Tips for success

We begin with on overview of tips. With a little practice, you'll know exactly what to keep in mind when using the chamber.

Avoid condensation

Since the system is measuring a sample in liquid water and temperatures may be controlled at setpoints different than ambient, there is a risk of condensation in the system. It is important to take steps to mitigate this risk to protect the sensors, flow controls, and valves.

When sample temperatures are above ambient, there is high risk of condensation in the tubes because warm, humid air will be drawn through tubing that is at a lower temperature. Review Operation at temperatures above ambient and Operation at temperatures below ambient for more details.

Start with a fresh gas conditioning setup

The system tests will tell you if there are problems. To avoid failing the tests, be sure of the following:

- Unless you are using an external CO2 source, install a new CO2 cartridge at the beginning of each day. One cartridge will last about 8 hours after it is pierced, whether you use it or not.

- The humidifier column has water (liquid water in the column with Nafion™ tubing or dampened substrate in the column with Stuttgarter Masse).

- The desiccant is fresh. Sorbead Orange CHAMELEON is orange when dry and colorless when it needs to be regenerated (you'll learn "how orange" with experience). Indicating Drierite is blue when dry and pink when it needs to be regenerated.

- The CO2 scrubber is fresh. Indicating soda lime changes from white to violet as it becomes discharged.

See Filling the columns for more details.

Run the system tests

It is a good idea to run the tests after you have put everything together for the first time and any time something isn't working as expected. See Warmup tests.

Match the IRGAs

Given the small carbon dioxide differentials observed in typical measurements using the aquatic chamber on algal suspensions, careful matching between the reference and sample IRGAs is critical to getting good data. Testing thus far suggests that the performance of range matching is insufficient for most measurements with the aquatic chamber. Point matching at the current operating conditions is the recommended match procedure for the aquatic chamber. For the highest match quality, point matches should be performed after the water vapor delta has been minimized as far as possible, as described in Controlling water vapor in the aquatic chamber, and after the water vapor delta has stabilized. The matching options are described in Matching the IRGAs for aquatic measurements.

Avoid contamination

Preventing one sample from contaminating another is a relevant consideration. Triple rinsing the chamber with DI water is sufficient most of the time. For the most efficacious cleaning, remove as much sample as possible when you extract it, and remove as much rinse water as possible each time you rinse. Always have the subsample pump running when rinsing the chamber. Cleaning the chamber is a more extreme measure, but it should be done periodically and after periods of heavy use. The upper PTFE filter may accumulate cells, especially if not rinsed well between samples. If you are determined to avoid any risk of contamination, you can replace the upper filter between samples or after a few samples. See Replacing the H2O equilibrator PTFE membrane for details.

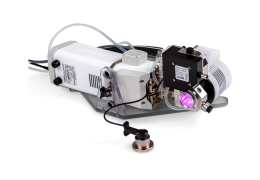

Loading a sample into the chamber

The subsample pump starts automatically when the instrument starts up. But if you have disabled it, start the subsample pump before loading the sample. Always keep the pump running when the chamber has media loaded. Only turn the pump off when the chamber is empty. Loading media while the pump is off may result in blocked air passages, requiring disassembly and cleaning of the chamber.

Avoid rapid injections when loading the chamber. This may result in blocked air passages, requiring disassembly and cleaning of the chamber.

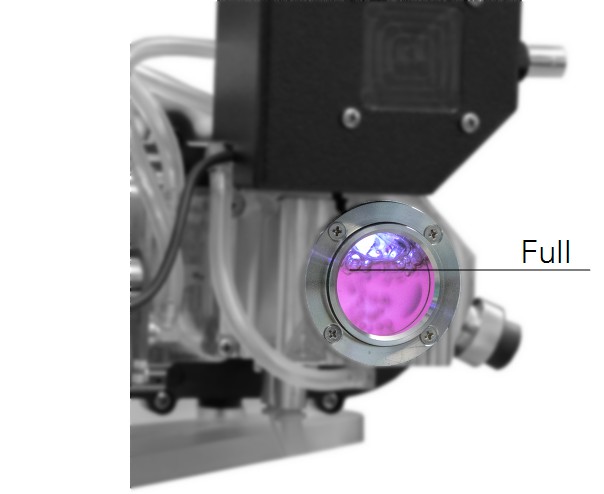

The chamber can hold a up to 20 mL of liquid. 15 mL is recommended sample volume. If foamy bubbles form above the sample to the extent that it might enter the headspace, use a smaller sample (13 mL) to prevent this.

Start each new measurement with a clean chamber. Triple-rinse the chamber with deionized water after each sample to avoid contamination of samples.

Finishing up after measurements

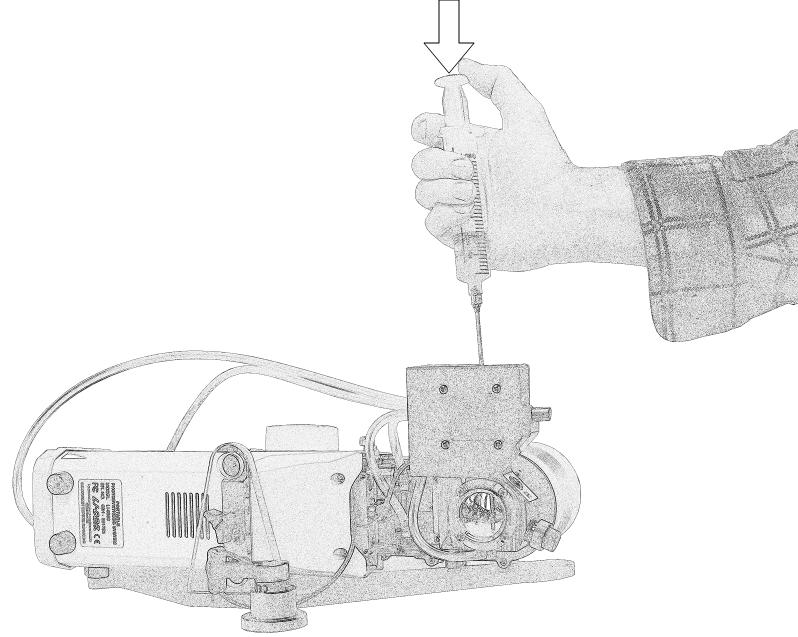

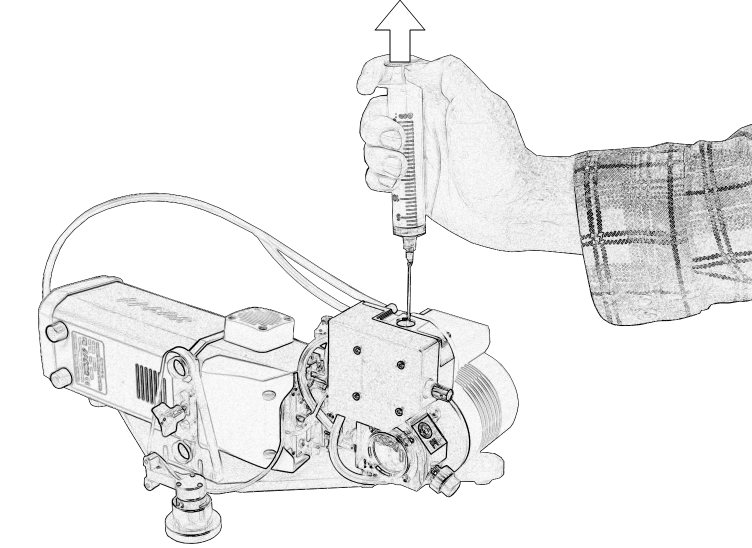

Keep the aquatic subsample pump running when there is a sample in the chamber. To remove the sample, insert the needle into the chamber until it makes contact with the bottom. Remove the light sensor aperture to see it through the glass. Draw the plunger up to remove as much liquid as possible.

Preserve a portion of the sample if you need to take additional measurements of cell density (Dcell), chlorophyll density (Dchl), and mass density (Dmass).

Triple rinse with deionized water after each sample. Each time you remove rinse water, extract as much as possible water with each rinsing.

At the end of a day, triple-rinse the chamber with DI water. Leave the cap off of the chamber so it can dry out. Download your data from the instrument and back it up.

If you have been controlling temperature using a water bath at levels above ambient, run dry air through the empty chamber for a few minutes to eliminate any condensed water that may have accumulated during measurements. You can blow out tubing with a can of compressed air like those typically used to clean electronics to help eliminate any condensed water that has accumulated during measurements. See Controlling temperature with a water bath for more information.

Loosen the CO2 cartridge holder to allow the gas to vent. Do not store the console in the case with a partially-used CO2 cartridge installed. The CO2 will vent into the case, filling it with very high concentration of CO2.

See Storing the LI-6800 for details about long-term storage.