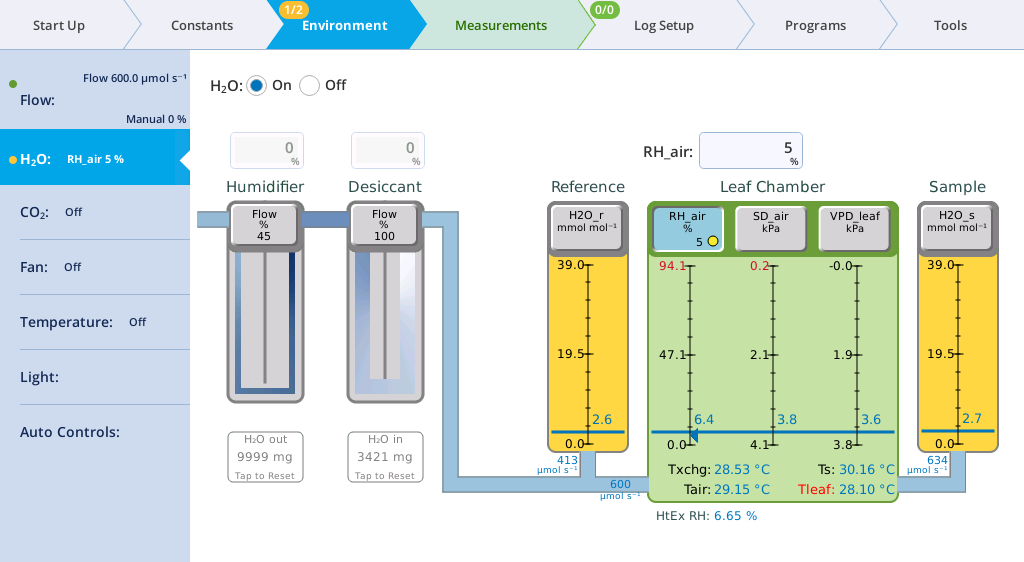

- Set the RH_air setting to 95% and observe the display as the chamber relative humidity approaches the setpoint. (95% is too high, but we are forcing the instrument to override the setting.)

- Notice that the instrument will not achieve the setpoint and it displays H2O SP Override. The instrument has limited the RH to prevent condensation in the chamber, gas analyzers, or heat exchanger.

- Now reset the RH_air setting to 50%.

Note: The LI-6800 mixing fan strips away the leaf boundary layer when the leaf is put into the chamber. It is important to keep the incoming H2O vapor concentration close to the concentration that is in the leaf's boundary layer before it is closed in the chamber This prevents the stoma from closing during the measurement. For typical leaf measurements, use a humidity setpoint between 50% and 85% or VPD between 1.0 and 1.5 kPa. Even leaves grown in dry environments achieve this range of humidity in their boundary layer.

Condensation protection

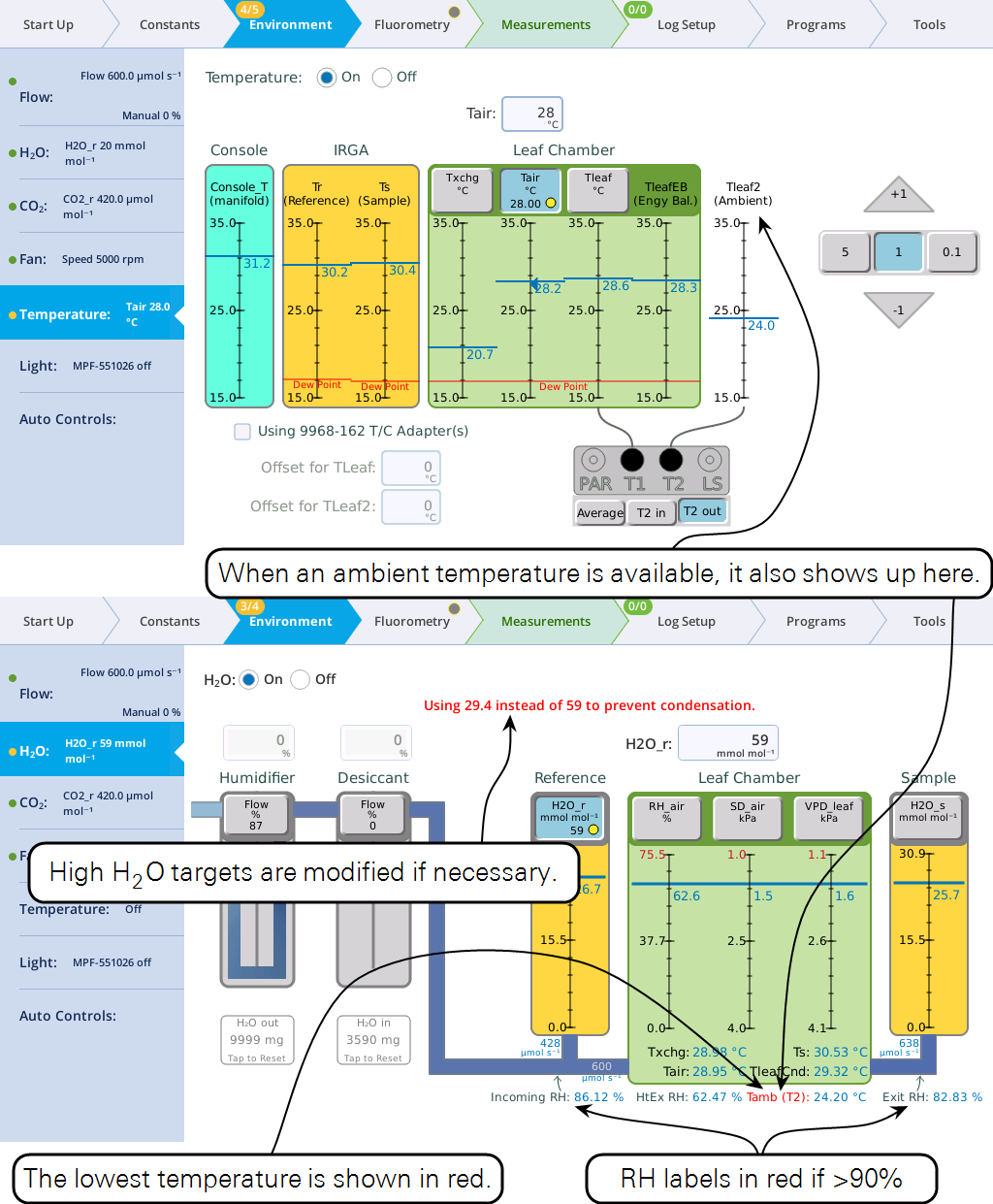

As air leaves the leaf chamber and flows toward the sample cell, it is exposed to near-ambient temperatures, and condensation is a risk if the chamber temperature is elevated. When the aquatic chamber is operated at above ambient temperature, there is an additional risk of condensation between the vapor exchanger and the sensor head inlet. Version 1.5 can address these issues when an ambient temperature measurement is available, which is easily done by plugging in a second thermocouple (Figure 3‑13) or, in the case of the aquatic chamber, just one (Figure 10‑18).

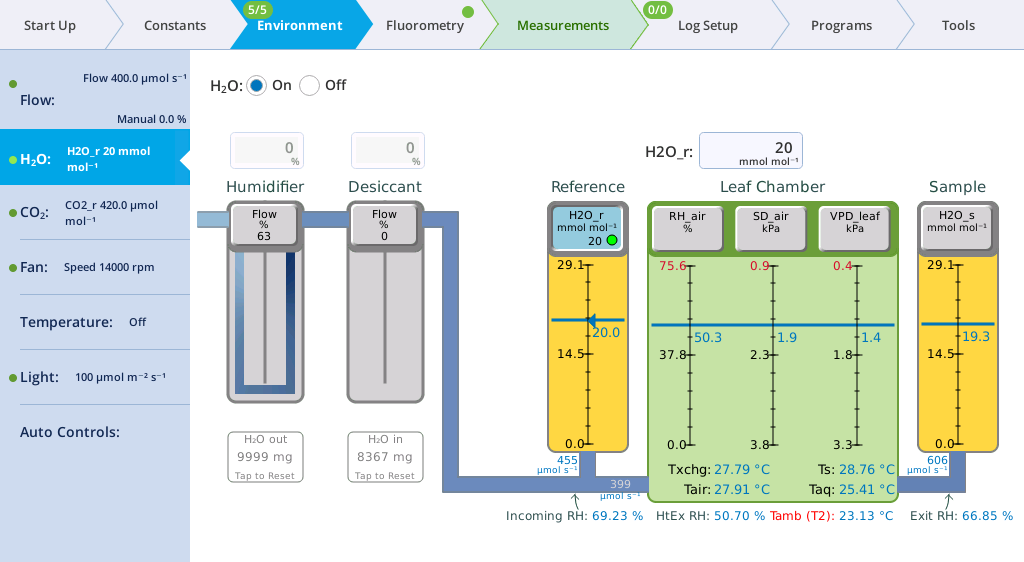

When Tambient is available, it will show up on the Environment > H2O screen, along with an Incoming RH and Exit RH, as illustrated in Figure 3‑13.

Selecting a temperature for the condensation check

Software version 1.1 introduces the ability to measure both Tleaf and Tleaf2. With two thermocouples, you can use one or the other, inside or out of the chamber, and averaging, which adds to the complexity. The LI-6800 uses TLeafCnd for the temperature, but what if we are averaging, or using energy balance, and want to communicate that one of the thermocouples is the limiting temperature, even though the average isn't? And there's one more thing: now that we have the ability to do flux-only computations, TleafCnd may not even exist. In the words of an old commercial, What's a mother to do? Make rules, of course, and here they are:

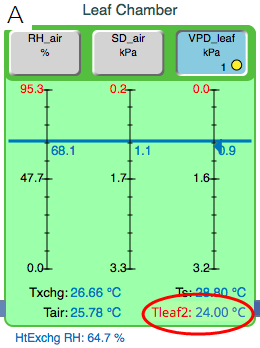

- If Tleaf or Tleaf2 (if in the chamber) become the humidity-limiting values, the label and value will reflect that (Figure 3‑14, A).

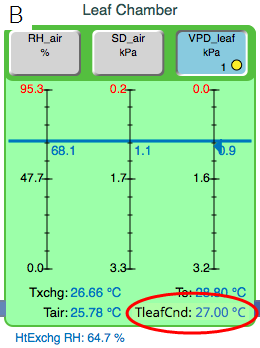

- If TleafCnd is being computed, and any in-chamber thermocouple is NOT the limiting temperature, then TleafCnd will be used (Figure 3‑14, B).

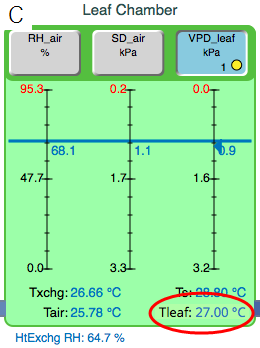

- If TleafCnd is not computed, the label and value will be (in order of priority) Tleaf, Tleaf2, or Tair (Figure 3‑14, C).