Many simple problems may result from hardware or software configuration problems. If your system is not working as expected, refer to the following guide prior to calling technical support.

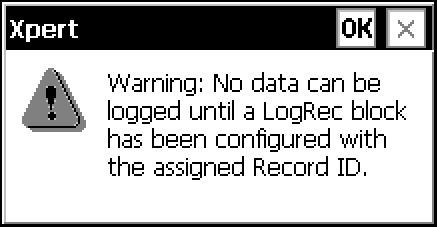

Warning Messages

Proper configuration? Edit the LogRec > RecordID or LogField > RecordID so they are the same. For example, if the LogRec > Record ID is "1", then the LogField > RecordID must be the "1" as well. See Custom Configurations.

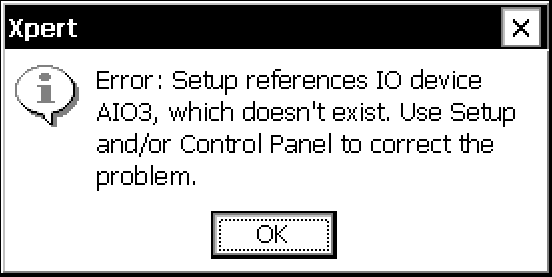

Be sure that each AIO module is properly identified in the datalogger program (see Add AIO Modules).

AIO modules not visible in software

Check the AIO module to datalogger RS-232 cable and connections. A straight-through cable is required.

Sutron datalogger power cycles continuously

Check the power supply. A 10 to 16 VDC power supply (9 to 30 VDC with backup battery/charge controller) is required.

Biomet data not embedded in .ghg files

If none of the biomet data are in .ghg files, this probably results from an improper network configuration. Check the software configuration of the datalogger and LI-7500A, LI-7500RS, LI-7200 and LI-7200RS. It could also result from improperly configured ComsTags in the datalogger. Confirm that they are configured appropriately. See Logging for EddyPro.

Logged data values appear unrealistic

View the data under the Sensors tab and follow the steps below to address the problem:

- Check the wiring and terminal connections. For a sensor that is reporting unrealistic values, first confirm that the wire leads are connected to the proper terminals and that the connections are tight.

- If the sensor is installed properly, confirm that the calibration values have been entered correctly (if applicable). You can verify and edit them by under the Data tab.

- Next, examine the wire lead connections for the suspect sensor. Exposed wires may come into contact with each other, thereby corrupting the signal. If this is the case, trim excess wire from the lead and reconnect the wires to the terminals.

- If the sensor is reporting no data, check again to be sure that the wire leads have not been inserted too far into the datalogger terminals. Be sure there is metal-to-metal contact between the leads, and that the datalogger terminals are not clamped onto insulation.

If none of the previous steps resolved the problem, it may be necessary to determine if the sensor is faulty. If you find a problem with a sensor, contact the manufacturer to determine the best course of action.