See this section for problems related to data quality or measurements.

Unexpected drift, shift in data values, or lack of responsiveness

Instrument stored in humid conditions? These symptoms may be expressed if the instrument has been stored in high-humidity conditions while powered off, which can cause humidity to saturate the detector. Let the instrument sit for several days powered on and the issue should resolve itself. If not, disassemble the gas analyzer and place the detector in an oven at 65 °C (150 °F) for several hours. Reassemble the instrument and check measurements.

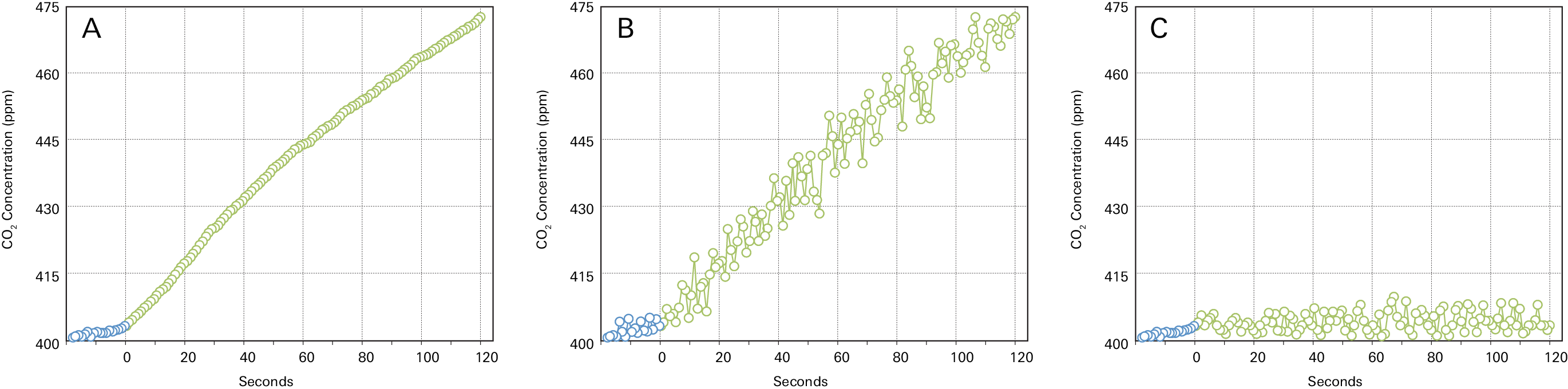

Noisy data

Chamber sealing properly around the collar? Check for obstructions that interfere with the chamber. Check the gaskets on the chamber and replace any damaged or hardened gaskets.

Cable and tube connections OK? Check the tubing and be sure everything is connected.

Leaky tube? Check the tubes for leaks, especially near the connectors.

Bad pump? Disconnect the tubes and feel for air movement. If you don't feel air movement, a call to technical support is a good idea.

Dirty or failed optical source? If the CO2 concentration is fluctuating wildly (especially going negative, which is physically impossible) or stuck on a certain concentration and not changing—even when you breathe into the Air In (especially -50 ppm), then open and clean the optical path first, as described in Cleaning the optical bench. If the issue continues, then check View > Instrument Status in the software or the app. If Operating Hours (or On Time Hours in the app) is around 18000, then you need to purchase a new 8100-902 infrared source. The infrared source starts to fail after about 18000 hours (around 2 years continuous use). Installation instructions are provide with the replacement, and can be downloaded from https://licor.app.boxenterprise.net/s/ihemfe24orwk232tikja.

High initial carbon dioxide concentrations

CO2 concentrations should be near ambient levels at the start of a measurement (around 400 ppm).

If using the multiplexer, is the pre-purge set to long enough? Lengthen this period and see if the problem is corrected.

Dead band set properly? Try to lengthen the dead band and see if that resolves the issue.

Low flow rate

Clogged filter? If you haven't replaced it in a while, it might be time.

Blockage or liquid water in a tube? Check all the tubes for water.

Bad pump? Disconnect the tubes and feel for air movement. If you don't feel air movement, a call to technical support is a good idea.

Unreasonable RH readings

The long tubes that connect the chamber to the multiplexer and gas analyzer, can affect H2O readings, especially because water vapor can adhere to the tube walls. This also means that there is a long distance from where water vapor is measured and where the temperature is measured. Therefore, the system can compute RH <100% sometimes, even if there is no problem.

Poor water vapor calibration? Check the zero and span, as described in Setting the zeros. Set them if necessary.

Accurate temperature measurements? If a temperature sensor is not working, or if the calibration values are incorrect, the temperature data may be incorrect. Incorrect temperature values may lead to inaccurate RH computations.

Unreasonable chamber temperature readings

Chamber cable not fully connected? Tighten the connector.

Chamber thermistor broken? If you are using the multiplexer, try swapping ports, chambers, and cables to isolate the problem.