Initial Setup

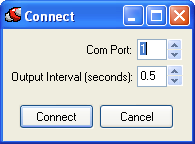

Choose a port and the output interval and click Connect. If the instrument is connected properly, data will begin to appear in the window:

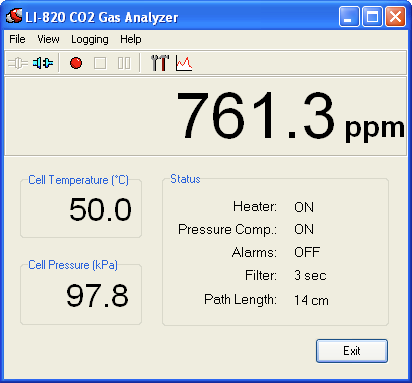

The Main window displays the CO2 concentration (ppm), as well as the status of various LI-820 parameters. There are also three menus used to configure the LI-820, perform zero and span calibrations, and set up the parameters for recording data. The LI-820 parameters in this window are as follows:

| Parameter | Description |

|---|---|

| Cell Temperature | Temperature (°C) in the LI-820 optical cell. This value should remain near 50 °C when the heater is turned ON. |

| Cell Pressure | Barometric pressure (kPa) measured in the LI-820 optical cell. This value can be used to correct CO2 measurements for the effects of pressure fluctuations on gas density. |

| Heater | Shows status of heater (ON/OFF), which is used to maintain the optical cell at a constant 50 °C. The heater is turned ON/OFF in the Settings window. |

| Pressure Comp. | Shows whether pressure compensation is ON/OFF. When ON, CO2 measurements are corrected for the effects of pressure fluctuations on gas density. |

| Alarms | Shows status of High and Low alarms, whose values are set in the Settings window. Alarms are enabled (ON), or disabled (OFF). |

| Filter | Shows the current value for software signal averaging, set in the Settings window. The filter can be set from 0 (no signal averaging) to 20 seconds. |

| Path Length | Shows the size of the optical bench installed in the LI-820, either 5.5 inches (14 cm), or 2 inches (5 cm). The 2 inch bench is no longer available, but may be present in older instruments. |

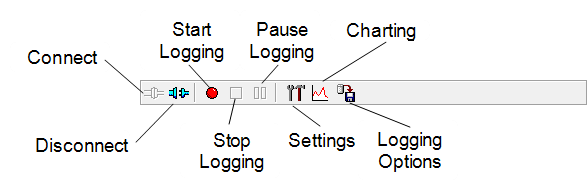

Using the Toolbar

The toolbar in the Main window contains shortcuts for some of the commonly used menu items:

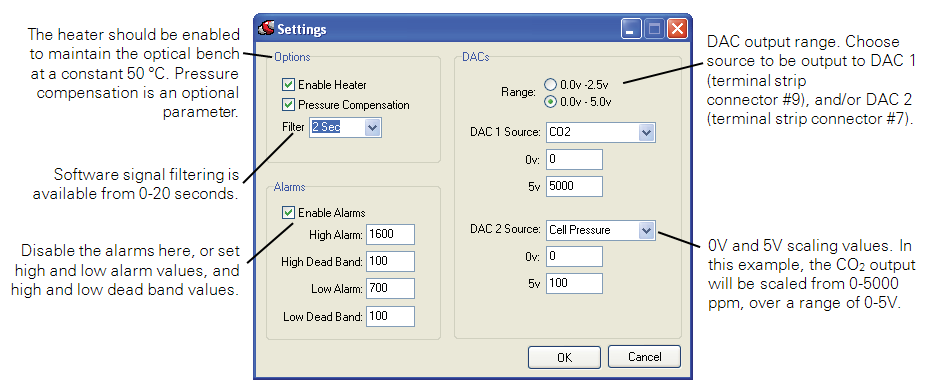

Settings Window - Setting Operational Parameters

The Settings window contains parameters related to initial setup of the LI-820, including signal filtering, high and low alarm setup, heater and pressure compensation options, and DAC output sources. Choose Settings from the View menu (or click on the toolbar icon) to open the Settings window:

Options

Enable Heater

The Heater should be enabled to maintain the optical bench at a constant 50 °C.

Pressure Compensation

Enable the Pressure Compensation check box to automatically correct gas concentration values for changes in cell pressure. In most cases this should be turned on; disabling this feature means that no pressure correction is desired in the gas concentration calculations, which can lead to erroneous measurements.

Filter

Shows the current value for software signal averaging. The filter can be set from 0 (no signal averaging) to 20 seconds.

Alarms

Allows you to enable/disable the alarms, and enter high, low, and dead band values. A complete discussion can be found in Section 2, Alarms.

DACs

Analyzer output for up to 2 values (CO2, Cell Temperature, or Cell Pressure) can be recorded by connecting a logging device to the terminal strip on the front of the analyzer. Output is linear, and is selectable at 0-5V or 0-2.5V. Choose the full scale voltage output range and the source for DAC 1 and/or DAC 2. Available output sources are CO2, Cell Temperature, and Cell Pressure. You can also choose a range over which to scale the output(s); you can achieve better resolution by scaling the output(s) over a narrower range, when appropriate.

The DACs in the LI-820 are bipolar, and will go slightly negative (~-0.100V). This can happen, for example, if the cell becomes contaminated or just from small random perturbations when the CO2 concentration is near zero. See Section 5, Cleaning the Optical Bench for instructions on cleaning the cell should it become contaminated.

Voltage output is measured by attaching the positive lead from the logging device to terminal 9 (V Out 1), or terminal 7 (V Out 2) on the LI-820 terminal strip. Connect the negative lead to position 10, (GND), or position

The CO2 concentration can be calculated from the DAC output voltage as follows:

where V is the measured voltage, XF is the full scale value for CO2 output (entered in the Settings Window as the 2.5 or 5 V value, up to 20,000 ppm), XZ is the zero value entered, and Vmax is the full scale DAC output voltage selected (5V or 2.5V).

Example: The DAC output range selected is 0-5V (Vmax), the zero CO2 value entered is 0 ppm (XZ), the full scale CO2 value entered is 2000 ppm (XF), and the measured output voltage (V) is 2.9 V. To calculate the CO2 concentration from equation 3‑1,

3‑2

= 1160 ppm.

Example 2: The DAC output range selected is 0-5V (Vmax), the zero CO2 value entered is 1000 ppm (XZ), the full scale CO2 value entered is 2000 ppm (XF), and the measured output voltage (V) is 2.9V. To calculate the CO2 concentration from equation 3‑1,

3‑3

= 1580 ppm.

Converting Voltage Output to Cell Temperature

Cell temperature can be calculated from the DAC output voltage as follows:

3‑4

where V is the measured voltage, XF is the full scale value for temperature output (entered in the Settings Window as the 2.5 or 5 V value, up to 100 °C), XZ is the zero value entered, and Vmax is the full scale DAC output voltage selected (5 V or 2.5 V).

Converting Voltage Output to Cell Pressure

Cell pressure can be calculated from the DAC output voltage as follows:

3‑5

where V is the measured voltage, XF is the full scale value for cell pressure output (entered in the Settings Window as the 2.5 or 5 V value, up to 115 kPa), XZ is the zero value entered, and Vmax is the full scale DAC output voltage selected (5 V or 2.5 V).

Converting Current Output to ppm CO2

Note that these channels mirror their respective voltage output channels; current output channel 1 uses the variable chosen for voltage output 1, and current output channel 2 uses the variable chosen for voltage output 2. Similarly, a voltage output of 0 volts corresponds to a current output of 4 mA, and when the voltage outputs are at full scale (2.5 or 5 V), the current output will be 20 mA.

Current output can be measured by connecting the positive input of the datalogging device to positions 11 or 13 (4-20 mA 1 or 4-20 mA 2), and the negative input to position 12 or 14 (GND). The current output at positions 11 and 13 is non-isolated, and is rated to drive a 250 ohm load.

To convert current output (i) to units of ppm CO2 in your computer or other output device, the following equation can be used:

3‑6

where i is the measured current, XF is the full scale value for CO2 output (entered in the Settings Window as the 2.5 or 5 V full scale value, up to 20,000 ppm), and XZ is the zero value entered.

Example: The zero CO2 value entered is 0 ppm (XZ), the full scale CO2 value entered is 2000 ppm (XF), and the measured current output (i) is 16.25 mA. To convert to ppm CO2:

3‑7

= 1531.25 ppm.

Using the Terminal Strip

The terminal strip is located on the front panel of the LI-820. To connect the wires, insert the bare wire end into the appropriate terminal and tighten the screw above that terminal using the small flat head screwdriver in the spare parts kit. The terminal strip can be removed to aid in connecting the wires by pulling straight out on the face.

The terminal positions are as follows, reading left to right:

| Terminal | Label | Description |

|---|---|---|

| 1 | 12-30 VDC | Voltage In, 12-30 VDC |

| 2 | GND | Ground |

| 3 | High Alarm | High Alarm |

| 4 | GND | Ground |

| 5 | Low Alarm | Low Alarm |

| 6 | GND | Ground |

| 7 | V OUT 2 | Voltage output channel 2 |

| 8 | GND | Ground |

| 9 | V OUT 1 | Voltage output channel 1 |

| 10 | GND | Ground |

| 11 | 4-20 mA 2 | Current output channel 2 |

| 12 | GND | Ground |

| 13 | 4-20 mA 1 | Current output channel 1 |

| 14 | GND | Ground |