CO2 Control

If you are using the 6400-01, then you should leave the soda lime knob on full scrub.

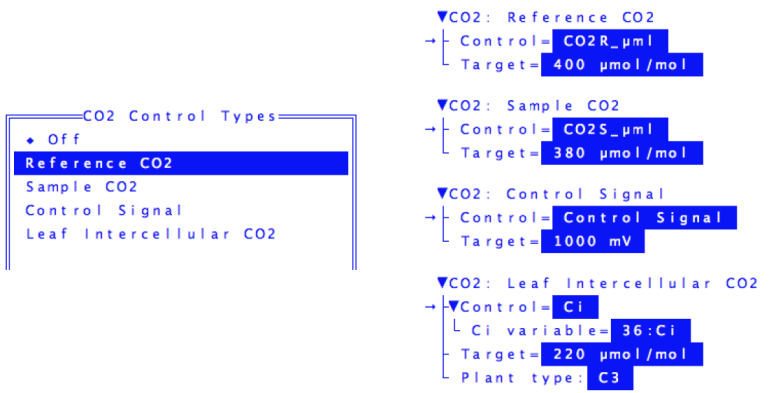

When f3 (level 2) is pressed in New Measurements mode, the following control options are presented:

| Option | Description |

|---|---|

| Off | Turns off the mixer. (It’s actually not turned off, but its output is switched out of the air stream and has no effect on the system’s CO2 concentration.) |

| Reference CO2 | Maintains a constant CO2 concentration in the reference cell. That is, the incoming chamber CO2 concentration is held constant at a target value. This is a good default option. |

| Sample CO2 | Maintains a constant CO2 concentration in the sample cell / chamber. |

| Control Signal | The mixer control signal is set and held at a target value. This is mostly a diagnostic tool. |

| Intercellular CO2 | Tries to maintain constant intercellular CO2 |

Reference CO2

Usually the preferred option is constant reference, or incoming CO2 concentration. When you enter a target concentration, the injector will adjust itself to bring the reference cell concentration to that value and hold it. Depending on how big the adjustment is between the present value and the one you want, it may take a few seconds or a few minutes to get there (going up always takes longer than coming down). Once the concentration is achieved, there is very little that will cause it to change,1 so maintaining it is usually not a problem. If it does drift more than 1.5 ppm, the software will attempt to bring it back on target.

Sample CO2

This option has the advantage of maintaining what the leaf actually “sees” as a constant, but it is not as tight a control loop. This is because there are things that affect this concentration that the control loop cannot control, like photosynthetic rate of the leaf, and flow rate through the chamber (the latter being fully in the domain of the humidity controller). All the CO2 controller can do is regulate CO2 concentration coming into the chamber, once those other things are stable.

For best results controlling Sample CO2:

- Start out with the constant Reference option

- Specify a target 20 or 30 μmol mol-1 above what you want in the chamber (to allow for photosynthesis), and wait for the system to stabilize.

- Switch to the S option

- Once things are stable, the controller can quickly lock in and hold a constant sample concentration. Subsequent targets can then be specified for the sample concentration, but if it really loses control, you can always drop back to the Reference option and bring things back under control.

Unlike the constant humidity control options, which depend on the leaf providing lots of water, the Sample option doesn’t depend on anything from the leaf, other than perhaps reasonably stable CO2 assimilation. In fact, it works well with no leaf at all (as long as the chamber is closed, of course2).

Interaction with Humidity Control

There is an interaction between the constant sample CO2 option, and the constant humidity control options. If the humidity controller is changing the flow rate to try to achieve some target humidity, the CO2 concentration in the leaf chamber is going to be responding as well. Generally this causes the CO2 controller (when it’s doing the Sample option) to wait until things stabilize, before attempting adjustments.

The result is that the Sample CO2 option will work with constant humidity control, but expect longer system equilibration times.

Control Signal

The Control Signal option has two purposes: as a diagnostic, and as an option that will provide the fastest equilibration time after a change in CO2 target. This option simply sets the controller to a target value (voltage, not CO2 concentration), and makes no further adjustment. Thus, when you specify a target, you may not know exactly what the final concentration will be. You will be assured the controller will be making no changes, so any change or fluctuation you see in reference CO2 concentration will be coming from something else (leaks, bad soda lime, total flow rate changes, long term drift of the controller, etc.).

Intercellular CO2

The Intercellular CO2 option is a bit of a different animal than the other options. Its purpose is to try to maintain a constant Ci in the face of other changes going on, such as during a light response curve. You should not try to generate a CO2 response curve with this control. Here’s why: Leaf intercellular CO2 is approximately (see equation 1‑18).

7‑3

where Cs is the sample cell CO2 concentration, A is photosynthetic rate, and g is conductance. Of the three terms on the right side of the equation, only Cs comes close to being directly controlled by the CO2 mixer, and even that is not direct, since it depends on flow rate and photosynthetic rate A. What really drives Ci is the ratio of A to g, and the CO2 mixer has no immediate affect on those. There are indirect effects, of course, and they can work against you. For example: suppose we start with Cs = 380, A = 20, and g = 0.1. That makes Ci = 380 - 200 = 180. Now suppose you want to make Ci go to 300. Your first guess might be to make Cs 500, since A/g is 200. So you do that. However, because Cs has gone up, A also goes up, and the stomates close a bit. Now we have A = 25, g = 0.07, and A/g is now 357, and that makes Ci only 143, and somehow we have gone the wrong direction.

So, use the Intercellular CO2 option to maintain Ci while changing light levels or other environmental variables; do not use it to do CO2 responses.

CO2 Mixer Calibration

There is a relation between the CO2 mixer’s control signal, and the resulting CO2 concentration measured in the reference cell. In fact you can see a plot of the relation that your instrument is currently using by selecting “Plot...” under “CO2 Mixer” in the Calib Menu. A typical plot is shown in Figure 18‑20.

The CO2 control software uses this calibration to come up with a first guess when you have specified some target CO2 concentration. If you find (when operating in constant reference concentration mode) that the first guesses do not seem very good, you can generate a new set of calibration points for it to use, described in 6400-01 CO2 Mixer.